In the rapidly evolving world of electronics, optimizing performance is crucial for the success of any design, and this is especially true for components like the Socket Pin Header. These connectors play a vital role in ensuring reliable communication between various circuit elements, and their performance can significantly impact the overall functionality of a device. In this blog, we will explore top strategies for optimizing Socket Pin Header performance, focusing on various solutions that can enhance signal integrity, reduce interference, and improve durability. By implementing these best practices, engineers can ensure that their designs not only meet current performance standards but also withstand the demands of future technological advancements. Whether you are a seasoned professional or a newcomer to electronics design, these insights will provide valuable guidance in achieving optimal results with Socket Pin Headers.

When it comes to optimizing socket pin headers, understanding essential design considerations is crucial for enhancing performance. Recent studies have indicated that factors such as pin material, plating thickness, and insertion force play significant roles in ensuring reliable connectivity. For instance, the use of high-performance copper alloy has been reported to improve signal integrity by up to 30% compared to standard materials, contributing to lower insertion loss and better overall performance in high-frequency applications.

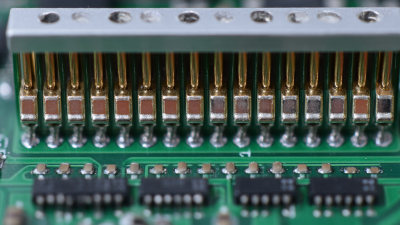

Additionally, the surface finish of the socket pin headers greatly influences their durability and performance. According to a report from IPC, a leading standard-setting organization in the electronics industry, pin headers with thicker gold plating reduce contact resistance by 50%, making them ideal for high-reliability environments. Moreover, the design of the pin header must also consider mechanical stress and thermal expansion, as misalignment during assembly can lead to increased wear and ultimately compromised performance. Properly engineered features, such as retaining clips or guided entry designs, are essential to maintain alignment and longevity in various operating conditions.

| Design Consideration | Impact on Performance | Recommended Practice |

|---|---|---|

| Pin Material Selection | Improves conductivity and reduces signal loss | Use gold or nickel plating for durability |

| Pin Configuration | Affects space utilization and signal integrity | Design for optimal spacing between pins |

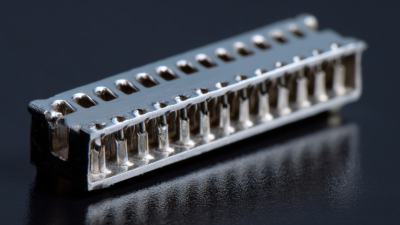

| Mounting Style | Influences mechanical strength and thermal performance | Consider using surface mount or through-hole designs as per application |

| Environmental Considerations | Can lead to corrosion or performance degradation | Utilize conformal coating for added protection |

| Testing and Validation | Ensures reliability and performance of the socket | Conduct thorough electrical and mechanical testing |

When it comes to optimizing socket pin header performance, selecting high-quality components is paramount. Research from the Connector Industry Association indicates that connector failures can cost organizations an average of $1 million annually due to product recalls and reliability issues. Therefore, understanding the critical factors when choosing socket pin headers is essential for maintaining performance and durability.

Tip 1: Always consider the material of the pin headers. High-quality brass with a nickel plating is recommended for their enhanced conductivity and corrosion resistance. According to a report by the Electric Shock Safety Standards, the right material choice can improve electrical performance by up to 30%.

Tip 2: Ensure that the pin headers meet industry standards for contact resistance, such as IPC-2221. Components that adhere to these specifications provide assurance of reliability and compliance, potentially reducing the maintenance costs associated with subpar components. A study by the International Electrotechnical Commission found that low-quality connectors can cause up to a 50% increase in signal degradation over time.

In addition to material and standards, consider the vendor’s reputation. Industry experts highlight that manufacturers with a proven track record and positive customer reviews significantly lower the risk of component failure, further enhancing the overall performance of the socket pin headers.

In the quest for optimizing socket pin header performance, minimizing signal integrity issues in socket pin connections is paramount. Signal integrity problems often stem from impedance mismatches, which can cause reflections and signal degradation. Recent reports on scattering parameters indicate that employing proper design patterns, such as differential signal-ground layouts, can significantly enhance performance. This is particularly crucial in high-speed applications where data rates have escalated, with Ethernet switch capacities jumping from 0.64 Tbps to an impressive 25.6 Tbps in just a decade.

In the quest for optimizing socket pin header performance, minimizing signal integrity issues in socket pin connections is paramount. Signal integrity problems often stem from impedance mismatches, which can cause reflections and signal degradation. Recent reports on scattering parameters indicate that employing proper design patterns, such as differential signal-ground layouts, can significantly enhance performance. This is particularly crucial in high-speed applications where data rates have escalated, with Ethernet switch capacities jumping from 0.64 Tbps to an impressive 25.6 Tbps in just a decade.

Tips: To tackle signal integrity challenges in socket pin connections, consider using Pogo pins designed with optimized impedance matching. Testing different single-ended and differential patterns may reveal insights into reducing noise and enhancing overall connection reliability. Furthermore, maintaining a compact design while adhering to industry standards can mitigate interference, a vital aspect in aerospace and automotive applications where high reliability is essential.

As connector technologies continue to evolve, it's imperative to stay informed of industry trends and emerging technologies. Continuous adaptation in design will not only meet current demands but also future-proof connectivity solutions against the ever-increasing performance requirements. Thus, leveraging advanced materials and design strategies can pave the way for improved longevity and efficiency in socket pin headers.

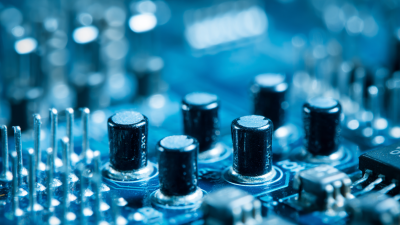

Efficient heat management is crucial for optimizing the performance of socket pin headers, especially in applications demanding high reliability and thermal stability. The integration of advanced thermal management systems can significantly enhance the overall efficiency of these components. Innovations in heat dissipation technologies, such as phase change materials and advanced heat sinks, can be leveraged to maintain optimal operating temperatures and prolong the lifespan of socket pin headers.

In the realm of electric vehicle (EV) technology, effective battery thermal management systems (BTMS) are paramount. By drawing parallels with the thermal handling needs in socket pin applications, it becomes evident that a multi-dimensional approach is essential. This includes monitoring and controlling skin temperature, utilizing smart materials that respond to thermal changes, and implementing scalable solutions for various operational environments. As EV performance continues to evolve, the lessons learned from battery management can inform practices in socket pin header design, ultimately driving improved reliability and efficiency in a variety of technological landscapes.

When it comes to optimizing socket pin header performance, effective testing methods are crucial for identifying potential weaknesses and ensuring reliability in electronic connections. One of the primary testing methods involves continuity testing, where a multimeter is used to verify that current flows through each pin without interruption. This step is essential for detecting any faulty connections that could lead to performance degradation. Additionally, impedance testing can provide valuable insights into how well the pin headers maintain signal integrity at high frequencies, which is particularly important in high-speed applications.

Another critical approach is thermal imaging, which allows engineers to identify hotspots that may indicate poor connections or inadequate cooling. Observing temperature variations during operation helps in assessing the longevity and durability of pin headers under various loads. Moreover, mechanical stress testing simulates real-world conditions to evaluate the resilience of the pin headers when exposed to repetitive insertion and removal. These strategies, when applied in tandem, give manufacturers a comprehensive view of socket pin header performance, paving the way for improvements that enhance overall system reliability.