In the realm of electronic components, the Socket Pin Header stands out as a critical interface that connects various circuit elements, ensuring seamless communication and functionality. According to recent industry reports, the global demand for connector components, including Socket Pin Headers, is projected to reach USD 78.9 billion by 2025, driven primarily by advancements in automation and the rising prevalence of consumer electronics. This significant growth reflects not only the essential role that these headers play in device assembly but also highlights the importance of understanding their technical specifications and industry standards. As manufacturers strive to enhance the reliability and efficiency of their products, a comprehensive examination of the key parameters governing Socket Pin Headers becomes imperative, particularly when considering the advantages of after-sales service and maintenance costs associated with their usage.

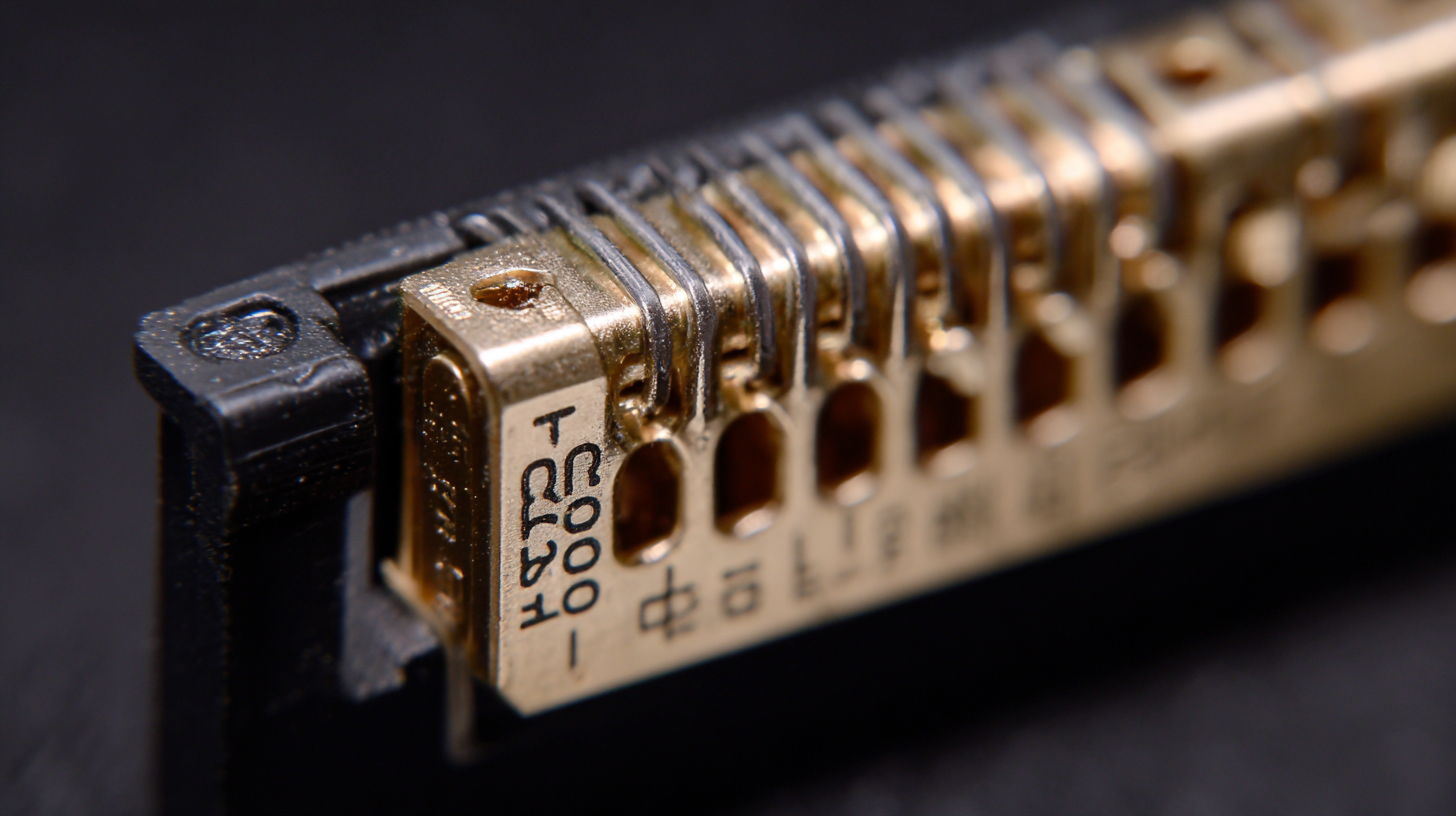

Socket pin headers are a vital component in electronic circuitry, providing a reliable means of connection between various components. These headers consist of a series of metallic pins arranged in a row and designed to receive connecting devices such as plugs. Understanding the specifications of socket pin headers is essential for engineers and designers alike, as these parameters determine performance, compatibility, and durability in electronic applications. For instance, typical dimensions for socket pin headers include a pitch of 2.54 mm, which ensures compatibility with standard connectors, alongside a robust construction material that ensures longevity against heat and wear.

When selecting a socket pin header, consider these tips for optimal performance: First, ensure that the operating temperature range suits your application; many headers function effectively between -40°C to +125°C. Secondly, reviewing the current rating of the header—often between 3A to 5A—can prevent potential failures in high-load scenarios. Lastly, always check for compliance with industry standards such as IPC-A-610 for quality criteria, which ensures that the components meet stringent reliability expectations.

Recent industry collaborations show how integral such specifications are for advancement in technology ecosystems. Innovative partnerships are leading to accelerated growth, similar to the recent developments in the digital advertising sector. As businesses and tech sectors continue to evolve, the importance of high-performing components like socket pin headers will grow, reinforcing their role in driving technological innovation.

This chart illustrates the key technical parameters of socket pin headers, including pin count, pitch size, material quality, voltage rating, and current rating. These specifications are critical for understanding the performance and application of socket pin headers in various electronic devices.

In the realm of socket pin headers, understanding key technical specifications such as voltage, current, and pin count is essential for selecting the right components for your projects. Voltage ratings dictate how much electrical energy a header can handle, while current ratings determine the maximum current flow without risking component failure. Pin count is vital as it relates to the number of electrical connections available, affecting how many devices or circuits can be interfaced concurrently.

When designing with socket pin headers, it’s crucial to consider electrical safety. Utilizing materials that either conduct electricity efficiently or insulate effectively can prevent hazardous situations. Always ensure that the specifications of your chosen headers meet industry standards for safety and reliability, especially when dealing with high-voltage applications or sensitive electronic devices.

**Tips:** When selecting socket pin headers, match the voltage and current ratings to the components in your circuit to ensure optimal performance. Additionally, always refer to the latest industry standards, such as those developed by relevant organizations for electrostatic discharge testing, to ensure compliance and safety in your designs.

| Parameter | Value | Unit |

|---|---|---|

| Nominal Voltage | 5 | V |

| Maximum Current | 3 | A |

| Pin Count | 16 | pins |

| Operating Temperature Range | -40 to +85 | °C |

| Insulation Resistance | 1000 | MΩ |

| Contact Resistance | 20 | mΩ |

| Material | Phosphor Bronze | - |

| Plating Thickness | 0.2 | µm |

When it comes to selecting the best socket pin headers, understanding industry standards is crucial. Compliance and certification ensure that these components meet the rigorous demands of various applications, from consumer electronics to aerospace. Socket pin headers must adhere to standards set by organizations like IPC and UL, which define the quality and performance expectations. Being familiar with these certifications not only helps in selecting reliable products but also positions your project for success in its respective market.

Tips for ensuring compliance include verifying that the socket pin headers are tested for temperature tolerance, solderability, and mechanical stress. Always check for certification marks on the packaging or product documentation, as this can help guarantee that the component has undergone thorough testing. It's also beneficial to collaborate with suppliers who prioritize industry standards, as they can provide insights on the best practices and emerging regulations within the field.

Moreover, keep an eye on evolving standards, as technology and consumer expectations change rapidly. Regularly updating your knowledge about the latest industry specifications will help you stay ahead and make informed choices when sourcing socket pin headers. Leveraging these tips will enable you to select high-quality components that not only meet current requirements but are also future-proofed for potential innovations.

When selecting the right socket pin header for your project, several key factors warrant careful consideration. Firstly, the configuration of the pin header is paramount. It’s crucial to match the pin count and spacing to your specific application requirements. Standard pin headers may come in various row and column arrangements, so identifying the layout that fits your printed circuit board (PCB) design will streamline the assembly process and ensure proper connectivity.

Another critical factor is the material and durability of the socket pin header. High-quality materials such as brass or gold-plated contacts can enhance conductivity and resistance to corrosion, significantly extending the lifespan of the connection. Thermal and electrical ratings should also be evaluated; headers must be able to withstand the environmental conditions and operational demands of their applications. Finally, compliance with industry standards—such as RoHS and IPC specifications—ensures that the components are reliable and safe for long-term use. Thus, taking the time to assess these factors can lead to a more efficient and effective connection in your electronic designs.

Socket pin headers play a crucial role in various electronic devices and systems. From consumer electronics to industrial machinery, these connectors are essential for facilitating communication between different components. In robotics, for example, socket pin headers are used to connect sensors, motors, and controllers, ensuring seamless functionality in real-time applications. Their reliability and ease of soldering make them a favored choice among designers and engineers for prototyping and production.

Tip: When selecting socket pin headers for your projects, pay close attention to their pitch size and row configuration to ensure compatibility with other components. Additionally, consider the material used for the contacts; gold-plated contacts, for example, offer improved conductivity and corrosion resistance.

In automotive applications, socket pin headers are integral to various systems, such as engine control units and infotainment systems. They allow for robust electrical connections while enabling easy maintenance and upgrades. Customization options, such as color-coded pins, can also aid in organizing wiring schematics for complex systems.

Tip: It's beneficial to have a variety of socket pin headers on hand, as different projects may require different sizes and configurations. This way, you can quickly adapt to changing design specifications without delays.