Environmental protection and sustainable development of connector components

Environmental issues in the manufacture and use of connector components

The manufacturing of connector components involves metal smelting, plastic processing and other links, these processes not only consume a lot of energy, but also produce waste water, waste gas, solid waste and other pollutants. In addition, traditional connector components often contain harmful substances such as lead and halogens, which may cause harm to human health and the environment during manufacturing, use and disposal. With the acceleration of the replacement of electronic products, the amount of waste connector components has also increased sharply, bringing great pressure to the environment.

The impact of environmental protection and sustainable development on the connector component industry

The in-depth concept of environmental protection and sustainable development has prompted the connector component industry to change the development mode, reduce environmental pollution from the source, and improve resource utilization efficiency. This is not only a response to the call of global environmental protection, but also an inevitable choice for the survival and development of enterprises themselves. Environmental protection and sustainable development require the connector component industry to carry out comprehensive innovation in material selection, manufacturing process, product design, recycling and other aspects to adapt to increasingly stringent environmental regulations and market demand.

Environmentally friendly materials for connector components

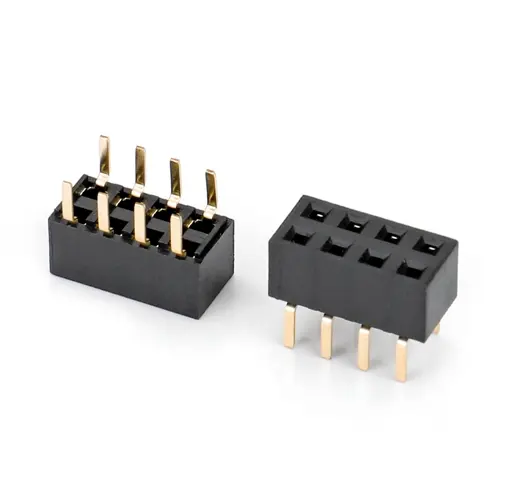

Lead-free, halogen-free materials: The lead-tin alloys commonly used in traditional connector components contain the heavy metal lead, which poses a threat to the environment and human health. Lead-free materials such as tin silver copper alloy have gradually become the mainstream, while halogen-free materials can effectively reduce the toxic gas generated during combustion and improve product safety.

Biodegradable materials: Biodegradable materials are materials that can be decomposed by microorganisms in the natural environment, and have the potential to reduce environmental pollution and reduce the accumulation of plastic waste. In the connector components, the application of biodegradable materials is still in the exploration stage, but it has broad prospects in the development of future environmentally friendly connectors.

Recyclable materials: The selection of materials that are easy to recycle, such as high-purity metals, high-performance plastics, etc., can not only reduce the waste of resources, but also reduce the environmental cost of connector component waste treatment.

Green manufacturing process for connector components

Energy-saving manufacturing process: By optimizing the production process, improving the energy efficiency of the equipment, using clean energy and other measures to reduce the energy consumption in the manufacturing process of connector components.

Waste reduction and recycling: Implement strict waste management in the manufacturing process, reduce waste emissions through classified collection, comprehensive utilization and other ways to achieve the maximum utilization of resources.

Clean production technology: The use of advanced clean production technology, such as wastewater treatment, waste gas purification, solid waste recycling, etc., to ensure that the negative impact of the production process on the environment is minimized.

Recovery and reuse of connector components

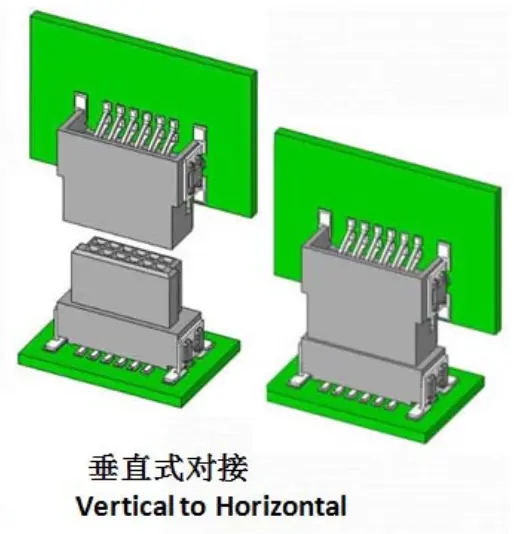

Recovery technology and process: The recovery of connector components involves disassembly, classification, separation, purification and other links. With the development of technology, efficient recycling technologies such as physical separation and chemical recycling are gradually applied to the recycling of connector components.

Reuse pathways and case studies: The recovered connector component materials can be purified and reused for connector manufacturing, as well as other industrial raw materials. For example, recycled metals can be used to produce new electronic components, and recycled plastics can be used to make other plastic products.

Economic and environmental benefits of recycling: The recycling of connector components not only helps to reduce resource consumption and environmental pollution, but also brings economic benefits to enterprises. Through recycling, enterprises can reduce raw material procurement costs, improve resource utilization efficiency, and reduce waste disposal costs.

Environmental regulations and standards for the connector component industry

Overview of international environmental regulations: With the increasing awareness of global environmental protection, countries have introduced a series of environmental regulations, such as the European Union's RoHS directive (restriction of the use of certain hazardous substances Directive), WEEE Directive (Waste electrical and Electronic Equipment Directive), etc., which put forward strict requirements for the manufacture and use of connector components.

Environmental standards and certification of connector components: In order to meet the requirements of environmental regulations, the connector components industry has developed a series of environmental standards, such as the environmental certification of UL (American Underwriters Testing Institute) and the environmental standards of IEC (International Electrotechnical Commission). These standards and certifications provide authoritative assurance of the environmental performance of connector components.

Conclusion:

Environmental protection and sustainable development have posed serious challenges to the connector component industry, but also pregnant with unlimited opportunities. Through the use of environmentally friendly materials, green manufacturing processes, recycling and other measures, the connector component industry can achieve industrial upgrading and sustainable development while protecting the environment. In the future, the connector component industry should continue to strengthen the research and development of environmental protection technology, improve the level of environmental protection standards and certification, actively participate in international environmental protection cooperation and exchanges, and jointly promote the green development of the global electronics industry.