The demand for reliable and efficient connectivity in industrial applications is increasingly vital as industries evolve towards automation and smart technologies. According to a recent report by MarketsandMarkets, the industrial connectors market is projected to reach USD 5.5 billion by 2025, growing at a CAGR of 8.2% from 2020. This growth is driven by the burgeoning need for seamless communication and power distribution across various sectors, including oil and gas, aerospace, and manufacturing.

Experts in the field recognize the significance of selecting the right Industrial Connector for specific applications. John Smith, a leading expert in industrial connectivity and author of the "Industrial Connectivity Trends" report, emphasized, "The choice of industrial connectors can significantly influence the performance and reliability of automation systems." As industries become increasingly interconnected, the integration of robust connectors not only ensures the smooth operation of machinery and equipment but also enhances safety and operational efficiency.

This article will delve into the key features, various applications, and essential considerations when purchasing industrial connectors, providing valuable insights for industry professionals seeking to optimize their connectivity solutions.

Industrial connectors are critical components in various industries, serving as the bridge between different electrical and electronic systems. Defined as devices that join two or more electrical circuits, these connectors are vital for ensuring reliable power and signal transmission across machinery and equipment. Their importance lies in their ability to facilitate seamless communication and coordination within complex systems, which is essential for operational efficiency and safety.

The role of industrial connectors extends beyond mere connectivity; they are designed to withstand harsh environmental conditions, such as extreme temperatures, moisture, and vibrations. This durability is crucial in manufacturing plants, automotive applications, and outdoor installations where reliability is paramount. Additionally, the variety of connector types available, such as circular connectors, rectangular connectors, and panel mount options, allows for tailored solutions that meet specific industry demands. Understanding the definition and importance of industrial connectors provides a solid foundation for selecting the right components for diverse applications, ultimately contributing to enhanced system performance and longevity.

When selecting industrial connectors, several key features should be prioritized to ensure optimal performance and reliability. Firstly, the material of the connector is crucial; robust materials such as high-grade plastic or metal greatly enhance durability and resistance to environmental factors like moisture and dust. Additionally, the connector's ingress protection (IP) rating can indicate its level of resistance against dust and water, making it essential for applications in harsh conditions.

Another significant feature is the connector's current and voltage rating, which must align with the specifications of the equipment being used. It's important to choose connectors that can handle the required electrical load without overheating or degrading over time. Furthermore, compatibility and ease of assembly are vital considerations; connectors that are user-friendly and versatile can significantly streamline the installation process and reduce maintenance time. Lastly, certifications and standards compliance, such as UL and IEC, ensure that the connectors meet industry regulations for safety and performance.

Industrial connectors play a crucial role in various sectors, facilitating seamless communication between electronic devices and equipment. One of the most prominent applications of industrial connectors is in the manufacturing sector, where they are essential for connecting machines and sensors. According to a report by MarketsandMarkets, the industrial connectors market is projected to reach USD 5.89 billion by 2024, driven largely by the rising automation in manufacturing processes. These connectors ensure reliable power supply and data transfer, reducing downtime and enhancing operational efficiency.

Another key application can be found in the transportation industry, particularly in rail and automotive systems. Industrial connectors are vital for vehicle-to-everything (V2X) communication, which is essential for the advancement of smart transportation solutions. A report from Research and Markets indicates that the global market for automotive connectors is expected to grow at a CAGR of 8% from 2021 to 2026, highlighting the increasing reliance on robust connector systems to support the complex electrical architectures of modern vehicles. This trend underscores the importance of industrial connectors in promoting safety and efficiency in transportation networks.

| Connector Type | Key Features | Applications | Industry |

|---|---|---|---|

| Circular Connectors | Durable, Waterproof, Easy to Install | Robotics, Automotive | Manufacturing, Automotive |

| Rectangular Connectors | High Density, Versatile, Customizable | PCB Connections, Telecommunications | Telecom, Electronics |

| Modular Connectors | Flexible, Plug-and-Play, Space Saving | Data Transmission, Networking | IT, Telecommunications |

| Fiber Optic Connectors | High Speed, Low Loss, Secure | Internet Services, Data Centers | IT, Telecommunications |

| Power Connectors | High Current Rating, Reliable Performance | Industrial Machinery, Electric Vehicles | Manufacturing, Automotive |

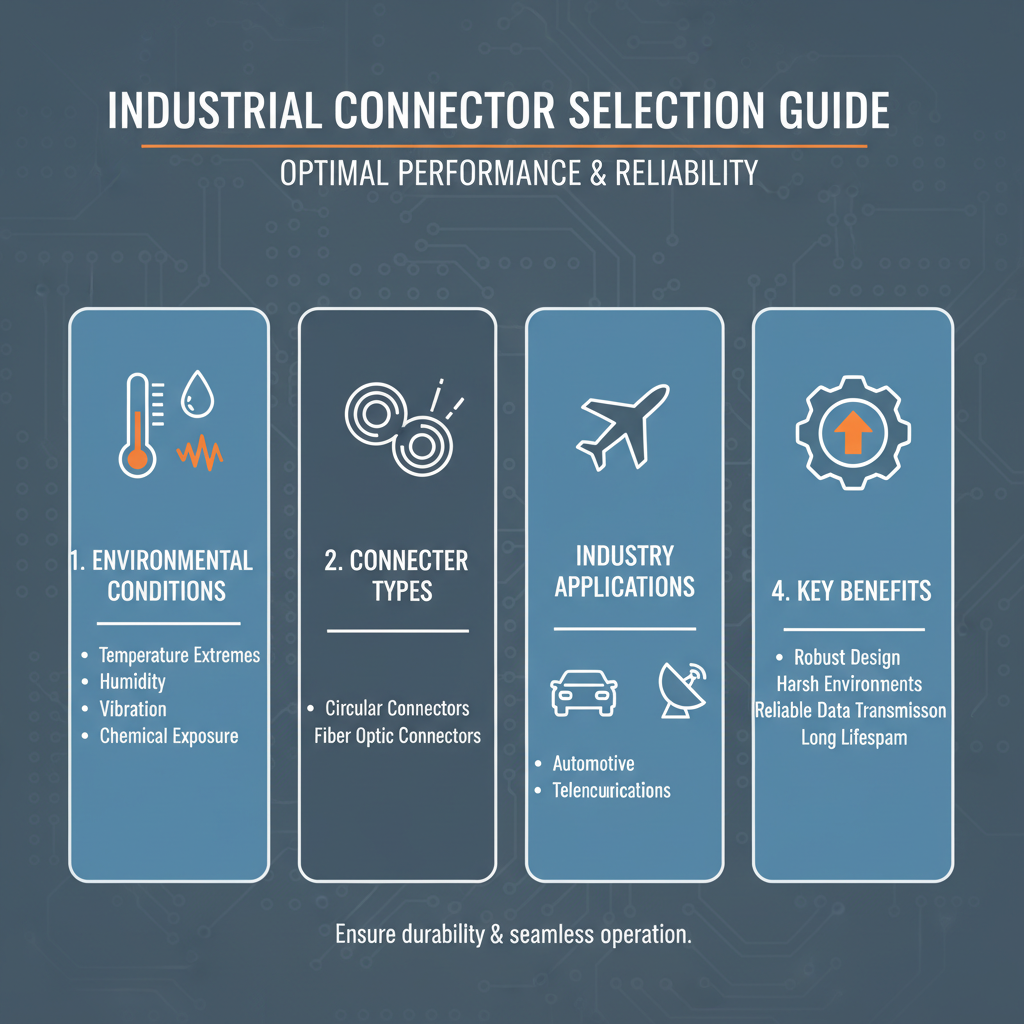

When selecting industrial connectors, several crucial factors must be taken into account to ensure optimal performance and reliability. Key considerations include the environmental conditions in which the connectors will operate, such as temperature extremes, humidity, vibration, and exposure to chemicals. Connectors designed for harsh environments, such as circular connectors and fiber optic connectors, are ideal for applications in industries like aerospace, automotive, and telecommunications.

According to recent industry analyses, the global connector market is projected to reach substantial growth, driven by increasing demands in various sectors, including automotive, industrial machinery, and consumer electronics. PCB connectors and I/O connectors are anticipated to see significant market share due to their widespread use in electronic devices. It's essential to choose connectors that not only meet technical specifications but also align with the intended application to maximize efficiency and minimize downtime. Careful evaluation of these factors will guide buyers in making informed decisions in a rapidly evolving market landscape.

When it comes to the longevity and reliability of industrial connectors, proper maintenance and adherence to best practices are crucial. According to a report from the International Electrotechnical Commission (IEC), approximately 30% of industrial connector failures stem from neglecting regular maintenance. Routine inspections to identify wear and corrosion can significantly mitigate these risks. The use of contact cleaners and specialized lubricants can ensure that the connectors remain free from contaminants that may cause poor connectivity or short circuits.

Additionally, understanding the specific operating environment is paramount. For instance, connectors used in heavy machinery exposed to vibration may require more frequent checks, as the mechanical stress can lead to connection loosening over time. The National Electrical Manufacturers Association (NEMA) suggests implementing a predictive maintenance schedule based on operational data, which can enhance the connector's performance lifespan by up to 20%. By investing in training for personnel on proper handling and installation techniques, industries can further minimize the likelihood of connector failures and optimize operational efficiency.