In the rapidly evolving landscape of electronics design, the selection of components plays a crucial role in ensuring functionality and reliability. The 2mm Pin Header Socket has emerged as a vital connection solution in modern electronic assemblies, catering to a broad range of applications from consumer electronics to industrial automation. According to a recent industry report by MarketsandMarkets, the global market for electronic connectors, including pin header sockets, is projected to reach USD 73.1 billion by 2025, growing at a CAGR of 5.8%. This growth is driven by the increasing demand for miniaturization and enhanced connectivity in devices. As designers seek to optimize performance while minimizing space, understanding the key strategies for selecting the best 2mm Pin Header Socket becomes paramount. This blog will explore these strategies and highlight emerging trends that are shaping the electronics design industry in 2025 and beyond.

In the rapidly evolving landscape of electronics design, the selection of components plays a crucial role in ensuring functionality and reliability. The 2mm Pin Header Socket has emerged as a vital connection solution in modern electronic assemblies, catering to a broad range of applications from consumer electronics to industrial automation. According to a recent industry report by MarketsandMarkets, the global market for electronic connectors, including pin header sockets, is projected to reach USD 73.1 billion by 2025, growing at a CAGR of 5.8%. This growth is driven by the increasing demand for miniaturization and enhanced connectivity in devices. As designers seek to optimize performance while minimizing space, understanding the key strategies for selecting the best 2mm Pin Header Socket becomes paramount. This blog will explore these strategies and highlight emerging trends that are shaping the electronics design industry in 2025 and beyond.

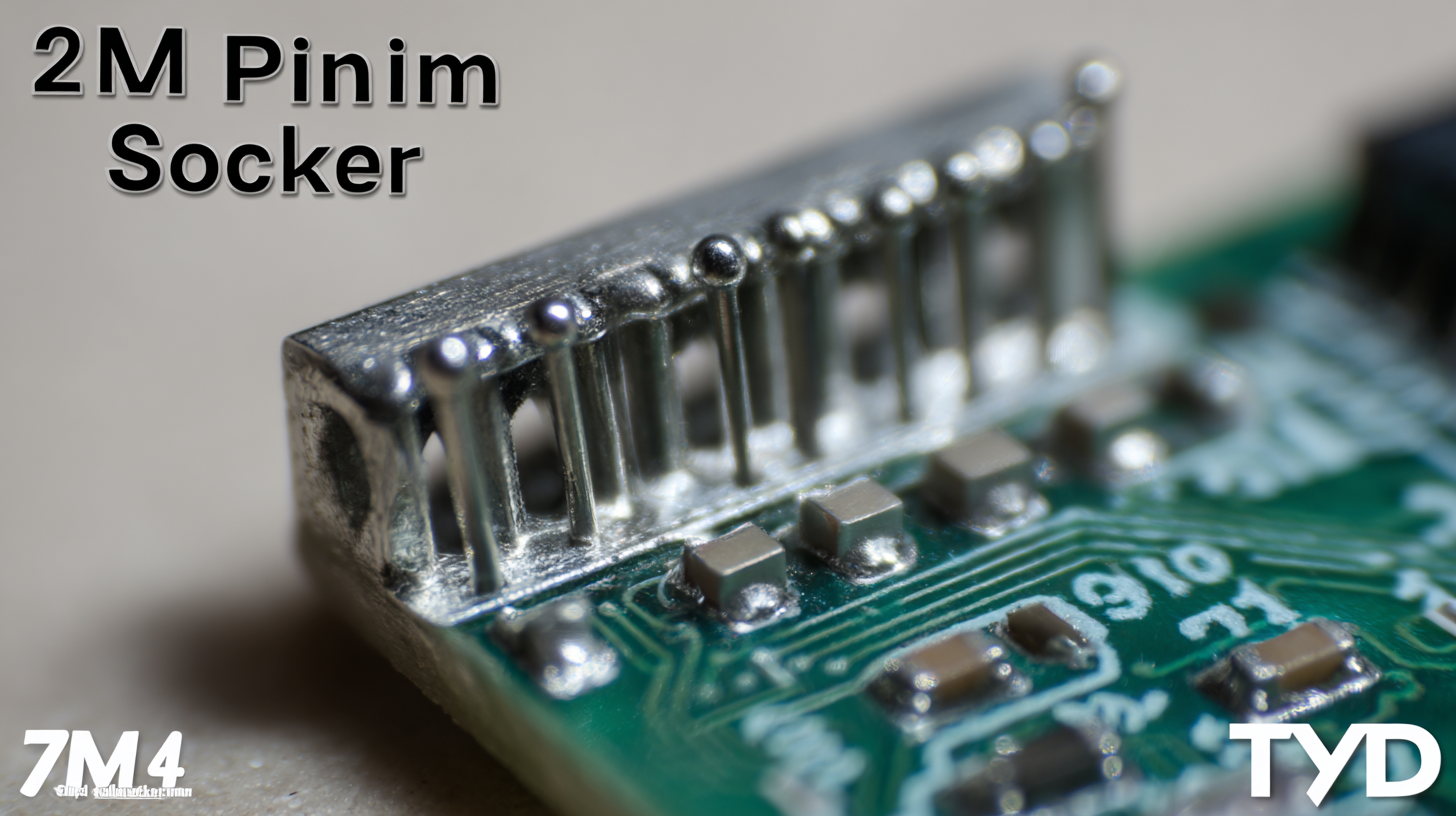

Understanding the importance of 2mm pin header sockets in electronics design is crucial for developing reliable and efficient devices. As the demand for compact and powerful electronics grows, the need for connectors that can facilitate seamless communication between various components becomes even more imperative. In particular, 2mm pin header sockets offer a perfect solution for applications requiring a high density of connections. Their compact size allows electronic designers to maximize board space while ensuring effective data transfer, especially in ever-evolving technologies such as IoT.

Recent advancements in connector technology, including the introduction of new micro connectors and enhanced design features, highlight the ongoing innovation aimed at improving performance and reliability in electronic design. As engineers increasingly integrate multiple sensors and devices using I2C ecosystems, the role of 2mm pin header sockets becomes even more critical. The right choice of sockets not only enhances the functionality of the device but also contributes significantly to the overall efficiency and longevity of the electronic systems.

| Parameter | Description | Importance |

|---|---|---|

| Pitch Size | The distance between the centers of adjacent pins. | Ensures proper spacing for compatibility with connectors. |

| Material | The material used for the socket, typically plastic and metal alloys. | Affects durability, conductivity, and temperature resistance. |

| Contact Resistance | The resistance between the contacting surfaces of the socket. | Critical for signal integrity and power efficiency. |

| Mounting Type | How the socket is attached to the PCB (through-hole or surface mount). | Impacts assembly process and overall design flexibility. |

| Current Rating | Maximum current the socket can safely carry. | Ensures reliable operation without overheating. |

| Operating Temperature | The temperature range in which the socket functions properly. | Vital for ensuring long-term use in varying environments. |

| Insulation Resistance | Resistance to electrical leakage between contacts. | Important for preventing short circuits and device failure. |

When selecting a 2mm pin header socket for your electronics design, understanding key specifications is crucial for ensuring compatibility and performance. First and foremost, consider the current rating and voltage requirements of your application. Choosing a socket that can handle the required current load while maintaining a safe voltage threshold is essential for preventing overheating and ensuring reliable connections. Additionally, the materials used in construction, such as the housing and contact plating, can significantly influence durability and conductivity.

Another critical specification to take into account is the pitch and alignment of the pins. A well-aligned socket is vital to ensuring seamless connectivity and reducing the risk of damage during mating. Factors like insertion force and retention also play a role; it's important to choose a socket that allows for easy insertion and removal while still holding the pins securely in place, preventing accidental disconnections.

Another critical specification to take into account is the pitch and alignment of the pins. A well-aligned socket is vital to ensuring seamless connectivity and reducing the risk of damage during mating. Factors like insertion force and retention also play a role; it's important to choose a socket that allows for easy insertion and removal while still holding the pins securely in place, preventing accidental disconnections.

As technology evolves, like the recent introduction of advanced single-board computers with enhanced features and connectivity options, the importance of high-quality components becomes even more pronounced. Ensuring that your pin header sockets meet these specifications will significantly contribute to the overall success of your electronic designs, particularly as you incorporate new technologies into your projects.

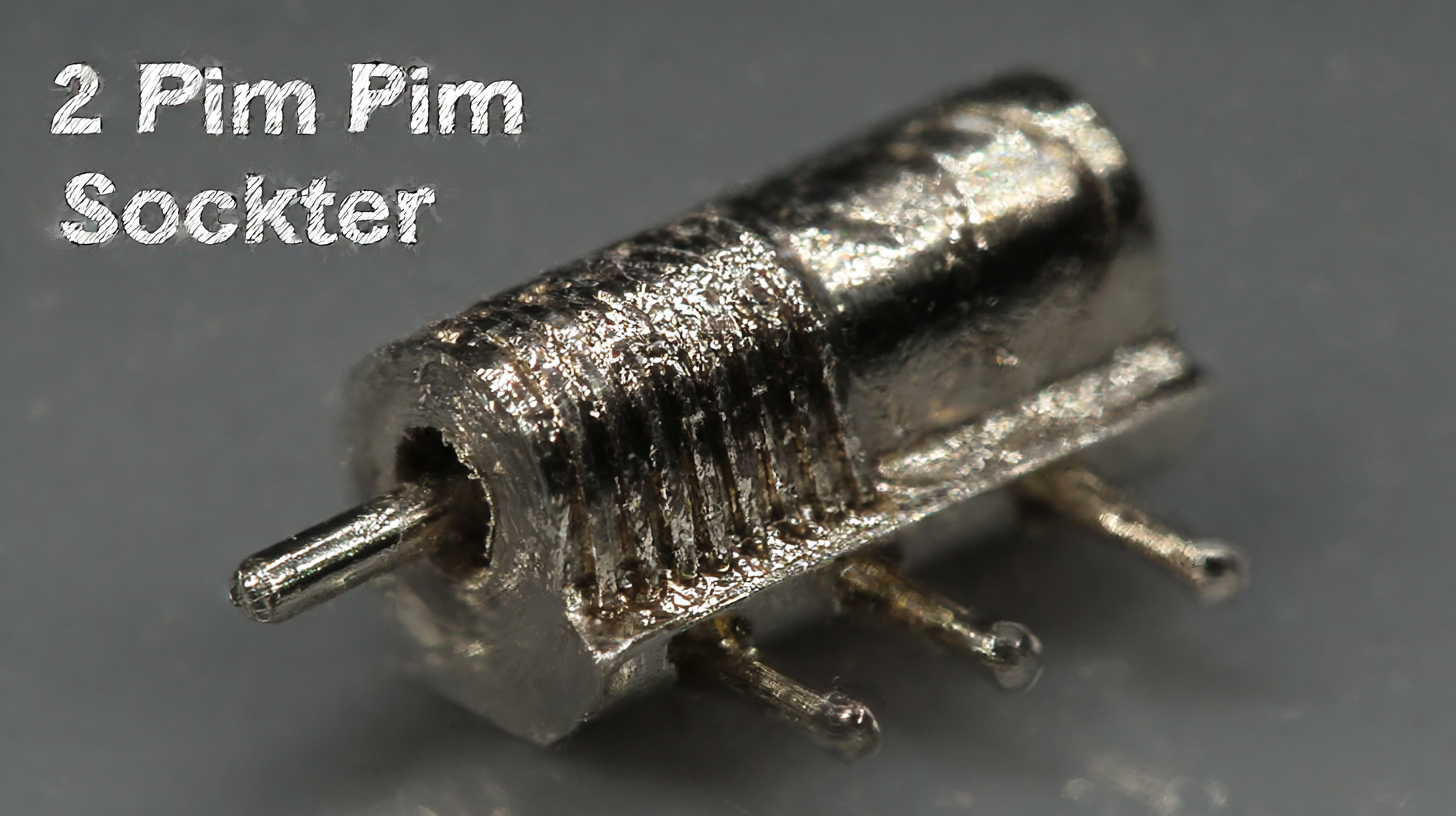

In the realm of electronics design, 2mm pin header sockets have become increasingly prevalent due to their compact size and versatility. Commonly utilized in applications such as compact consumer electronics, telecommunications, and industrial equipment, these sockets facilitate efficient connections in densely packed environments. According to a recent market analysis by Mordor Intelligence, the connector market is expected to grow at a CAGR of 5.2% from 2021 to 2026, driven largely by the rising demand for miniaturized electronic components.

One notable use case for 2mm pin header sockets is in the development of IoT devices. With the global IoT market projected to reach $1.6 trillion by 2025, designers are under pressure to create smaller, lighter devices without sacrificing performance. The reliability and ease of use offered by 2mm pin headers make them a preferred choice for engineers looking to optimize space while ensuring robust connectivity. Furthermore, these sockets are often found in prototyping and hobbyist projects, where their standardized dimensions allow for seamless integration with various circuit boards and modules, as highlighted by industry leader Digi-Key in their component selection guides.

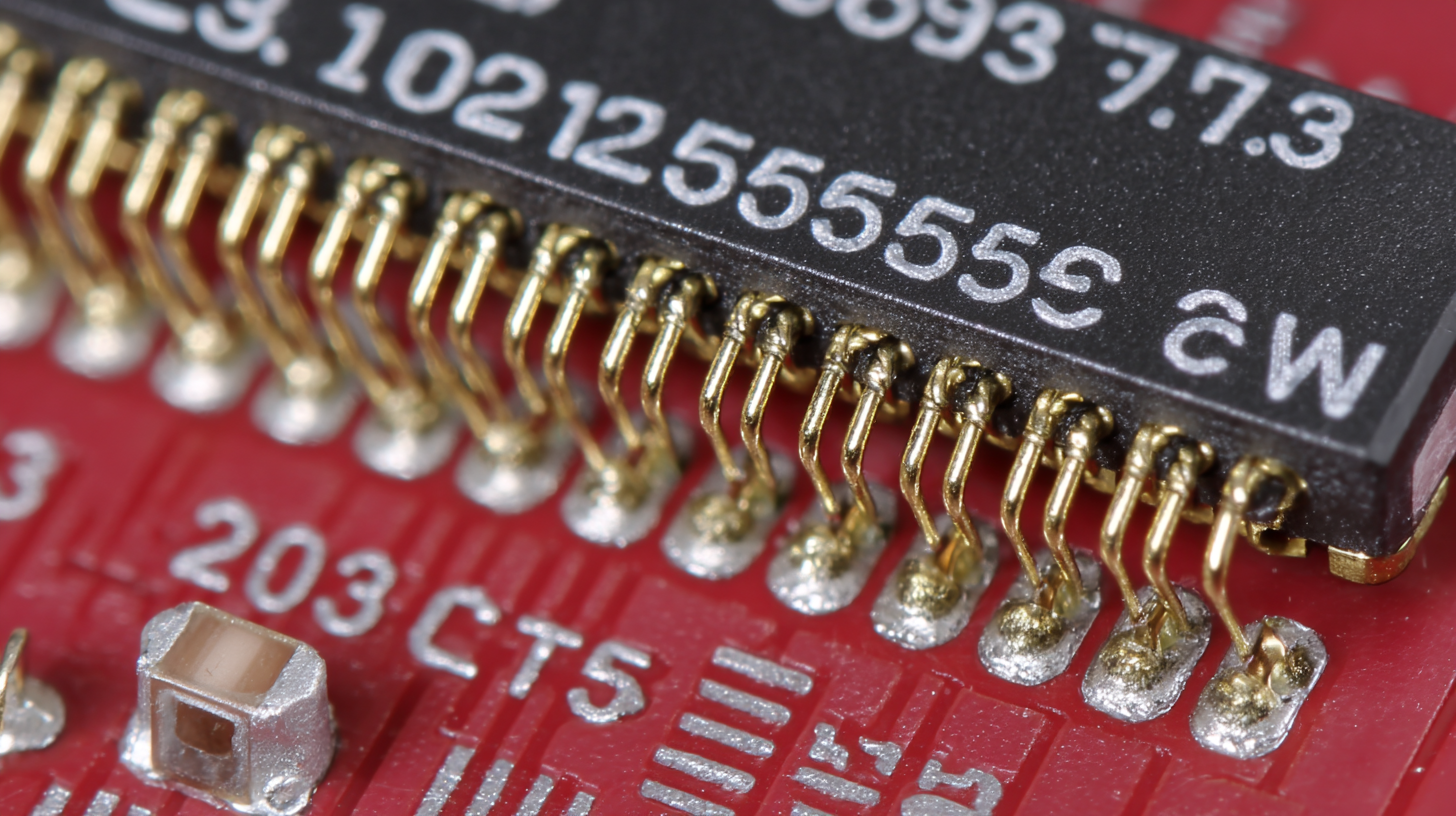

When selecting a 2mm pin header socket for your electronics design, it's crucial to analyze both the material composition and the durability features of the socket. The most common materials used in these sockets include thermoplastics and metal contacts.

Thermoplastics like nylon are favored for their excellent electrical insulation properties and resistance to heat, making them ideal for environments where thermal stability is essential. Additionally, metal contacts made from materials such as brass or phosphor bronze enhance conductivity and reduce the risk of oxidation, which can impair performance over time.

Thermoplastics like nylon are favored for their excellent electrical insulation properties and resistance to heat, making them ideal for environments where thermal stability is essential. Additionally, metal contacts made from materials such as brass or phosphor bronze enhance conductivity and reduce the risk of oxidation, which can impair performance over time.

Durability factors also play a significant role in the effectiveness of 2mm pin header sockets. Look for sockets that offer high cycle life ratings to ensure reliable connections through many insertions and removals. Mechanical strength, resistance to temperature fluctuations, and the socket's ability to withstand environmental stresses such as moisture and dust are vital considerations. Conducting tests for these durability aspects will provide insight into how the socket will perform in real-world applications, thus ensuring the longevity and reliability of your electronics design.

When it comes to electronics design, selecting the right 2mm pin header socket can significantly impact both performance and cost. A cost-benefit analysis reveals that investing in high-quality sockets might involve a higher initial expense but offers long-term savings through enhanced reliability and durability. For instance, high-quality sockets can withstand more insertion cycles, minimizing the risk of failure during critical operations.

Tip: Always evaluate the specific requirements of your project. If you're working on a prototype or a short-term application, standard sockets may suffice. However, for long-term projects where reliability is paramount, opting for high-quality options is advisable.

Another factor to consider is the application environment. High-quality 2mm pin header sockets are often more resistant to environmental conditions such as temperature fluctuations and moisture. This resilience can prevent issues that might arise from using standard sockets that are not designed for harsh conditions.

Tip: Conduct thorough research on the materials and specifications of the sockets. Choosing connectors made from materials like gold-plated contacts can enhance conductivity and reduce oxidation, leading to better performance over time.