In the rapidly evolving landscape of electronic connectivity, Pin Header Sockets have emerged as crucial components, bridging the gap between various devices and ensuring seamless communication. According to recent industry reports, the global market for interconnect solutions is projected to reach $80 billion by 2025, driven by the burgeoning demand for advanced connectivity in smart devices and IoT applications. As manufacturers increasingly prioritize miniaturization and performance, the innovation within Pin Header Socket technologies is set to revolutionize how we connect and interact with our electronics. This blog will delve into the top 10 best Pin Header Sockets that are shaping the future of connectivity, highlighting their unique features and the significant role they play in the advancement of electronic systems.

The evolution of pin header sockets has taken a significant turn as we approach 2025, marked by groundbreaking innovations that enhance connectivity across various applications. Traditionally, pin header sockets have been crucial in electronics, providing reliable connections for circuit boards in everything from consumer gadgets to industrial machinery. However, recent market analysis indicates a 14% growth in demand for advanced pin header solutions due to their increasing integration in IoT devices and smart systems (Source: Industry Research Report 2023). This shift underscores the necessity for manufacturers to embrace next-gen designs that cater to higher data rates and improved signal integrity.

To stay ahead in this competitive landscape, engineers should prioritize key features in pin header sockets, such as modularity and reduced footprint. For instance, tips such as utilizing polarized designs can not only simplify assembly but also prevent wiring mistakes, contributing to overall device reliability. Furthermore, adopting materials that enhance thermal performance can lead to longevity in harsh operating environments. As technology rapidly evolves, investing in innovative pin header sockets will ensure seamless connectivity and significantly reduce the risk of downtime.

Moreover, insights from the latest technical reports reveal that customization is becoming increasingly important. Companies that offer tailored solutions are likely to capture a larger share of the market. To thrive, it's essential to understand client needs and deliver pin header sockets that meet or exceed industry standards, thereby revolutionizing connectivity for the next generation of electronic devices.

In the rapidly evolving landscape of technology, the quality of components like pin header sockets plays a crucial role in ensuring reliable connectivity. Chinese manufacturing has emerged as a cornerstone of this industry, consistently setting global standards with its rigorous quality control processes and advanced production techniques. With a blend of traditional craftsmanship and cutting-edge automation, Chinese manufacturers are able to produce pin header sockets that not only meet but often exceed international performance benchmarks.

The commitment to quality is evident in the materials used and the testing protocols implemented. Manufacturers in China employ a variety of stringent quality assurance practices to ensure that every socket is built to withstand the demands of modern electronic applications. This dedication to excellence has prompted many global tech companies to source components from Chinese suppliers, recognizing the value of high-performance products that can enhance the overall reliability of their innovations. As the industry moves towards higher connectivity standards, the influence of Chinese manufacturing continues to expand, revolutionizing the way we think about electronic components.

This chart illustrates the performance and quality ratings of the top 10 pin header sockets, showcasing how their designs and functionalities are setting new standards in global connectivity solutions.

In the rapidly evolving landscape of electronic connectivity, selecting the right pin header socket is crucial for enhancing performance and reliability. According to a recent market analysis by Allied Market Research, the global market for connector components is projected to reach $40 billion by 2027, driven by the increasing demand for efficient data transmission across various industries. Pin header sockets, integral to these connectors, serve as vital interfaces in applications ranging from consumer electronics to industrial automation.

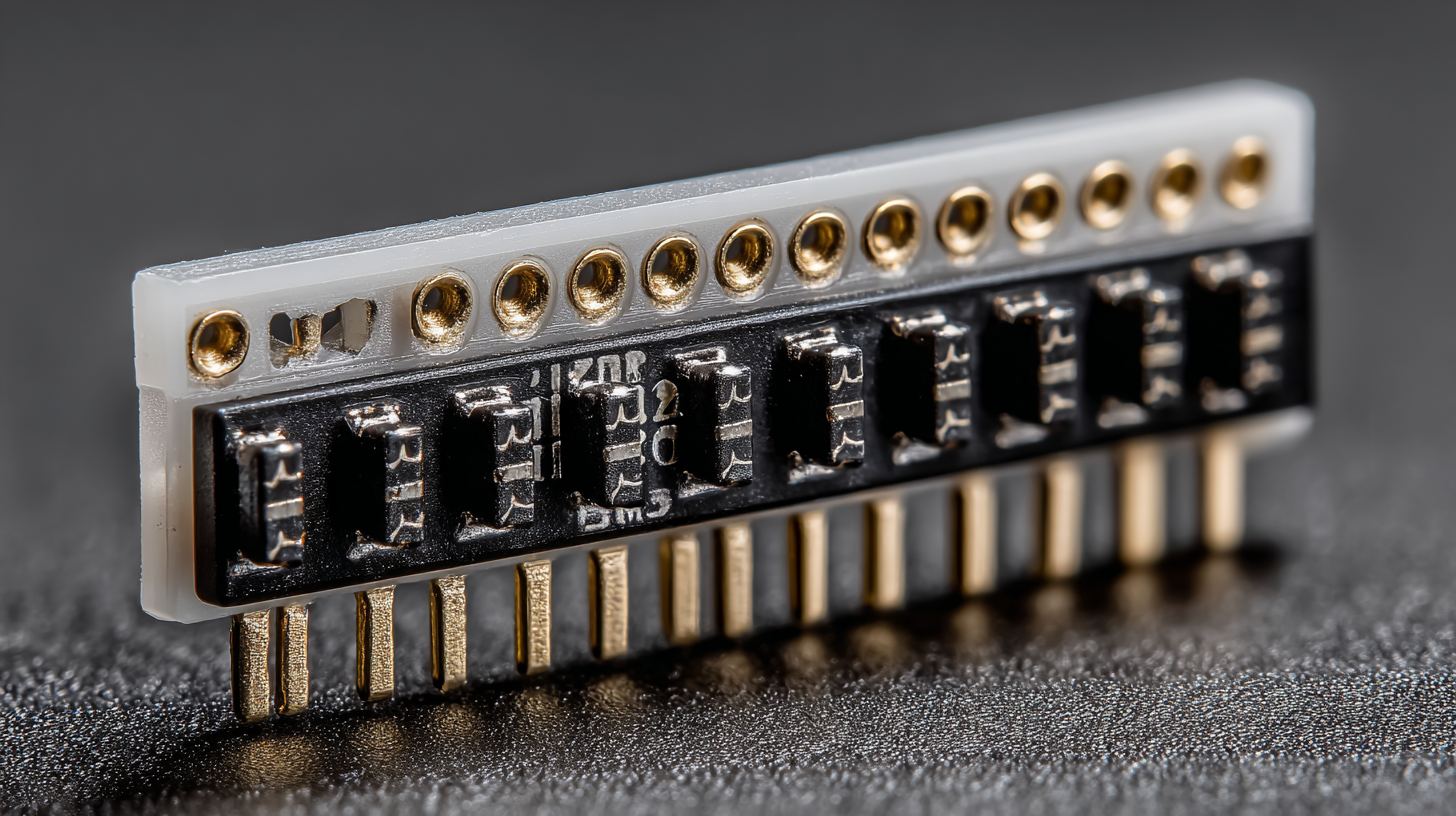

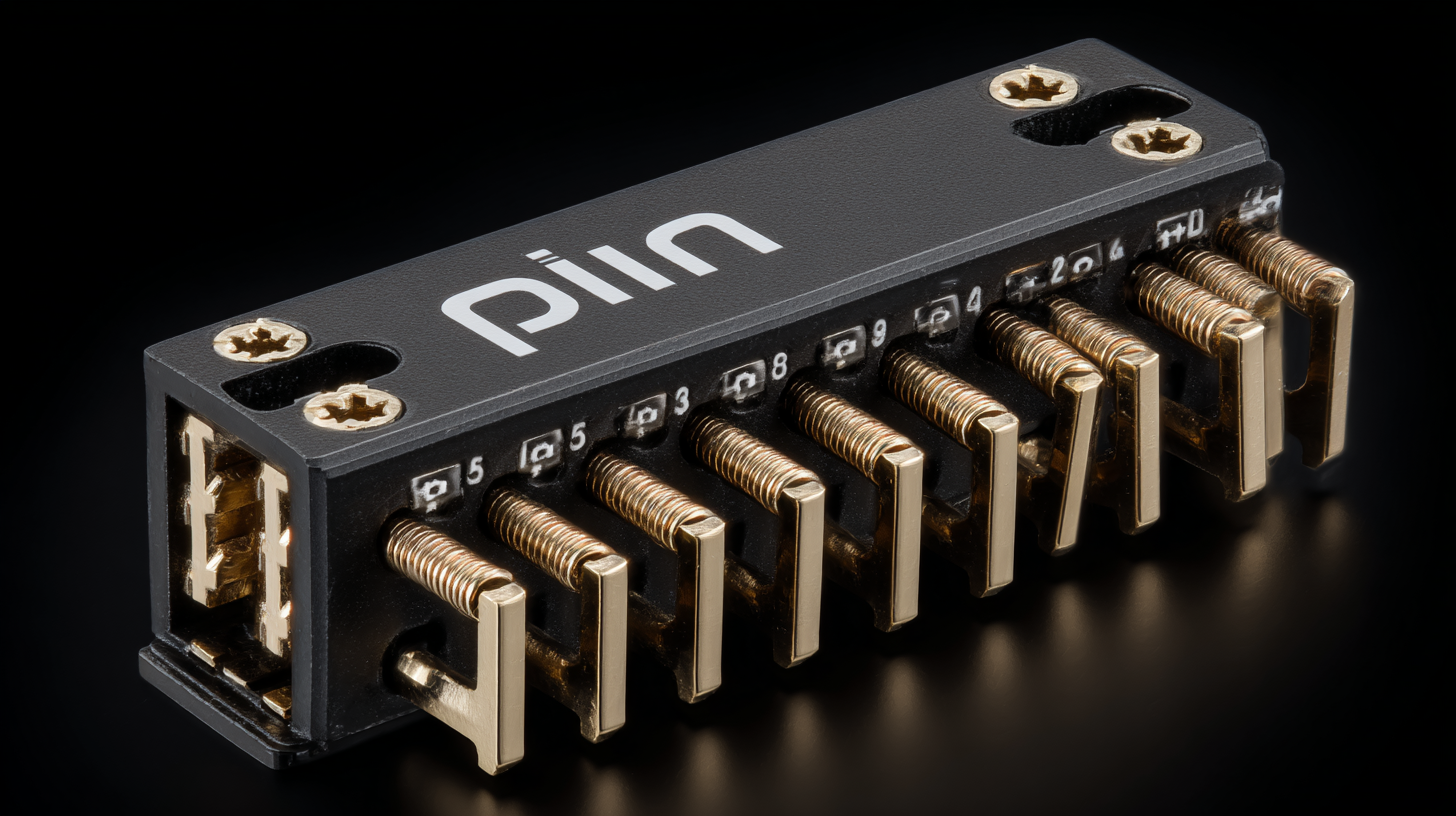

The top 10 pin header sockets revolutionizing connectivity are characterized by several key features that optimize functionality. Durability and high current ratings are paramount; for instance, sockets with gold-plated contacts can withstand multiple insertions while minimizing resistance and signal loss. A comprehensive report from MarketsandMarkets highlights that products with enhanced thermal management capabilities are gaining traction, as they prevent overheating and ensure consistent performance in high-load environments. Additionally, innovations in modular designs and customizable configurations are allowing engineers to tailor connections to specific application requirements, thus streamlining installation and maintenance processes. This combination of features not only enhances connectivity but also aligns with the industry’s shift towards more adaptable and efficient electronic systems.

As we look toward the future of connectivity, the pin header socket technology is poised to undergo significant advancements. According to a recent market report by Market Research Future, the global connector market is expected to reach $80 billion by 2025, driven by increasing demand for robust connectivity in consumer electronics, automotive, and industrial sectors. This growth highlights the essential role that pin header sockets play in enabling seamless communication between electronic components.

One of the emerging trends is the shift towards smaller, more efficient designs that cater to the miniaturization of electronic devices. The adoption of surface-mount technology (SMT) is on the rise, with an impressive increase of 30% year-over-year, indicating that manufacturers are prioritizing compact solutions without compromising performance. Additionally, innovations in materials, such as the use of high-temperature thermoplastics, are enhancing the durability and reliability of pin headers, making them more suitable for demanding applications.

Tips: When selecting pin header sockets, consider the specific requirements of your application, including the number of pins, pitch size, and current capacity. Always verify the compatibility with your existing components to ensure optimal performance. Moreover, stay updated on industry trends and new materials to make informed decisions that could enhance the longevity and efficiency of your designs.

In the context of global trade's evolution, the emergence of superior pin header sockets is poised to significantly enhance connectivity, thus boosting international trade prospects. As countries navigate the complexities of their economic relationships, such as the ongoing tensions between major powers, the demand for robust and efficient connectivity solutions becomes paramount. These innovative sockets not only promise improved data transfer and communication capabilities but also play a crucial role in supporting global supply chains that are often disrupted by geopolitical issues.

Additionally, as manufacturers around the world prioritize investments in digital infrastructure, the integration of advanced socket technology will provide a competitive edge in the global market. Countries, especially emerging economies like India, are increasingly focusing on enhancing their export capabilities through infrastructure improvements, which include modernizing connectivity solutions. The successful implementation of these technologies can act as a catalyst for economic growth, thereby fostering a more resilient and interconnected global trade environment.

| Rank | Socket Type | Pin Count | Material | Connection Speed (Gbps) | Projected Growth (%) | International Trade Impact |

|---|---|---|---|---|---|---|

| 1 | Standard Pin Header | 24 | Copper | 10 | 15% | High |

| 2 | High-Density Socket | 40 | Gold | 25 | 25% | Very High |

| 3 | Angled Pin Header | 16 | Nickel Plated | 5 | 10% | Moderate |

| 4 | Stackable Socket | 20 | Plastic | 2 | 20% | Low |

| 5 | Dual Row Socket | 32 | Tin Plated | 15 | 30% | High |