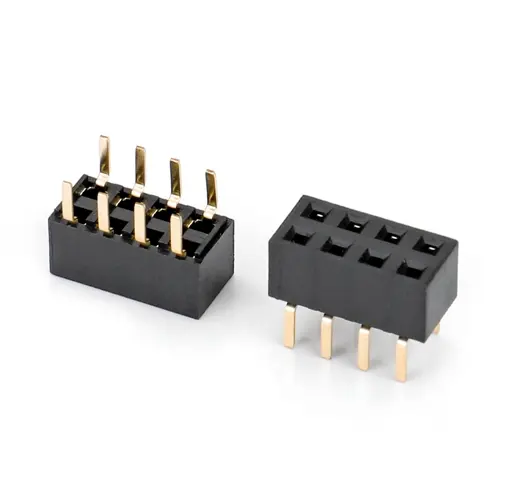

Comparison of characteristics and application of bright tin and mist tin in tin plating

1. Comparison of characteristics of bright tin and mist tin

1)Characteristics of bright tin

Advantages: Bright tin plating because of the addition of gloss agent in the plating solution, making the crystallization process more detailed. This fine crystalline structure helps to improve the gloss and beauty of the surface. With good gloss and reflectivity, it is not easy to leave fingerprints. And the price has a certain advantage.

Disadvantages: The use of bright tin light agent, the metal contains more organic matter leading to poor weldability, poor welding performance means that it is easy to produce tin whiskers at high temperatures, will form a short circuit between conductors, affecting electrical performance. At the same time, the high temperature resistance is poor, easy to change color at high temperature.

Disadvantages: The coating surface is matte or fog effect, low gloss, relatively rough crystallization, easy to leave fingerprints, but also afraid of scratches, weldability is good, the cost is relatively high.

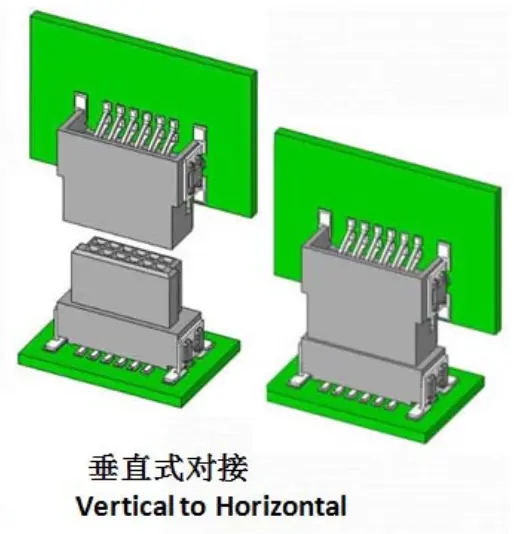

2. Generalized application scenario comparison

The surface of the mist tin is matte or mist effect, and there is no gloss like that of the bright tin. This coating is often used in applications that require reduced reflection or improved adhesion, such as parts in optical instruments, or decorative parts that require low gloss.

In summary, the choice of tinning process depends on the specific application requirements, such as aesthetics, electrical conductivity, weldability and the need to reduce surface reflection. When selecting the tinning process, the performance requirements and use environment of the final product should also be considered.