In today's rapidly evolving electronics landscape, the choice of components can significantly impact the success of a project, particularly when it comes to connecting devices. Male header pins play a crucial role in establishing reliable connections between various circuit boards and components. According to a recent industry report by MarketsandMarkets, the global connector market is projected to reach $90.7 billion by 2025, driven largely by the increasing demand for electronic devices across sectors such as automotive, telecommunications, and consumer electronics. Given the vast array of options available, selecting the right male header pins not only enhances performance and durability but also ensures seamless integration into your designs. This ultimate guide aims to navigate through the essential criteria and top types of male header pins, empowering project developers to make informed decisions that align with their technical needs and project goals.

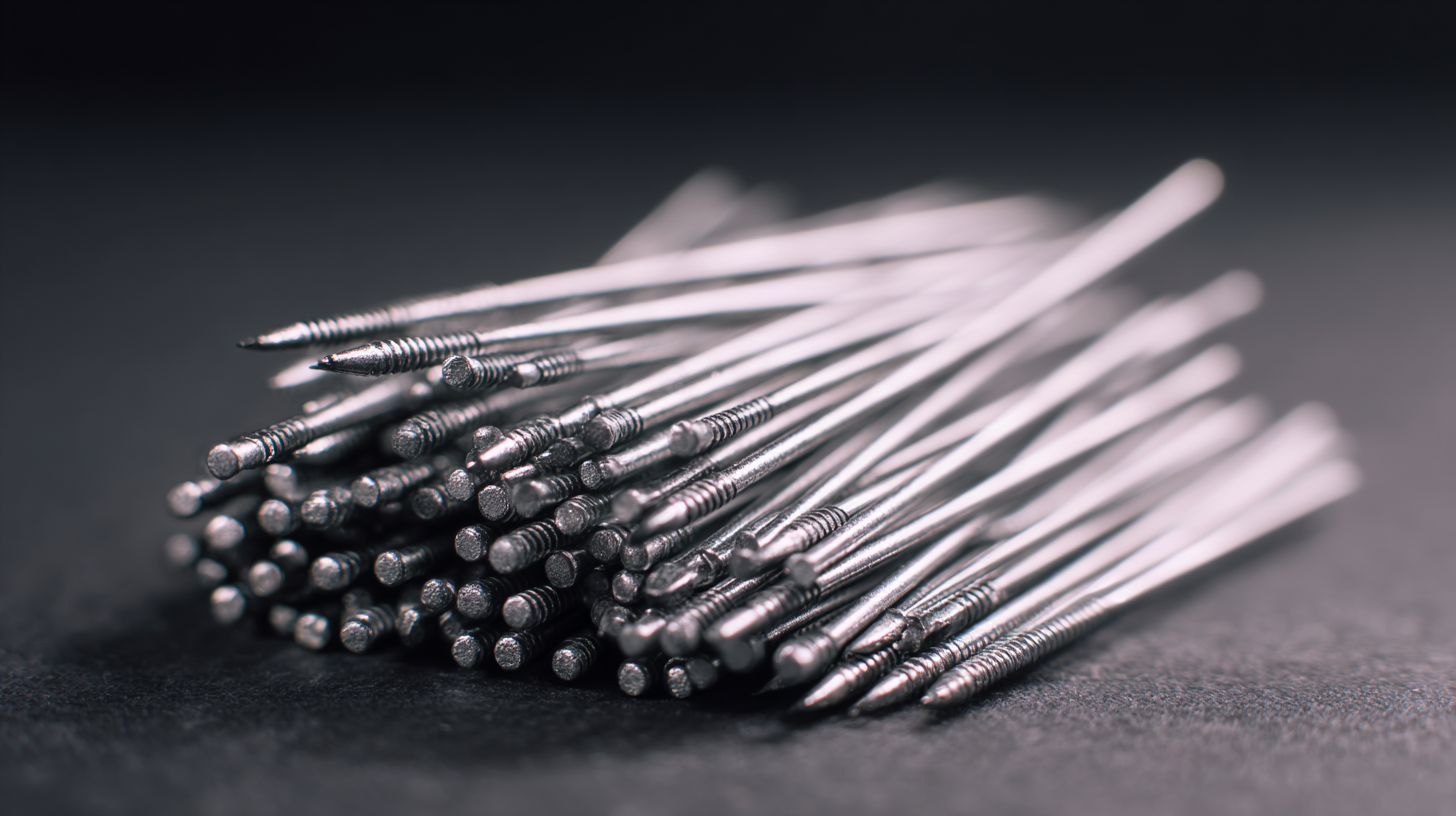

When selecting male header pins for your projects in 2025, understanding the various types and their specific applications is crucial. Male header pins come in different configurations, including standard pin headers, stackable pin headers, and right-angle headers. Standard pin headers are ideal for general applications, providing a secure connection for PCB designs. On the other hand, stackable headers allow for additional layers of components, making them perfect for projects requiring vertical integration, such as multi-layered circuit boards.

In addition to their physical configurations, different male header pins offer varying pin counts and spacing, which should be aligned with your project's requirement. For prototype applications, consider using male header pins with longer pins for easier insertion and removal. In contrast, applications demanding a compact design may benefit from shorter pins or low-profile headers. Moreover, the materials and plating of the pins—like gold plating for enhanced conductivity—can significantly influence their performance and durability, particularly in environments with higher wear and tear. Understanding these types and applications ensures you choose the best male header pins suited to your innovative projects in 2025.

When selecting male header pins for your projects, understanding the key factors can make all the difference in performance and reliability. One of the most important considerations is the pin configuration. Ensure the pin arrangement fits your project's design and connectivity needs. Common configurations include single, double, and multi-row headers, each serving different purposes based on the required space and electrical connections.

Tip: Always double-check the pin pitch before making a purchase. The standard pitch for male header pins is usually 2.54mm (0.1 inch), but variants exist. Using pins with the wrong pitch can lead to misalignment and connection issues.

Another crucial aspect is the material and plating of the pins. Look for headers made of high-quality metals like brass or phosphor bronze, as these materials ensure better conductivity and resistance to corrosion. Additionally, consider the plating options—gold plating provides excellent conductivity and prevents oxidation, making it ideal for high-frequency applications.

Tip: For projects exposed to high temperatures or harsh environments, opt for headers with a high-temperature rating to ensure durability and performance throughout their lifespan.

| Pin Type | Pin Count | Pitch (mm) | Material | Operating Temperature (°C) | Ideal Applications |

|---|---|---|---|---|---|

| Standard Male Headers | 2 to 40 | 2.54 | Brass with Nickel Plating | -40 to 105 | General PCB Connections |

| Low Profile Male Headers | 2 to 20 | 1.27 | Tin-Plated Brass | -40 to 85 | Space-Constrained Applications |

| Right Angle Male Headers | 2 to 40 | 2.54 | Bronze Alloy | -30 to 105 | Board-to-Board Connections |

| Stackable Male Headers | 2 to 20 | 2.54 | Gold-Plated Copper | -40 to 125 | Use in Daisy-Chain Connections |

In 2025, the world of male header pins is experiencing a significant transformation driven by innovative designs and advanced materials. As technology evolves, there is an increasing demand for connectors that not only offer enhanced performance but also embody ruggedness and miniaturization. This means that manufacturers are focusing on creating connectors that withstand harsh conditions while being compact enough to fit into ever-tightening spaces within electronic assemblies. Innovative design methodologies are at the forefront, allowing for the development of connectors that can optimize vehicle designs and other applications requiring durability and precision.

Furthermore, the rise of specialized design tools, like cable harness design software, is streamlining the development process for custom connectors and cables. These tools empower engineers and designers to bring their visions to life efficiently while ensuring compatibility with existing technologies. As we look towards the future, it's clear that the male header pin market will continue to grow, propelled by the integration of smarter, more sustainable manufacturing processes and an emphasis on adaptability in design. This evolution is not just about meeting today's standards but setting the stage for what’s possible in connector technology moving forward.

When integrating male header pins into your electronic projects, it’s essential to prioritize connection reliability and ease of use. Start by selecting high-quality male header pins that fit your project's specifications, including pin spacing and length. Opt for pins made from durable materials, like tin-plated copper, which ensure better conductivity and longevity. It's also useful to consider the density of the pins—higher densities allow for a more compact design, which can be particularly beneficial in space-constrained applications.

Once you've chosen the right pins, proper placement and soldering techniques are crucial for optimal performance. Ensure that the header pins are correctly aligned with your circuit board to prevent misconnection. When soldering, use the right temperature to avoid damaging the components. Additionally, it’s advisable to use a solder wick or vacuum pump to clean up any excess solder for a clean and reliable joint. Lastly, consider adding appropriate strain relief mechanisms to your wiring, as this can enhance the longevity of the connections by minimizing stress on the pins during use. These best practices will not only help you achieve better results but also make your projects more robust and reliable.

In the rapidly evolving landscape of technology, male header pins are becoming essential components in various applications, from consumer electronics to automotive systems. According to a recent market analysis by Grand View Research, the global connectors market size is projected to reach $76.73 billion by 2027, with a significant portion attributed to the increasing demand for compact and efficient electronic devices. This growth can be linked to the miniaturization trend, where smaller, more powerful components necessitate reliable interconnections that male header pins deliver.

When selecting male header pins for your projects, it's crucial to stay ahead of the curve. One future trend involves the integration of smart technologies into connectors, allowing them to perform diagnostic functions. For example, header pins equipped with sensor capabilities can monitor electrical performance, helping engineers catch issues before they escalate.

Tip: Always consider the pin configuration and material. A well-chosen gold-plated copper pin can enhance corrosion resistance, ensuring longevity in your designs.

Moreover, the shift towards automation and IoT devices necessitates higher durability and reliability from header pins. Manufacturers are innovating by using advanced materials and designs to withstand more demanding environments.

Tip: Opt for headers with locking mechanisms if your application entails movement or vibration, as this feature helps maintain secure connections.