In the fast-evolving landscape of electronics manufacturing, the importance of efficiency cannot be overstated. The introduction of innovative components has played a crucial role in propelling industry advancements, with the "Pin Header Socket" emerging as a key player in manufacturing trends for 2023. According to a recent report by Research and Markets, the global market for connector components is expected to reach $85 billion by the end of this year, with pin header sockets significantly contributing to this growth due to their versatility and reliability in circuit board connections.

Industry expert Dr. John Stevens, a leading authority on electronic connectors, highlights the pivotal role of pin header sockets in enhancing operational efficiency. He states, "Incorporating high-quality pin header sockets not only improves assembly speed but also reduces the risk of connection failures, which is essential for meeting the increasing demands of today’s electronics." As manufacturers strive to integrate more compact and efficient solutions, the pin header socket's adaptability ensures that systems remain robust, flexible, and aligned with emerging technological trends.

Overall, the advancements in pin header socket technology are a testament to the industry's commitment to innovation. As we delve further into 2023, it is evident that these components will continue to shape manufacturing processes, leading to enhanced productivity and lower operational costs. Exploring the dynamic role of pin header sockets will shed light on their significant impact on electronics manufacturing, ultimately driving the sector toward a more efficient future.

Pin header sockets are increasingly recognized for their crucial role in streamlining production processes within the electronics manufacturing industry in 2023. As manufacturers seek ways to enhance efficiency, the integration of pin header sockets provides a reliable connection solution that significantly reduces assembly time and minimizes errors. Recent industry reports indicate that the global demand for connectors is expected to grow by over 5% annually, highlighting the importance of innovative assembly techniques that pin header sockets facilitate.

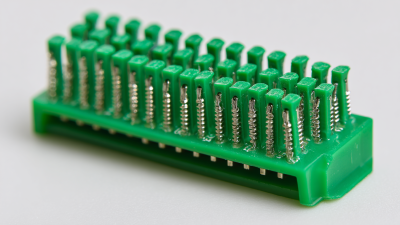

One noteworthy trend is the advancement in automated assembly lines, which incorporate precision engineering techniques to optimize the connector assembly process. For instance, recent developments have introduced multi-station lines that automate the intricate assembly of connectors, improving accuracy and speed while reducing labor costs. This shift not only elevates production efficiency but also ensures higher quality and consistency in electronic components.

Tips for Implementing Pin Header Sockets:

In 2023, the electronics manufacturing landscape is witnessing transformative shifts driven by innovative design trends in pin header sockets. These crucial components facilitate seamless connections between various electronic devices, and their evolution is central to enhancing efficiency in manufacturing processes. According to a recent industry report by MarketsandMarkets, the global demand for pin header sockets is projected to grow by over 5% annually, reflecting their vital role in the burgeoning Internet of Things (IoT) sector which is expected to reach a market value of $1.1 trillion by 2026.

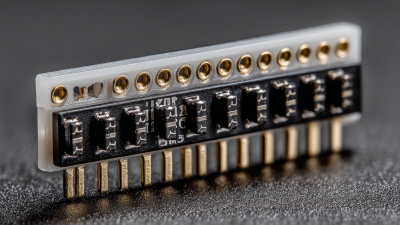

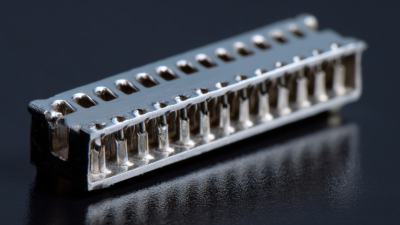

One of the most significant trends this year is the integration of advanced materials and miniaturized designs that improve reliability and performance. Manufacturers are increasingly adopting high-density configurations that allow for more connections in limited spaces, promoting compact designs in devices. A report from ResearchAndMarkets highlights that high-density interconnect (HDI) technology is anticipated to boost the efficiency of assembly lines by reducing component placement time by as much as 30%. Furthermore, the shift towards eco-friendly materials is gaining momentum, aligning with global sustainability goals and consumer preferences, which underscores the need for manufacturers to innovate continuously in design and functionality.

As manufacturers strive for greater cost efficiency in 2023, pin header sockets are emerging as a key component in reducing production expenses. A report from the Electronics Industry Association indicates that the integration of modular components like pin header sockets can lower assembly costs by up to 20%. These sockets not only simplify the assembly process but also enhance reliability, which decreases the frequency of repairs and replacements. This reduction in operational costs makes pin header sockets an attractive choice for companies looking to optimize their manufacturing budgets.

**Tip:** When selecting pin header sockets, consider the impact of material choices on overall costs. Using high-quality materials may increase initial investment but can lead to long-term savings through reduced maintenance and increased lifespan.

Moreover, the standardization of pin header sockets allows for more streamlined manufacturing processes. According to a recent study by TechNavio, manufacturers that leverage standardized components can see a decrease in production time by approximately 15%. This increase in efficiency directly correlates to savings, as less labor is required for assembly, allowing companies to allocate resources to other vital areas of production.

**Tip:** Always evaluate the potential for scalability when integrating pin header sockets into your designs. The long-term benefits of using these efficient components can significantly enhance both production speed and cost savings.

The evolution of pin header socket technology has played a pivotal role in shaping modern electronics manufacturing. As devices become increasingly compact and complex, the demand for reliable and versatile connection solutions has surged. Manufacturers are now leveraging advanced materials and precision engineering to enhance the performance of pin header sockets, ensuring that they can withstand the challenges of high-speed data transmission and increased thermal loads. This evolution is not only influencing the design of new electronic components but also allowing for greater flexibility in the assembly process.

Moreover, the shift towards automation in manufacturing processes has led to the development of specialized pin header sockets designed for robotic assembly. These components are engineered for easier handling and alignment, which streamlines production and reduces the likelihood of errors. As industries adopt smart manufacturing techniques, the integration of these innovative sockets is expected to drive greater efficiency and lower production costs, making them a linchpin in the future of electronics manufacturing.

This trend highlights how evolving technologies can significantly impact design and production strategies, ultimately leading to more innovative and reliable electronic products.

In 2023, the electronics manufacturing sector is witnessing a significant shift driven by the rising demand for pin header sockets. These components have become essential due to their versatility in connecting various electronic devices, making them a staple in industries ranging from telecommunications to consumer electronics. As the global connector market is projected to reach USD 109.2 billion by 2035, with a steady CAGR of 3.9%, the influence of pin header sockets in this growth trajectory cannot be understated.

Regions such as Asia Pacific are at the forefront of this trend, with the connector market in this area expected to surge from USD 39.5 billion in 2024 to an impressive USD 59.4 billion by 2034. This growth is attributed to increasing innovations in technology and the rising production of smart devices that require efficient and reliable connectivity solutions. As manufacturers strive to streamline production processes and enhance device performance, pin header sockets will continue to play a pivotal role in shaping the dynamics of the electronics manufacturing landscape.