The function and principle of a floating connector

What is a floating connector?

Floating connectors, also known as floating ball supports, are important components for connecting pipelines and equipment. They are typically made by winding inner and outer layers of steel wire into a spiral shape. The inner layer of steel wire compensates for pipeline displacement, while the outer layer serves to secure it. Floating connectors can alleviate deformation in both horizontal and vertical directions during pipeline operation, preventing damage caused by deformation due to self-weight or temperature changes. They also reduce vibrations and noise transmitted from the pipeline to buildings.

The function of a floating connector

1. Shock Absorption and Vibration Reduction

Floating connectors can withstand displacements in different directions generated by pipelines during operation, preventing the pipeline from vibrating. It can serve as a shock absorber when the pipeline is subjected to earthquakes, noise, fluid impact, and other environmental stresses.

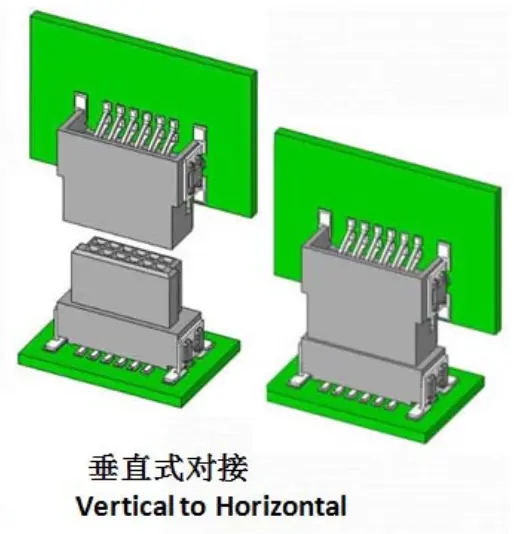

2. Direction and Displacement Adjustment

Floating connectors can adjust the direction and displacement of pipelines, enabling them to adapt to various complex deformation scenarios. This allows the pipeline to withstand various pressures without sustaining damage.

The principle of the floating connector

The principle of the floating connector is to use elastic deformation to achieve pipeline displacement compensation and vibration reduction. The elastic characteristics of materials such as steel wire ropes and rubber can effectively accomplish this function. During the operation of the pipeline, forces in different directions are distributed to the steel wire ropes and rubber pads of the floating ball support. The steel wire rope can cause the floating ball support to undergo elastic deformation, offsetting the forces generated by pipeline deformation and other factors, thereby balancing the pipeline.

The application of floating connectors

Floating connectors are widely used in various industrial production fields, such as petrochemicals, pharmaceuticals, food, steel, water treatment, etc. They can handle different pipeline transmission media and temperature changes. At the same time, the structure of floating connectors is becoming increasingly sophisticated to meet the needs of pipeline operation. In short, the role of floating connectors is not only to connect pipelines but also to provide shock absorption, vibration reduction, and adjustment of pipeline direction and displacement. Their use not only ensures the safe operation of pipelines but also improves the efficiency of industrial production.