In an era where technology and automation are rapidly transforming industries, the importance of reliable and innovative industrial connectors cannot be overstated. According to a report by MarketsandMarkets, the global industrial connectors market is projected to grow from $3.52 billion in 2020 to $5.91 billion by 2025, reflecting a compound annual growth rate (CAGR) of 10.4%. This growth is driven by the increasing demand for efficient data transfer and power connectivity in various applications, including manufacturing, transportation, and telecommunications. As industries continue to evolve, the need for advanced, durable, and versatile industrial connectors has led to the development of innovative solutions that may not yet be on your radar. In this blog, we will explore 10 innovative industrial connectors that you didn't know you needed, highlighting their unique features and potential applications in enhancing operational efficiency and reliability.

As industrial automation continues to rise, the demand for advanced connectors becomes increasingly critical, particularly in sectors like robotics, conveyor systems, and manufacturing. In fact, recent studies indicate that industrial automation currently accounts for approximately 70% of applications in the shifting gears and gear motor market, underlining its vital role in modern manufacturing processes. This shift towards automation not only enhances productivity but also paves the way for innovative solutions that improve efficiency and sustainability.

The push for sustainability is influencing the development of connectors that can support more energy-efficient machines and systems. Industry reports highlight that the global market for industrial connectors is expected to reach several billion dollars within the next few years, driven by advancements in connected devices and IoT technologies. This growth trajectory underscores the importance for manufacturers to invest in innovative connector designs that can meet the rigorous demands of automated applications while adhering to sustainability goals. The integration of these advanced connectors not only enhances performance but also aligns with global initiatives aiming to reduce energy consumption in the industrial sector.

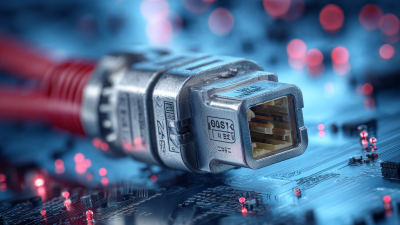

In the era of Industry 4.0, the significance of Ethernet connectors has risen dramatically as they weave seamless communication between machines and devices. These connectors enable the integration of IoT, facilitating real-time data exchange and enhancing operational efficiency. Ethernet connectors support high-speed connectivity, essential for handling the vast amounts of data generated by smart factories. They are not just about physical connections; they play a pivotal role in creating a robust network infrastructure that supports automation and intelligent systems.

Tip: When selecting Ethernet connectors for your applications, consider their durability and resistance to environmental factors. Industrial environments can pose challenges such as extreme temperatures, moisture, and dust. Opting for connectors with rugged housing and IP67 or higher protection rating can significantly prolong their lifespan and performance reliability.

Additionally, the versatility of Ethernet connectors allows for easy scalability in industrial setups. As production needs change, adding new devices or upgrading networks becomes a less daunting task. This flexibility supports the growing demand for interconnected systems and contributes to the overall agility of manufacturing processes.

Tip: Always assess the compatibility of Ethernet connectors with existing systems. Using connectors that adhere to standard protocols can save time and reduce integration costs, ensuring a smooth transition to modernized industrial operations.

In the dynamic landscape of manufacturing, hybrid connectors have emerged as a vital innovation, transforming energy efficiency across various industrial applications. By combining multiple functionalities into a single connector, these sophisticated devices facilitate the seamless transmission of power, signal, and data. This consolidation not only reduces the physical footprint of wiring systems but also minimizes energy loss typically associated with traditional connectors. As manufacturers strive for sustainability, the integration of hybrid connectors paves the way for smarter energy management and optimized operational efficiency.

Moreover, the versatility of hybrid connectors enhances flexibility in system design, allowing manufacturers to adapt to changing requirements with ease. By supporting a range of protocols and voltages, these connectors enable the integration of advanced technologies such as IoT and automation into existing frameworks without requiring a complete overhaul. As a result, companies can harness real-time data to monitor energy usage, predict maintenance needs, and ultimately reduce waste. The ongoing adoption of hybrid connectors is set to redefine industry standards, making energy efficiency not just an aspiration but a tangible outcome for modern manufacturing facilities.

| Connector Type | Key Features | Application Area | Energy Efficiency Impact |

|---|---|---|---|

| Hybrid Power/Data Connector | Integrates power and data lines | Robotics | Reduces cable clutter, enhancing energy flow |

| Quick Connectors | Tool-less connection and disconnection | Manufacturing Equipment | Improves uptime, reducing energy waste |

| Field Mountable Connectors | Customizable installation on-site | Outdoor Equipment | Minimizes downtime during setup |

| Sealed Connectors | Water and dust resistance | Harsh Environments | Enhances reliability, reducing maintenance |

| Smart Connectors | Integrated sensing technology | Smart Factories | Optimizes power usage dynamically |

| High-Voltage Connectors | Handles high power loads | Energy Sector | Improves energy transfer efficiency |

| Optical Fiber Connectors | High-speed data transmission | Telecommunications | Reduces energy loss during data transfer |

| Multi-Function Connectors | Combines multiple functions in one | Manufacturing Automation | Streamlines design, lowering energy overhead |

| Wireless Connectors | Eliminates the need for physical wires | Mobile Equipment | Reduces energy costs and enhances flexibility |

| Self-Locking Connectors | Prevents accidental disconnections | Assembly Lines | Increases process reliability, boosting efficiency |

Customized industrial connectors have emerged as pivotal components in enhancing operational efficiency across various sectors. According to a report from MarketsandMarkets, the global connector market is projected to reach $82.4 billion by 2025, fueled by the increasing demand for tailored solutions that cater to specific industrial requirements. These connectors not only optimize electrical connections but also mitigate downtime, which can be a costly issue for many manufacturers. A study by the Industrial Internet Consortium indicates that unplanned downtime can amount to over $250,000 per hour in manufacturing settings, underscoring the necessity for reliable connectivity solutions.

The impact of customized connectors extends beyond just reducing downtime; they also enhance overall productivity. With advancements in design, these connectors can be made to withstand harsh environments, ensuring uninterrupted service in demanding conditions. The adoption of specialized connectors can lead to efficiency improvements of up to 30%, as reported by the National Institute of Standards and Technology (NIST). This boost in productivity is crucial as industries strive to meet increasing output demands while maintaining cost-effectiveness. By investing in innovative, tailored connector solutions, companies can fortify their operational frameworks and drive sustained growth in an ever-evolving marketplace.

The integration of wireless industrial connectors and the Internet of Things (IoT) is shaping the future of connectivity in remarkable ways. With the AISG connector market projected to reach a value of $106.08 million by 2025 and $116.89 million by 2033, a compound annual growth rate of 1.22% signals the immense potential of this sector. Industries are increasingly recognizing the necessity of adopting next-generation connectivity technologies, particularly as the deployment of 5G accelerates across the globe and in China, presenting both challenges and opportunities.

Additionally, the market for Internal Wireless (IBW) systems is anticipated to grow significantly, with projections indicating an increase from 16,475.6 million in 2025 to 53,273.3 million by 2033, reflecting a robust compound annual growth rate of 15.8%. This surge is indicative of a broader trend towards Industry 4.0, where predictive maintenance and enhanced data transparency are no longer luxuries but essential components of operational efficiency. The growth of communication protocols such as IO-Link exemplifies the shift towards smart automation, enabling direct communication between sensors and actuators, ultimately fostering a more interconnected industrial landscape. As we stand on the brink of this communication revolution, the future of industrial connectivity promises to be both innovative and transformative.