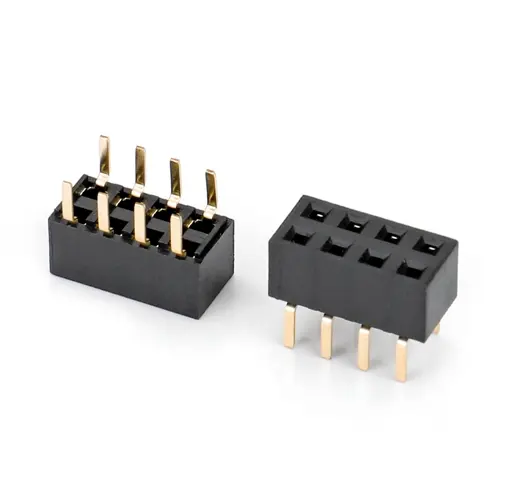

The Four Processes of Connectors

Many people feel that there are too many types of electroniC Connectors, and the manufacturing process should be different. In fact, the manufacturing process of the connector is basically the same, which can be divided into stamping (connectors are used in many places in life, such as automobiles, computers and other electronic equipment are essential choices for connectors. Many people feel that there are too many types of electronic connectors, and the manufacturing process should be different. In fact, the manufacturing process of the connector is basically the same, which can be divided into four manufacturing processes: Stamping, Plating, injection and Assembly.

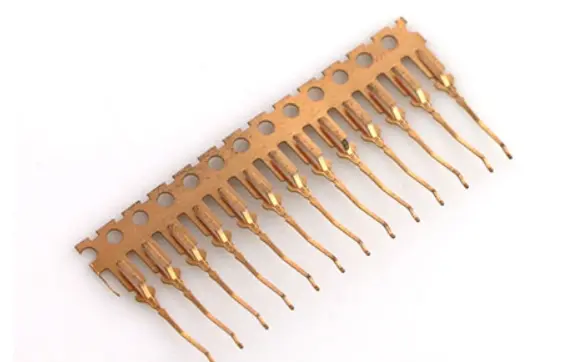

1. Stamping: Stamping is made by a large high-speed punching machine, so that the electronic connector (pin) is stamped by a thin metal strip. One end of the large roll metal belt is fed into the front end of the punching machine, and the other end is wrapped into the coil pulley through the hydraulic table of the punching machine, and the metal belt is pulled out by the coil pulley and the finished terminal is rolled.

2. Plating: The connector pin should be sent to the plating stage after stamping. In the plating stage, the electronic contact surface of the connector will be plated with various metal coatings, nickel plating, tin plating, and semi-gold plating to prevent oxidation and strengthen electrical conductivity. The pins will also be twisted, cracked or deformed during the process of feeding the stamped pins into the plating equipment. These quality defects are easily detected by the above techniques.

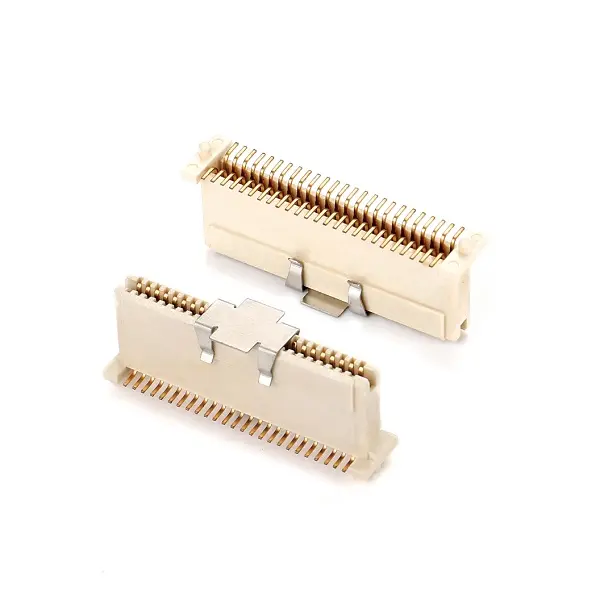

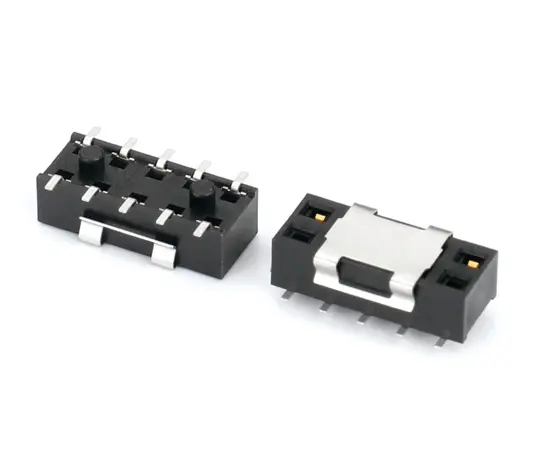

3.Injection: Injection molding refers to the plastic box seat of the electronic connector by injecting melted plastic into the metal tire film, and then quickly cooling to form. Also pay attention to detect whether there is a "leak" when the molten plastic fails to fully fill the fetal membrane; (Short Shots), which is a typical defect that needs to be detected during the injection molding phase. Other defects include the filling or partial blockage of connector jacks (which must be kept clean and unblocked so that pins can be inserted correctly during final assembly).

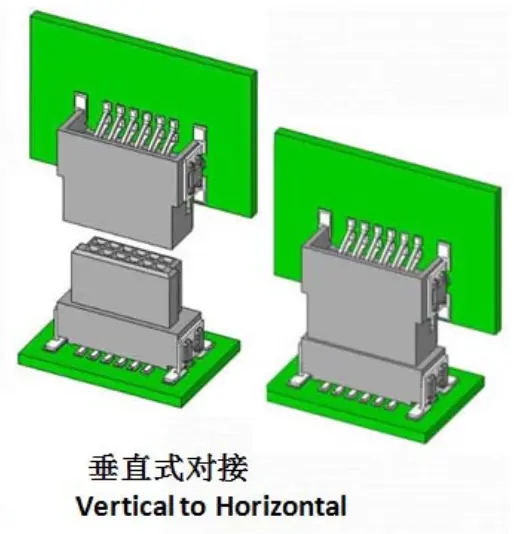

4. Assembly: Assembly The final stage of the manufacture of electronic connectors is the assembly of the finished product. There are two ways to assemble the electroplated pin and the injection box socket: the first is to insert separately, which means to insert a pin each time; The second is the combination of combination and insertion, which means that multiple pins are inserted with the box seat at the same time. No matter what kind of insertion method is used to assemble, it is necessary to ensure that all pins do not have any gaps and positioning must be correct. In addition to ensuring the quality of the product, pay attention to safety in the manufacturing process of the connector.