In the rapidly evolving electronics industry, the choice of components plays a crucial role in the success of any project, and among these components, the Pin Header Socket stands out for its versatility and reliability. According to a recent industry report by ResearchAndMarkets, the global connector market, which includes pin header sockets, is expected to reach USD 70 billion by 2025, driven by the increasing demand for consumer electronics and IoT devices. With a plethora of options available, selecting the best Pin Header Socket tailored to your specific project needs can be daunting. This blog aims to provide insights into key factors to consider when making this selection, ensuring that you can navigate the complexities of this essential electronic component effectively and efficiently.

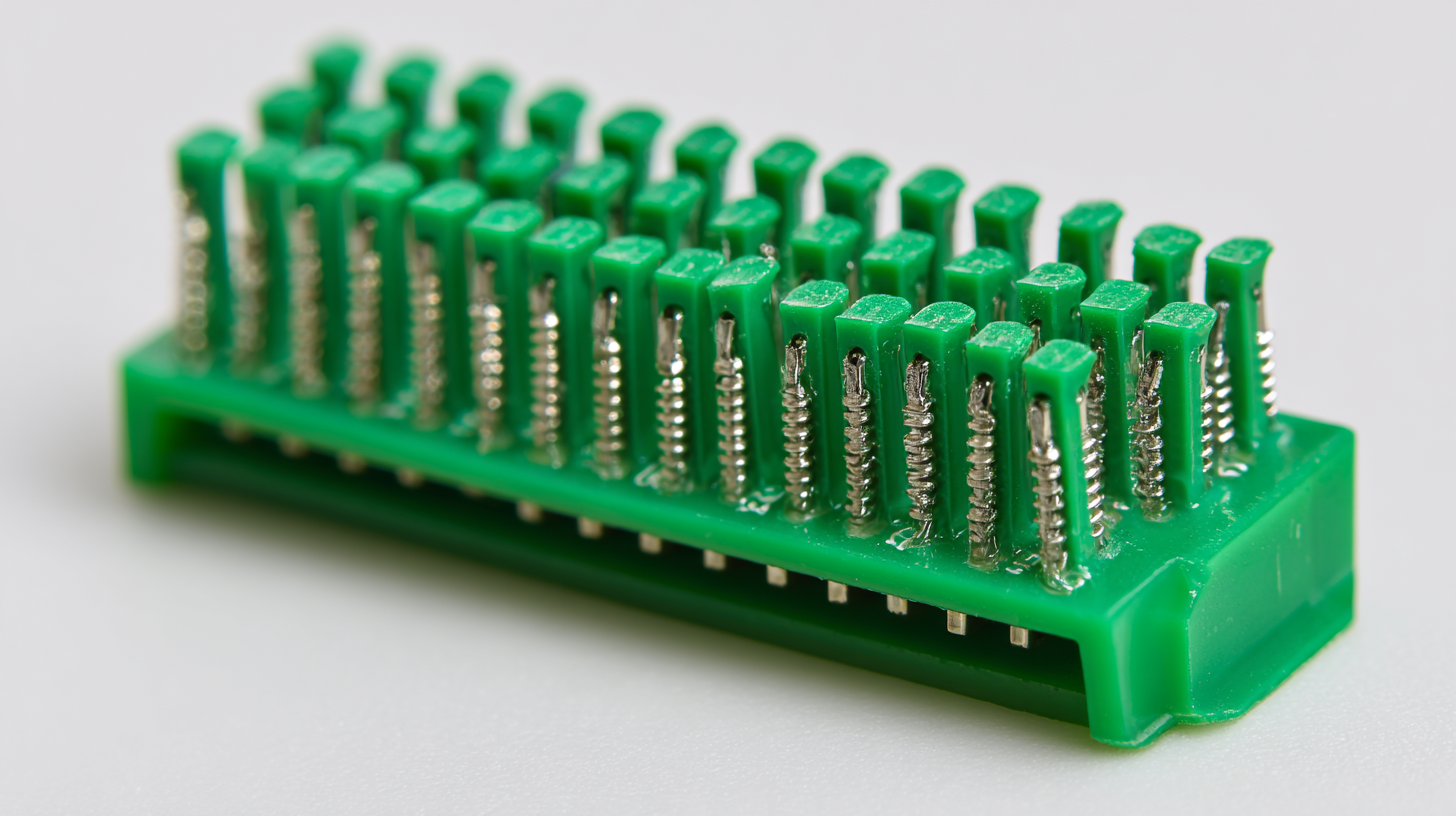

When selecting the best pin header socket for your project needs, it's essential to understand the various types available and their specific applications. Pin header sockets come in different configurations, including single-row and double-row designs, and can vary in pin count and spacing. For instance, a typical 2.54mm pitch socket is widely used for various electronic connections, making it suitable for prototyping boards and modular designs. According to industry reports, the demand for these sockets has surged by approximately 7% annually, driven by their integration in both consumer electronics and industrial applications.

One exemplary type is the M8 3 pin male circular aviation connector, renowned for its durability and reliability in harsh environments. Such connectors are often employed in applications requiring robust connections, such as automotive and manufacturing sectors. With their compact design, M8 connectors not only save space but also offer effective resistance against dust and moisture, aligning with the growing trend towards miniaturization in electronics.

Moreover, the advent of USB Type-C technology signifies a pivotal shift in connectivity standards. This connector, resembling the size of an old USB micro-B port but offering enhanced versatility, has become increasingly prevalent in smartphones and other portable devices. Reports illustrate that by 2023, over 60% of mobile devices will incorporate USB Type-C due to its faster data transfer rates and the convenience of reversible plug design, further emphasizing the importance of selecting appropriate connectors like pin header sockets in modern electronic projects.

When selecting pin header sockets for electronic projects, it's essential to navigate common challenges that can arise during the decision-making process. One prevalent issue is compatibility; as the variety of connectors expands, ensuring that the selected socket matches the specifications of the board is critical. According to industry reports, approximately 30% of connection failures are attributed to mismatched pin configurations, highlighting the importance of verifying the technical requirements of both the socket and the PCB.

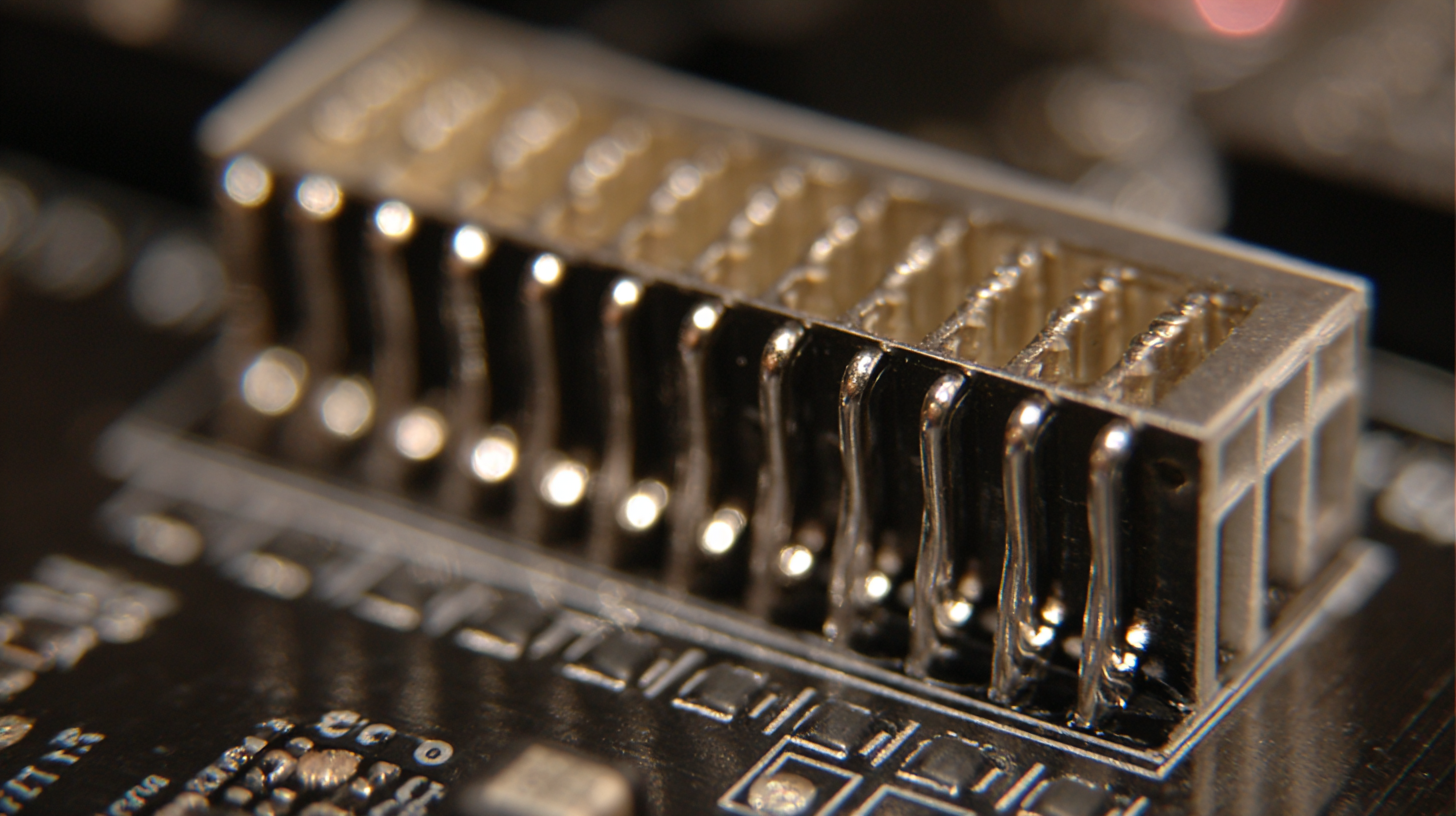

Another challenge relates to the power handling capabilities of pin headers. In recent discussions surrounding melting connectors, particularly in high-performance graphics cards, it has become clear that some designs may not adequately account for the thermal and electrical stresses during operations. Industry standards suggest that connectors must be able to handle at least 20-30% more current than the expected load to account for unexpected surges. Engaging with manufacturer data and adhering to recommended ratings can help mitigate risks associated with overheating and connector failure, ensuring reliability in demanding applications.

When selecting the best pin header socket for your project, it is crucial to consider several key factors that will impact both functionality and reliability. Firstly, the pitch, or spacing between pins, plays a significant role in compatibility with various components. Common pitches include 2.54mm (0.1 inches) and 1.27mm (0.05 inches). Choosing the right pitch will ensure a proper fit and efficient performance within your circuit design.

Another important factor to consider is the material and plating of the pins. For high-frequency applications, look for sockets with gold or tin plating, as these materials provide better conductivity and reduce the risk of corrosion over time. Additionally, the current rating and temperature range should be evaluated to ensure that the socket can handle the electrical demands of your project. Lastly, consider the mounting style—whether through-hole or surface mount—as this will influence your overall design layout and assembly process. By carefully evaluating these factors, you can select a pin header socket that meets your project needs effectively.

When working with pin header sockets, troubleshooting can often be a challenge, particularly when projects do not behave as expected. The first step in addressing issues is to systematically verify all connections. Ensure that each pin is securely seated in its corresponding socket, as a loose connection can lead to intermittent failures. Additionally, using a multimeter to check for continuity can help identify any pins that may not be making proper contact.

Another common problem arises from incorrect alignment during assembly. Misaligned pins can cause short circuits or failure to recognize devices. Be sure to examine the orientation of both the pins and the socket, as even a slight misalignment can affect functionality. If you experience erratic behavior or failure during testing, re-evaluating the connections and alignment can often yield a quick resolution. Remember to keep your workspace free from static electricity, as this can also cause damage to sensitive electronic components. By following these troubleshooting steps, you can effectively diagnose and fix issues with pin header sockets, ensuring a smoother project workflow.

The chart above represents the importance ratings of various factors when selecting a pin header socket for a project. Factors such as compatibility and contact resistance are critical, while availability is slightly less prioritized.

When integrating pin header sockets into your project, it’s crucial to consider the specific requirements of your application. First, ensure that the pin pitch matches your circuit board design to facilitate proper connections. A common pin pitch is 2.54mm, but it is essential to double-check the specifications of both the socket and the header pins to avoid compatibility issues.

Tip: Utilize a multimeter to test the continuity and connectivity of the pin header sockets during your prototyping phase. This step can help you identify any potential issues before finalizing your design, ensuring reliability in your connections.

Another best practice is to choose pin header sockets that offer greater durability, especially if your project will undergo frequent assembly and disassembly. Look for sockets that have gold or tin plating, as this can enhance the lifespan of your connections and reduce the risk of corrosion over time.

Tip: Document the pin configuration and layout of your project. This will assist not only in streamlining the assembly process but will also be invaluable for troubleshooting potential connection problems in the future.