How to select suitable board-to-board connectors

So when choosing the connector, from what point of view should we consider the connector suitable for hardware use?

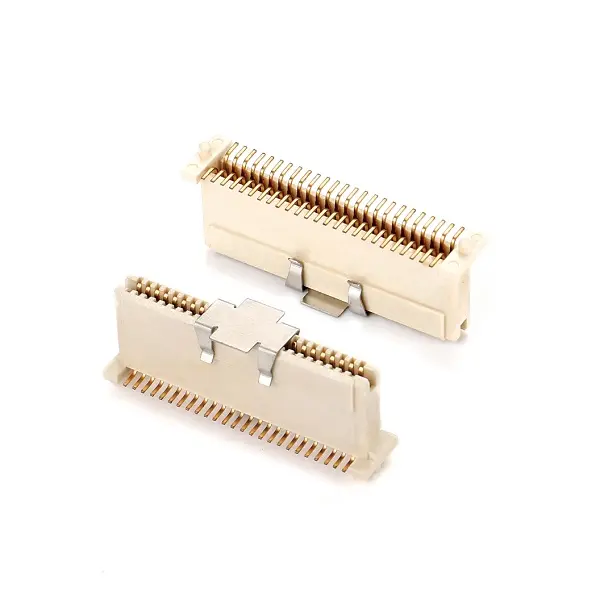

1. Pins, Pitch

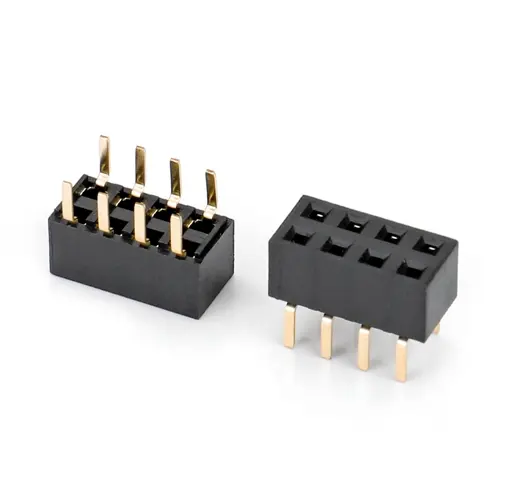

Pin number and pin spacing are the basic basis for connector selection. How many pin numbers of connectors you choose depends on the number of signals that need to be connected. For some patch connectors, the patch row pin shown in the following figure should not be too many pins. Because in the welding process of the SMT machine, due to high temperature, the connector plastic will be heated and deformed, and the middle bulge will cause virtual welding of the pin. In the early stage of development of our P800Flash programmer, we used this kind of pin and bar to make inter-board connection, and the result was that the pin of the prototype pin was welded in a large area. After replacing the two pins with half the number of pins, there was no false welding.

Nowadays, electronic devices are developing towards miniaturization and precision, and the pin spacing of connectors is also from 2.54mm to 1.27mm to 0.5mm. The smaller the pin spacing, the higher the production process requirements. The pin spacing should be determined by the company's production process level, and the blind pursuit of small spacing

2. Electrical performance

The electrical performance of the connector mainly includes: limit current, contact resistance, insulation resistance and electrical strength. When connecting a high-power power supply, pay attention to the limit current of the connector; When transmitting high-frequency signals such as LVDS and PCIe signals, pay attention to the contact resistance. The connector should have a low and constant contact resistance, generally tens of mΩ to hundreds of mΩ.

3. Environmental performance

The environmental performance of the connector mainly includes: temperature resistance, humidity resistance, salt spray resistance, vibration, impact and so on. Select according to the specific application environment. If the application environment is humid, the connector's moisture resistance and salt spray resistance are required to avoid corrosion of the metal contacts of the connector. In the field of industrial control, the vibration impact resistance of the connector is required to be high, so as to avoid the connector falling off during vibration.

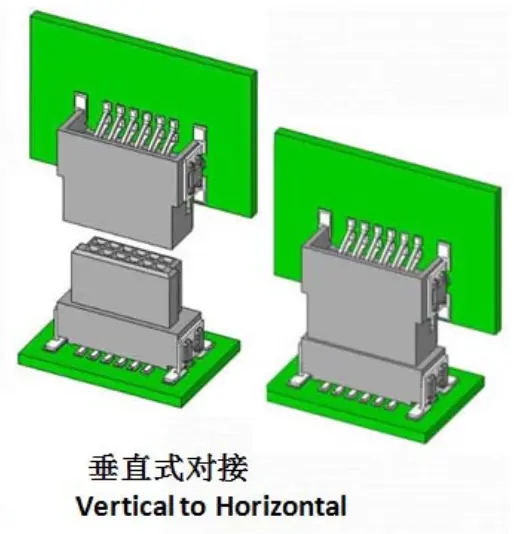

4. Mechanical properties

The mechanical properties of the connector include plugging force, mechanical anti-stay, etc. Mechanical anti-stay is very important to the connector, once inserted, it is likely to cause irreversible damage to the circuit!

The insertion force is divided into insertion force and separation force. There are provisions in the relevant standards for greater insertion force and minimum separation force, from the point of view of use, the insertion force should be small, the separation force should be large. Too little separation force will reduce the reliability of contact, but for connectors that often need to be plugged and unplugged, too much separation force will increase the difficulty of pulling out and reduce the mechanical life.