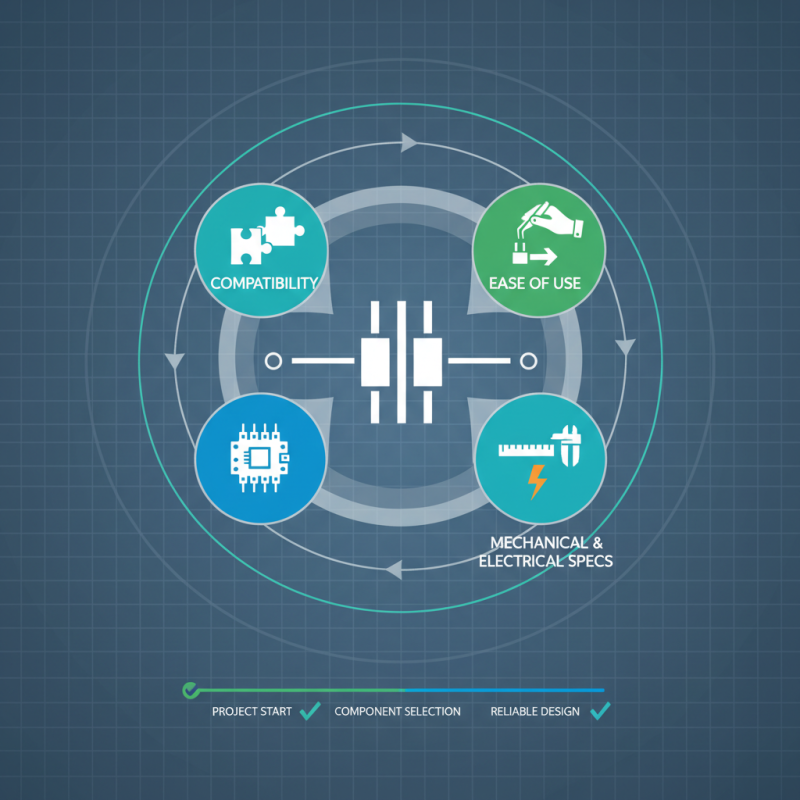

When embarking on an electronics project, the selection of the appropriate components is crucial for achieving optimal performance and functionality. Among the various components available, the 4 Pin Header Socket stands out as a vital connection point in many circuits. This seemingly simple component can influence the overall success of your project, making it imperative to choose the right type for your specific application.

In this guide, we will explore the key factors to consider when selecting a 4 Pin Header Socket, such as compatibility with components, ease of use, and the mechanical and electrical specifications required for your project. Understanding these considerations will empower you to make informed decisions, ensuring that your electronic designs are reliable and efficient. By the end of this article, you will have a comprehensive understanding of how to select the ideal 4 Pin Header Socket that fits seamlessly into your electronic endeavors.

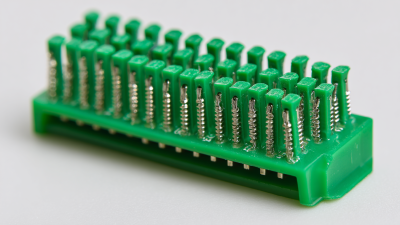

When diving into the world of electronics, understanding the basics of 4 pin header sockets is essential for ensuring your project’s success. These components serve as a crucial means of connecting various parts of a circuit, allowing for the transfer of power and signals between devices. Typically, a 4 pin header socket consists of four holes designed to accommodate corresponding pins on a connector. This simple yet effective design is widely used in a variety of applications, from microcontrollers to sensors, making it a favorite among hobbyists and professionals alike.

When selecting a 4 pin header socket, it’s important to consider factors such as pin pitch, mounting type, and current rating. Pin pitch refers to the distance between the centers of adjacent pins, which can affect compatibility with other components in your project. Additionally, header sockets may come in through-hole or surface mount variations, each offering distinct benefits based on your assembly needs. Lastly, ensuring that the current rating meets the requirements of your application will help prevent potential issues related to overheating or failure. By grasping these fundamentals, you can make an informed choice that enhances the functionality and reliability of your electronic designs.

When selecting a 4 pin header socket for your project, understanding the specifications that align with your needs is essential. One of the first factors to consider is the pin spacing. Common options include 2.54 mm and 1.27 mm. The pin spacing will affect compatibility with your circuit board, so it’s vital to measure the existing headers or the footprint in your design to ensure a perfect match.

Another important specification to assess is the current and voltage ratings of the socket. Each project has unique power requirements, and selecting a socket that can handle these demands is crucial for reliability and performance. Additionally, the material used for the pins and housing plays a significant role in durability and conductivity. Look for sockets made of materials that can withstand your project’s environmental conditions, such as temperature fluctuations and humidity, to avoid premature failure or connection issues.

When selecting the appropriate 4 pin header socket for your project, it’s crucial to evaluate the various types available in the market. According to a report by MarketsandMarkets, the global market for connectors, including header sockets, was valued at approximately $65 billion in 2022, with a projected compound annual growth rate (CAGR) of 4.3% through 2027. This indicates a growing demand for versatile connectivity solutions, which emphasizes the need to choose the right socket that suits your specific application.

Firstly, consider the different configurations of 4 pin header sockets, such as single, dual-row, and angled types. Each configuration has unique advantages, depending on the layout and space constraints of your project. For instance, dual-row sockets are often favored in applications requiring high-density connections, whereas angled sockets can save space and facilitate easier access in cramped environments. Furthermore, the materials used in the sockets, such as plastic housing and gold-plated contacts, can affect not only the performance but also the durability and longevity of the connections, as highlighted in a study by Allied Market Research which identifies quality components as key to reliable electronic assembly.

Additionally, assessing the current rating and voltage specifications is vital to ensure compatibility with your project’s requirements. The International Electrotechnical Commission (IEC) suggests that using components rated beyond your project's maximum demand helps mitigate risks of failure. With advancements in manufacturing processes, newer sockets are being designed to withstand higher thermal and electrical stresses, enhancing efficiency. Therefore, meticulously evaluating the types and specifications of 4 pin header sockets will significantly contribute to the success of your electronics endeavors.

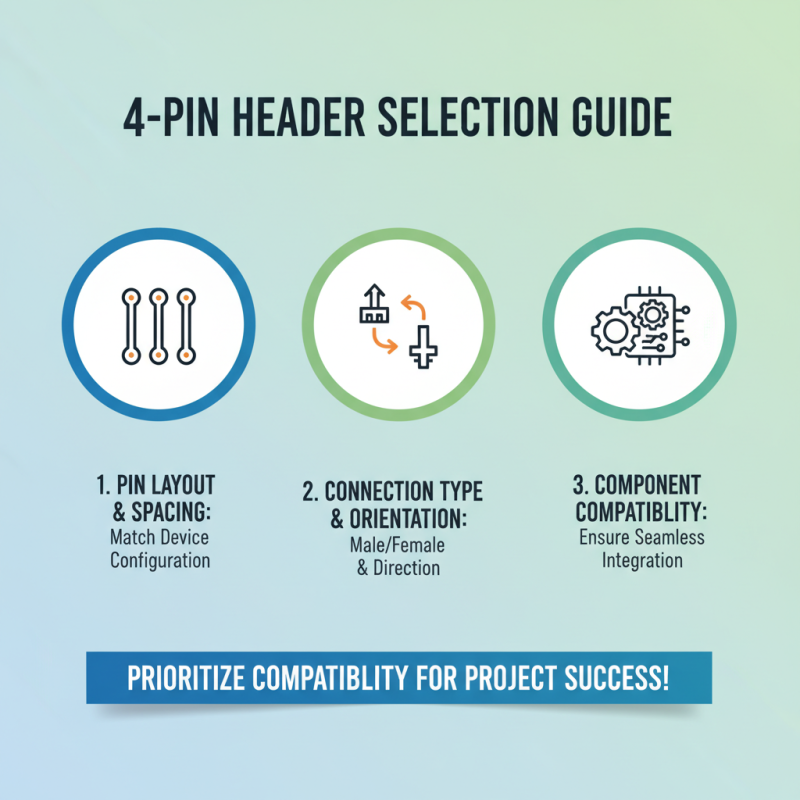

When selecting a 4 pin header socket for your project, ensuring compatibility with other components is of utmost importance. First, it's crucial to consider the pin layout and spacing. Different components may have varying configurations, so verifying that the header socket matches the pin arrangement of your devices can prevent connectivity issues. Moreover, the type of connection—whether male or female headers, and the orientation—also plays a significant role in ensuring a seamless integration into your project.

Tips: Always double-check the specifications of all the components involved in your project. This extra step can save time and frustration during assembly. If you're sourcing parts from multiple suppliers, confirm that they adhere to the same specifications to avoid discrepancies that may lead to malfunction.

Additionally, pay attention to the electrical ratings of the header socket. Different applications may require specific voltage and current ratings, so matching these ratings across your components is critical to ensure reliable performance. Inspect the materials used for the header socket as well; those made from durable materials can withstand thermal and mechanical stress, promoting longevity in your projects.

Tips: Consider using a multimeter to test connectivity before final assembly. This can help identify any compatibility issues early on, allowing you to make adjustments without significant delays. Engaging in meticulous planning and testing can enhance your project's success and efficiency.

When selecting the right 4-pin header socket for your project, it's essential to consider a few key factors that will ensure compatibility and functionality. First and foremost, evaluate the pin spacing and layout requirements. Pin spacing can vary, so matching it to your existing components is crucial. Additionally, consider whether you need a socket with locking features or one that allows for easy insertion and removal of pins. This can significantly impact the usability of your project and prevent accidental disconnections.

Another important aspect to weigh is the current and voltage ratings of the header socket. Different projects will have varying power requirements, so it's vital to choose a socket that can handle the intended load without overheating or failing. Material quality is also a consideration; opt for sockets with durable contacts and housing to ensure long-term reliability in various environments. Additionally, think about factors like temperature ranges and resistance to environmental factors such as dust or moisture, as these can further influence the performance and longevity of the header socket in your application. By carefully considering these factors, you can make a well-informed decision that enhances your project's overall effectiveness.