In the world of electronics, reliable connections are paramount for optimal device performance, and male header pins play a crucial role in ensuring these connections are robust and secure. According to a report by MarketsandMarkets, the global connector market, which includes male header pins, is expected to reach $79.22 billion by 2026, growing at a CAGR of 5.9% from 2021. These components are not only integral to PCB designs but are also essential for facilitating seamless communication between various electronic devices. The versatility of male header pins allows them to cater to diverse applications, from consumer electronics to industrial machinery. Furthermore, a study by ResearchAndMarkets highlights that the increasing demand for compact and lightweight electronic devices necessitates reliable connection solutions like male header pins. As technology continues to evolve, understanding the significance of these components becomes essential for engineers and manufacturers striving for quality and reliability in their products.

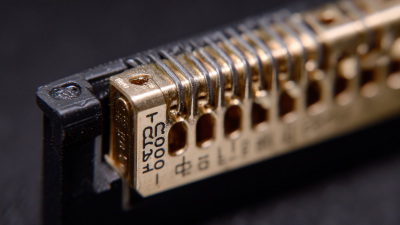

Male header pins are integral components in the realm of reliable electronics connections. These pins, typically made from high-conductivity materials like gold or tin-plated brass, are designed to establish secure electrical connections between circuit boards and other electronic components. According to industry reports, approximately 80% of electronics fail due to poor connections, emphasizing the crucial role male header pins play in enhancing device reliability. They allow for easy assembly and disassembly while ensuring consistent performance over time, which is vital for both prototyping and mass production.

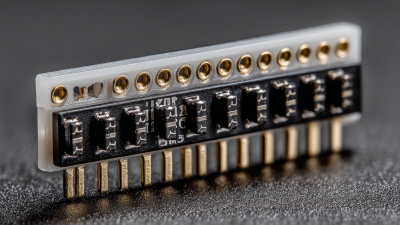

When using male header pins, it's essential to consider the pin pitch and header style to ensure compatibility with your project. For instance, a standard 2.54mm pitch is widely used in many applications. It’s advisable to use quality pins that can handle the required current specifications; typically, a single pin can manage currents up to 3A at 30V.

Tips: Always ensure that the pins are properly soldered; weak solder joints can lead to intermittent failures. Additionally, consider using locking headers for applications that demand higher vibration resistance, which will enhance the durability of your electronic connections. Remember, investing in quality male header pins can significantly reduce maintenance costs in the long run.

When selecting the right male header pins for your electronics project, it's crucial to consider both functionality and compatibility. Male header pins come in various formats, including pin counts, sizes, and materials. According to a recent industry report by Electronics Weekly, over 70% of PCB designers listed compatibility as a key factor in choosing header pins for their projects. This highlights the importance of ensuring that the header pin's dimensions and layout match your circuit board's design for a reliable connection.

Furthermore, the quality of materials used in male header pins can significantly impact their performance. A study published by the International Journal of Electronics Engineering noted that using high-grade copper with appropriate plating can minimize contact resistance, which is vital for maintaining signal integrity. It was found that low-quality header pins could lead to a 15% increase in signal degradation, jeopardizing the overall efficiency of electronic systems. Therefore, investing time in selecting the right male header pins is essential for both functionality and reliability in your electronic projects.

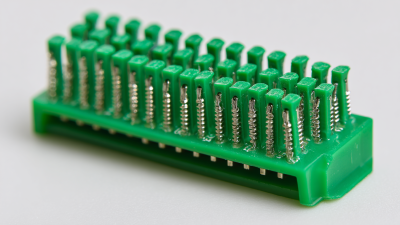

When it comes to installing male header pins, precision and technique are crucial for ensuring reliable electronics connections. The first step involves selecting the right type of male header pins that fit your circuit board's specifications. Depending on the application, you might choose between straight or angled pins. Ensure you have a quality soldering iron and solder that are appropriate for the pin size; this will determine the longevity and strength of the connections.

Next, prepare the circuit board by cleaning the area where the pins will be installed. Insert the male header pins into the designated holes, ensuring they are flush with the surface. For a strong connection, apply an appropriate amount of heat from the soldering iron to each pin and feed solder into the joint. Be mindful of overheating, as this can damage both the pins and the printed circuit board. After soldering, inspect each connection for quality to guarantee that your electronic device will function properly without interruption.

When working with male header pins in electronic projects, avoiding common mistakes can ensure reliable connections. One frequent error is improper alignment during insertion. It's crucial to ensure that the pins are straight and aligned with the corresponding headers before applying force. Misalignment can lead to bent pins or poor connections, which ultimately compromise the functionality of the device.

Another common mistake is using excessive force when connecting the pins. This can damage both the pins and the header socket. Instead, gently apply pressure and ensure that the pins slide into place smoothly. Finally, neglecting to check pin orientation can lead to incorrect wiring configurations, which can be costly and time-consuming to troubleshoot. Taking the time to verify the orientation before making connections can save you from significant headaches down the line.

Male header pins are pivotal in enhancing the stability of electronic connections. One of their primary benefits is the secure and reliable interface they provide. The design of male header pins allows for a firm connection with female sockets, minimizing the risk of disconnection or electrical failure. This strong mechanical coupling is particularly advantageous in environments subjected to vibration or movement, making male header pins ideal for automotive and industrial applications.

Another significant advantage is their versatility across various electronic components. Male header pins can accommodate multiple configurations, allowing engineers to tailor connections to specific circuit designs and requirements. This adaptability not only streamlines the assembly process but also contributes to more effective space utilization on circuit boards. By incorporating male header pins, designers can enhance the overall reliability of their electronic systems, leading to improved performance and longevity.