In the ever-evolving landscape of electronic design, the significance of selecting the right components cannot be overstated. Among these, the Pin Header Socket plays a crucial role in ensuring seamless connectivity and reliability in various applications. According to a recent report by MarketsandMarkets, the global connector market is poised to reach $83.4 billion by 2026, with a significant portion attributed to the increasing demand for efficient connections in consumer electronics and automotive industries. As projects become more complex, the need for robust and versatile pin header sockets grows, making it essential for engineers and hobbyists alike to understand the multitude of options available. This guide aims to provide valuable insights into choosing the best pin header socket to meet your project needs, taking into account factors like design specifications, operational requirements, and future scalability.

When it comes to electronic projects, selecting the right pin header socket is crucial for ensuring reliable connections and seamless functionality. Pin header sockets, commonly used in PCB design, come in various configurations, sizes, and materials, which can significantly impact the performance of your project. According to a recent industry report by Grand View Research, the global demand for connectors, including pin header sockets, is expected to reach USD 100 billion by 2028, highlighting their importance in the electronics marketplace.

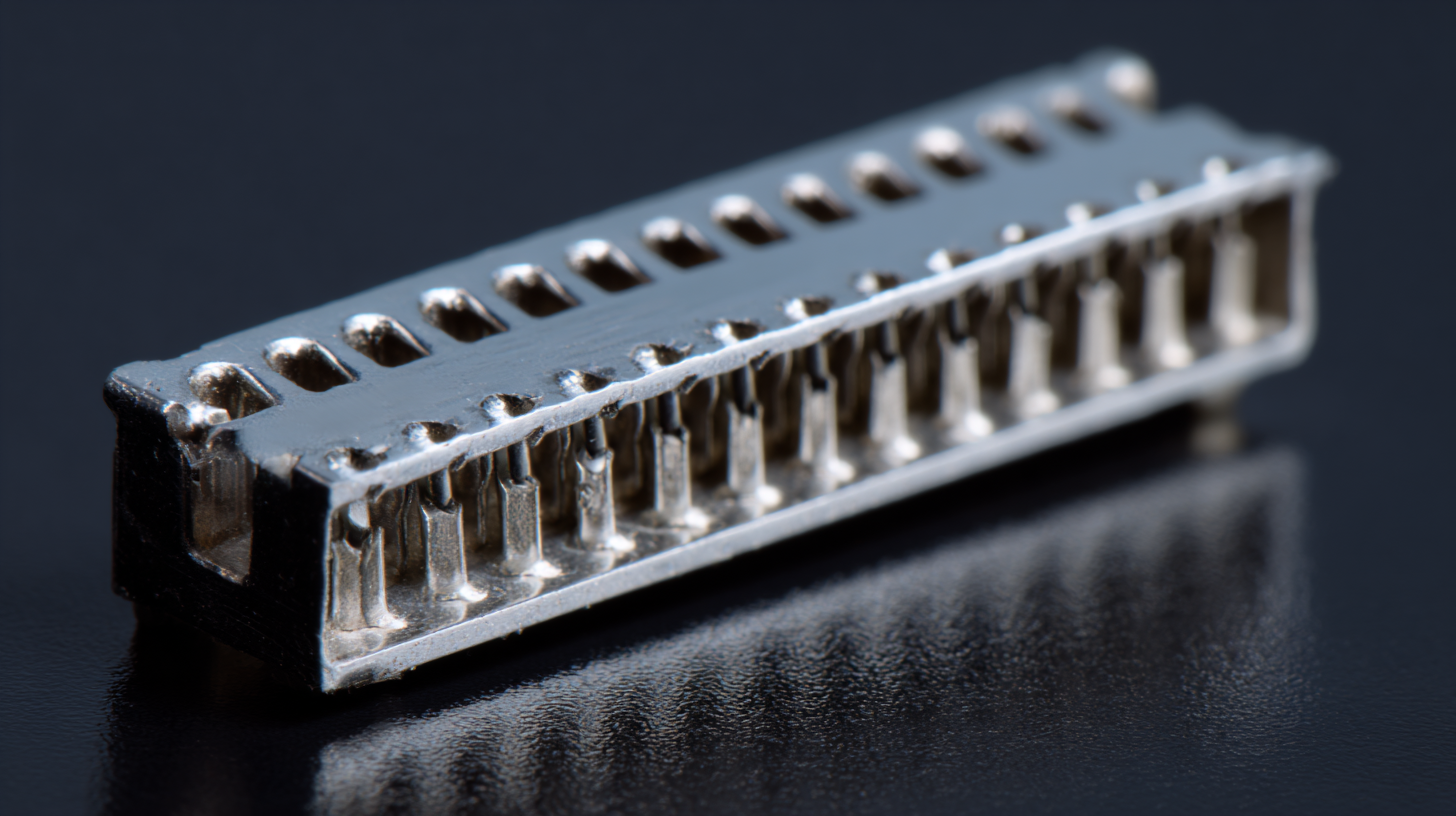

Understanding the fundamentals of pin header sockets can greatly enhance your design efficiency. Consider factors such as pin count, pitch, and mounting style. For example, a standard 2.54mm pitch is widely used in various applications, from simple breadboards to complex circuit boards. Choosing a high-quality socket made from durable materials like polyamide can also prevent issues such as thermal expansion and corrosion, ensuring longevity.

Tip: Always verify compatibility with your PCB layout before purchasing a pin header socket. Another essential tip is to check the rated current and voltage of the socket to ensure it meets the requirements of your specific project. Proper attention to these details can save time and resources in the long run.

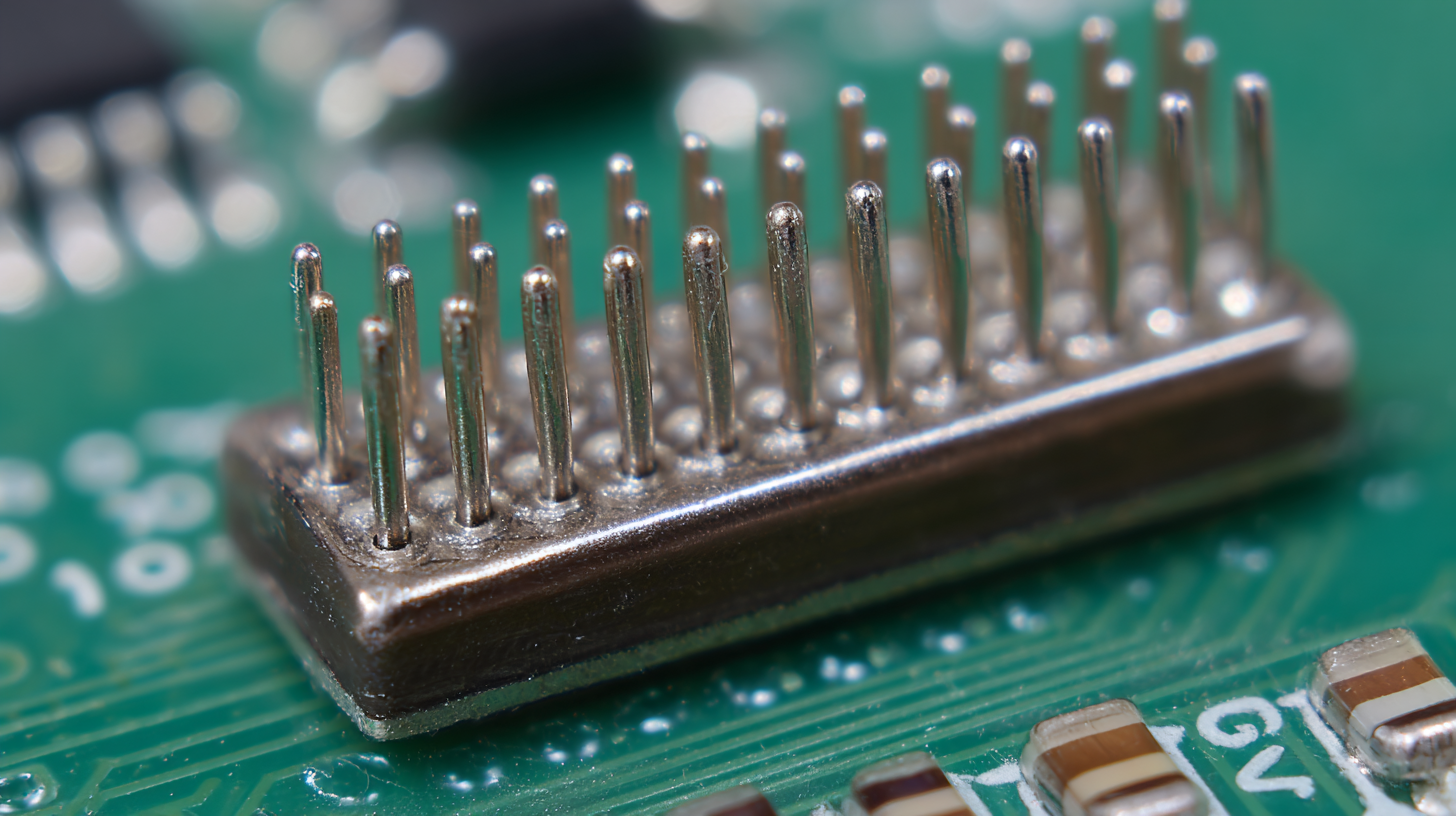

When selecting the best pin header socket for your project, there are several key features to consider that can greatly impact the functionality and reliability of your connections. First and foremost, it's essential to assess the pitch size of the pin header sockets. Commonly found in 2.54mm and 1.27mm configurations, the pitch size determines compatibility with your circuit board and the density of the pins, affecting both space and soldering ease.

Another critical feature to examine is the material composition of the sockets. High-quality sockets typically utilize gold or tin plating, which can influence conductivity and resistance to oxidation, ensuring long-term performance. Additionally, the socket's voltage and current ratings should align with your project's specifications to prevent overheating or failure. A solid built with plastic housing that withstands high temperatures is also crucial, especially in demanding environments. By paying attention to these factors, you can ensure that you select pin header sockets that meet your project needs effectively.

This chart illustrates key features to consider when selecting pin header sockets for various project needs, including circuit type, pin count, pitch, operating temperature, and current rating. Each parameter reflects the critical attributes that engineers and designers evaluate during the selection process.

As we step into 2025, the landscape of pin header technology is evolving rapidly, reflecting broader trends in electronics and connectors. According to the Asia Pacific Connector Market Size & Share Report, the connector market is expected to grow at a compound annual growth rate (CAGR) of 4.1% from 2025 to 2034, highlighting the increasing demand for advanced connectivity solutions across various sectors. This surge is particularly driven by the expansion of data center infrastructure and the proliferation of high-speed data applications, emphasizing the need for robust and reliable pin header sockets in modern electronic designs.

In addition to market growth, technological innovations are shaping the future of pin headers. The introduction of co-packaged optics technology is demonstrating that the evolution of connector designs is essential to meet the staggering capacity demands, which have increased from 0.64 Tbps to 25.6 Tbps in data center switches over the past decade. This advancement not only emphasizes the importance of pin headers in facilitating high-speed connections but also places a spotlight on thermal management solutions, as overheating connectors can lead to critical failures in high-performance environments. As projects become more sophisticated, selecting the right pin header socket becomes not just a matter of compatibility but also one of ensuring optimal performance and longevity.

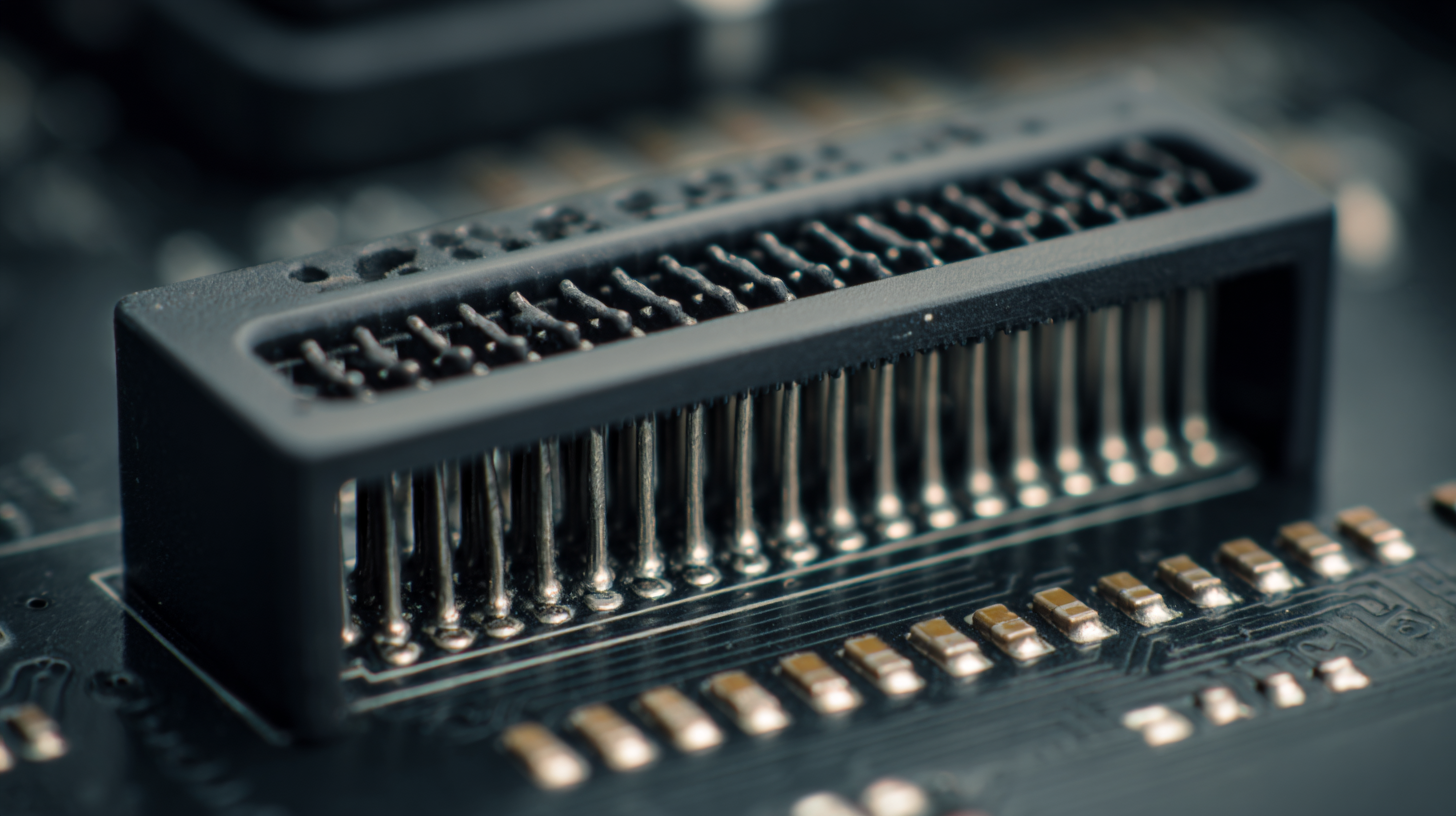

When embarking on a project that requires pin header sockets, the first step is to comprehensively analyze your specific requirements. Consider the electrical specifications, such as voltage and current ratings, which are crucial for ensuring compatibility with your circuit. Additionally, assess the physical dimensions and layout of your board; this involves understanding the spacing between headers and the overall footprint. A mismatch in any of these areas could lead to functionality issues, so it's essential to document these critical parameters early in the planning stage.

Furthermore, think about the intended use of the sockets in your project, as this will influence your selection significantly. Are you looking for a permanent solution or a more flexible, modular approach? For example, if your project will undergo frequent modifications, opt for sockets that facilitate easy connection and disconnection. Durability should also be a priority; consider materials that can withstand the environmental conditions they will face, such as temperature fluctuations or exposure to moisture. Prioritizing these factors will guide you in selecting the optimal pin header socket tailored to your project's unique needs.

When integrating pin header sockets into electronic designs, adherence to best practices is essential to ensure reliability and functionality. According to a recent report from the Electronics Component Industry Association (ECIA), approximately 30% of electronic design failures can be attributed to improper connections and component selection. To mitigate these risks, designers should prioritize using high-quality sockets that meet industry standards such as IEC 60664 for insulation and mechanical properties. This ensures optimal performance in various environmental conditions.

Another critical aspect is the selection of the appropriate pin configuration. A study by MarketsandMarkets indicates that the demand for customizable pin header sockets is projected to grow by 15% annually owing to the increasing need for tailored electronic solutions in sectors like automotive and consumer electronics. Designers should take into account factors such as pitch size and number of pins based on the specific requirements of their projects. Proper planning and integration not only enhance performance but also reduce the potential for signal integrity issues, leading to more robust designs.

| Pin Header Type | Number of Pins | Pitch (mm) | Current Rating (A) | Operating Temperature (°C) | Mounting Style |

|---|---|---|---|---|---|

| Standard Pin Header | 40 | 2.54 | 3 | -40 to +85 | Through-Hole |

| Low Profile Pin Header | 20 | 2.54 | 2 | -40 to +105 | Surface Mount |

| Double Row Pin Header | 16 | 2.00 | 2 | -40 to +85 | Through-Hole |

| Extended Pin Header | 10 | 2.54 | 1.5 | -40 to +100 | Surface Mount |