When it comes to electronic components, the 2mm Pin Header Socket stands out as a critical element in establishing reliable connections within various applications, from consumer electronics to industrial machinery. As globalization continues to shape the manufacturing landscape, understanding export certification becomes increasingly vital for businesses looking to source or produce these components.

In this blog, we will delve into the essential aspects of navigating compliance when selecting a manufacturer for 2mm Pin Header Sockets. We will provide insights on how to identify reputable manufacturers through a comparison of their certifications, quality assurance practices, and adherence to international standards. By equipping yourself with knowledge about export certification, you can make informed decisions that enhance product reliability and ensure compliance in global markets.

In the realm of global trade, export certification plays a critical role, particularly for specialized components like the 2mm pin header socket. These products often find applications in various industries, from consumer electronics to automotive manufacturing. Understanding the nuances of export certification not only ensures compliance with international regulations but also enhances market access. As more countries enforce strict quality and safety standards, it becomes imperative for exporters to grasp the significance of certification processes that validate their products’ compliance.

When navigating the complexities of export certification, one key tip is to stay informed about the specific regulations pertinent to your target market. Different regions may require distinct certifications, and staying updated can prevent costly delays. Another vital aspect is collaborating with a knowledgeable certification body. Engaging experts can facilitate a smoother certification process, as they offer insights into necessary documentation and testing requirements that align with international standards.

Lastly, investing in comprehensive quality management systems can be beneficial. Implementing these systems not only streamlines compliance efforts but also enhances product reliability, which is a fundamental factor in gaining consumer trust. With these strategies in place, companies can effectively navigate the export certification landscape and gain a competitive edge in the global marketplace.

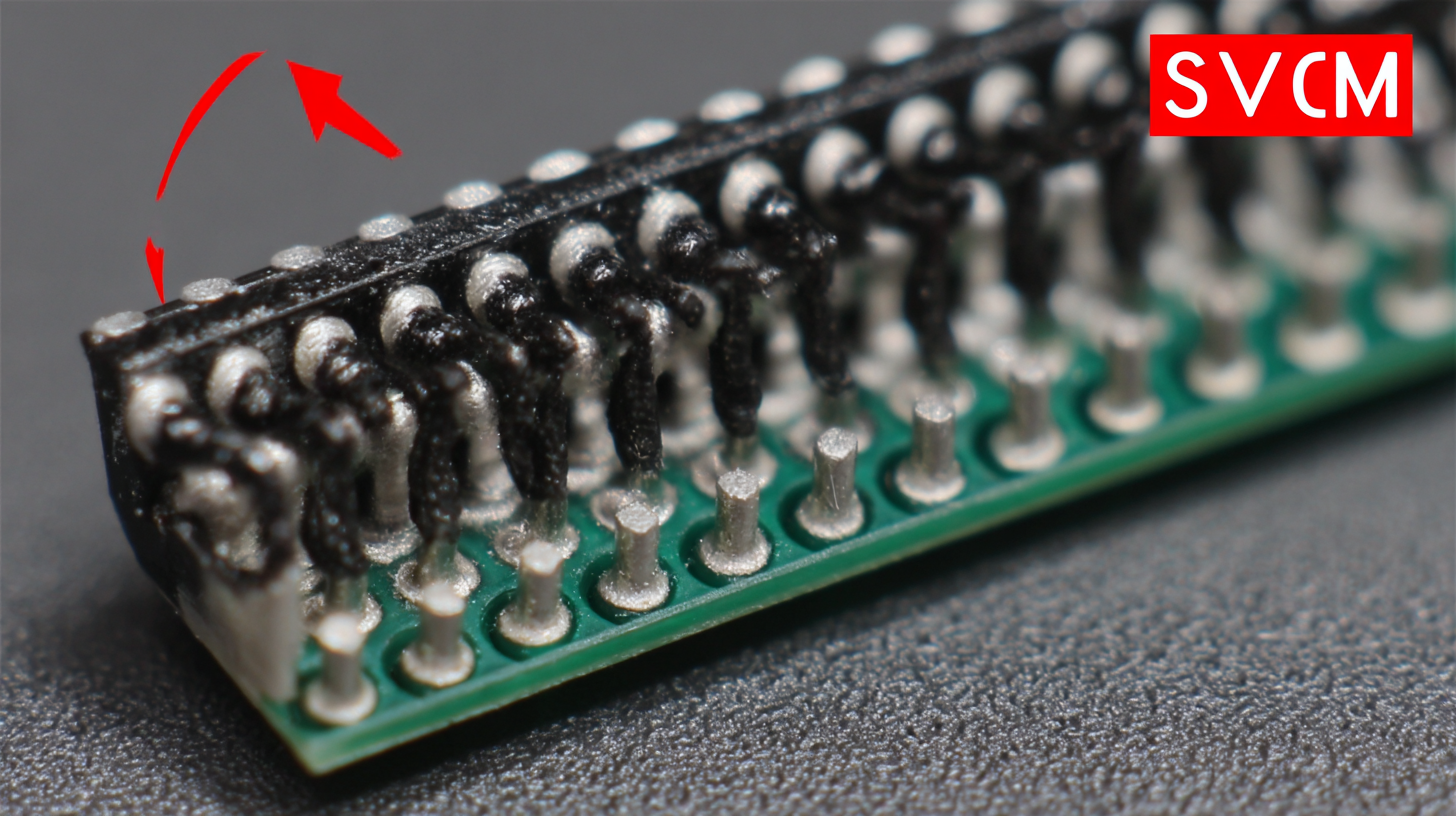

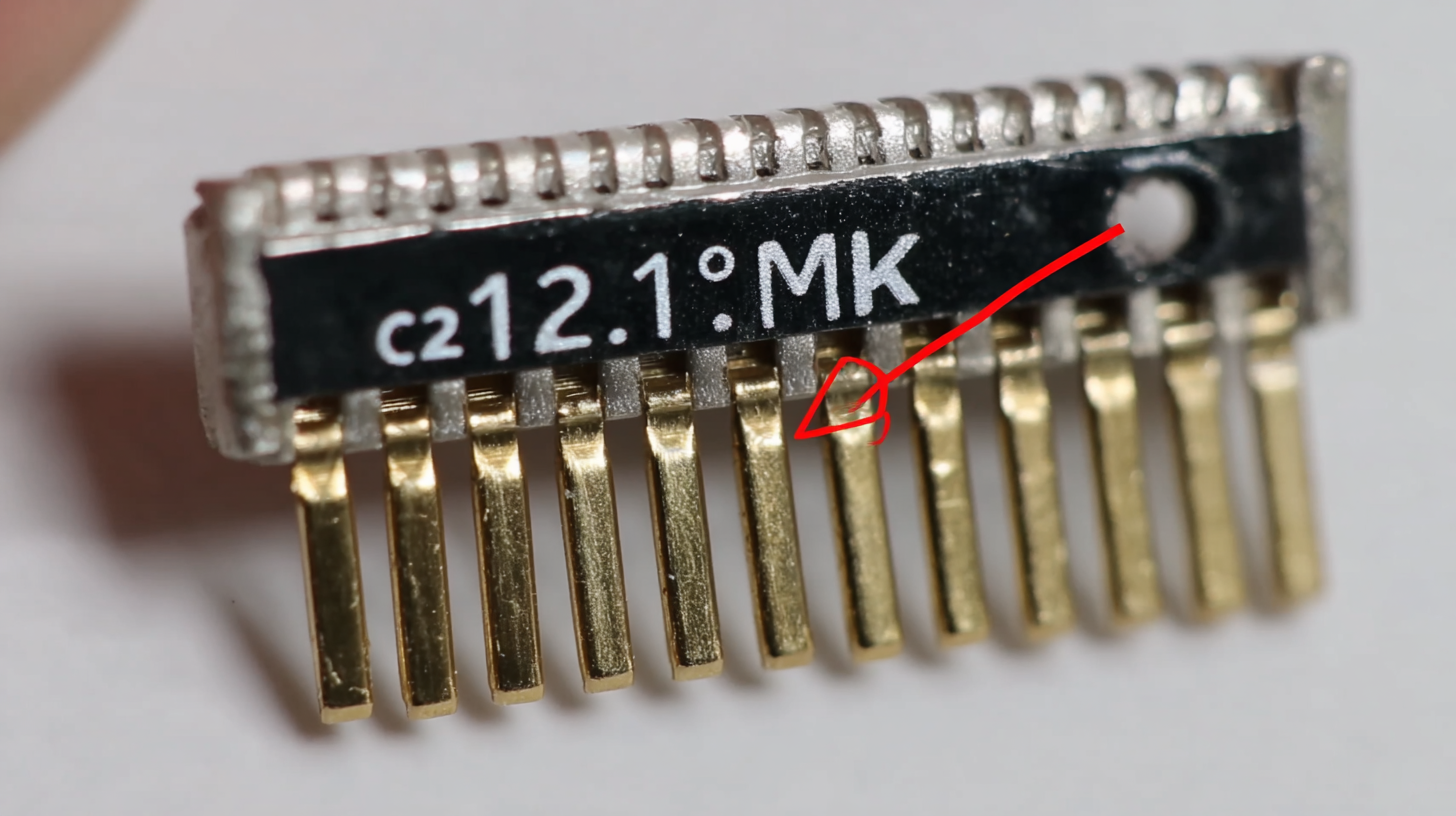

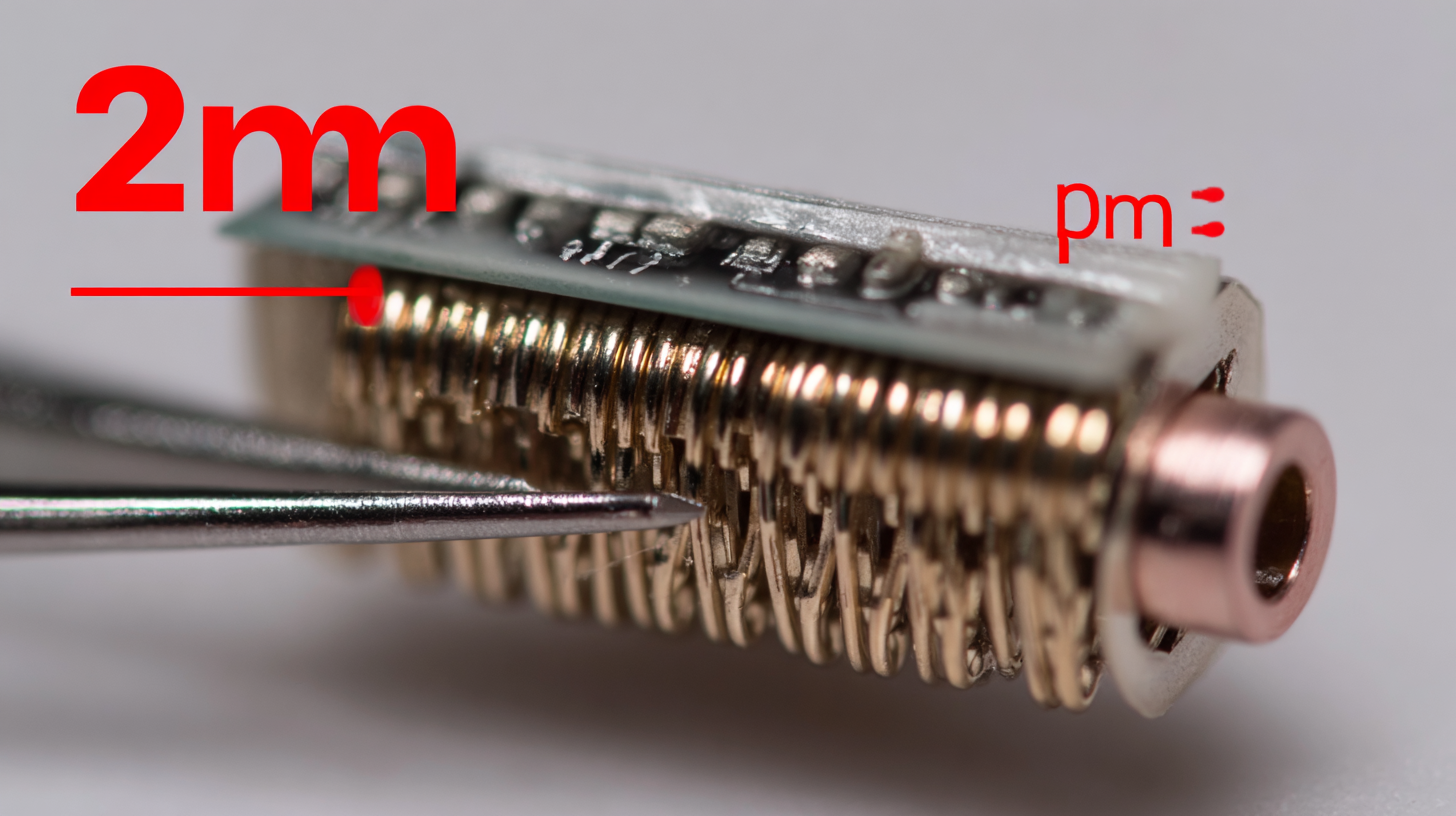

Navigating compliance regulations for electronic components, particularly for 2mm pin header sockets, is crucial for manufacturers looking to thrive in the competitive board-to-board connectors market. According to recent industry reports, the board-to-board connectors market is witnessing significant growth, driven by demand across various sectors such as consumer electronics, industrial automation, and telecommunications. For instance, connectors designed to handle high-speed signals, such as 28Gbit/s NRZ signals in a compact 2mm form factor, have become increasingly important in meeting the performance needs of modern devices.

When dealing with export certification for 2mm pin header sockets, it's essential to understand the key compliance regulations that apply, which can vary across regions. Standards set by organizations such as IEC and UL dictate safety and reliability benchmarks that must be met. Manufacturers should ensure that their products undergo thorough testing and certification processes to comply with these regulations, enhancing their marketability and reducing the risk of compliance issues.

**Tips:** Ensure that your products are tested against the latest compliance standards early in the design phase to avoid costly reworks. Additionally, maintain clear documentation of all certification processes, as this will facilitate smoother navigation through export regulations and bolster buyer confidence. Finally, adopting best practices in quality management can lead to improved product reliability and compliance, ultimately positioning your products favorably in the marketplace.

Navigating the export certification process for products like the 2mm pin header socket can seem daunting, but with the right approach, you can ensure both quality and compliance. The first step is to familiarize yourself with the specific regulations that apply to your product in the target market. Different countries have varying standards for electronics, so understanding these requirements upfront can save you time and resources. Engage with local regulatory bodies and industry associations to get insights into compliance essentials.

**Tips:** Always keep documentation organized. Create a checklist of required certifications and permits, and ensure that all your product specifications align with these requirements. This will facilitate a smoother review and approval process.

Next, consider working with a third-party certification body. They can help you navigate complex compliance issues and provide guidance on testing protocols necessary for export. Their expertise can be invaluable in addressing potential loopholes and ensuring your 2mm pin header socket meets international safety and performance standards.

**Tips:** Invest time in building relationships with certification professionals who can offer tailored advice based on your specific product and target market, which can significantly streamline the compliance process.

Quality assurance plays a pivotal role in the global success of China's 2mm pin header sockets. As international markets become increasingly competitive, ensuring that these components meet stringent quality standards is essential for manufacturers seeking to establish credibility and gain a foothold abroad. Quality assurance processes not only reduce the risk of defects and failures but also enhance customer satisfaction, fostering long-term relationships with clients. Heightened quality control measures can differentiate a company’s products in a crowded marketplace, ultimately impacting their bottom line.

Tips for ensuring quality in production include implementing robust testing protocols throughout the manufacturing process. This could involve regular inspections at multiple stages, from raw material sourcing to final assembly. Additionally, it is beneficial to invest in staff training to promote a culture of quality adherence among workers. Another effective strategy is to adopt internationally recognized quality management systems, such as ISO 9001, which can bolster trust and provide an edge in attracting overseas buyers.

Furthermore, communication with potential clients about the quality assurance processes in place can enhance transparency and build confidence. Providing detailed documentation of compliance and inspection results reassures customers that the products they are purchasing meet their quality expectations. By prioritizing quality assurance, manufacturers of China's 2mm pin header sockets can navigate compliance challenges and achieve greater success in global markets.

| Certification Type | Description | Compliance Requirements | Impact on Export | Quality Assurance Measures |

|---|---|---|---|---|

| CE Marking | Indicates compliance with EU safety, health, and environmental protection standards. | Product testing, technical documentation, and risk assessment. | Enhances product acceptance in European markets. | Regular product audits and third-party testing. |

| RoHS Compliance | Regulates hazardous substances in electrical and electronic equipment. | Materials testing for restricted substances. | Increases marketability in regions with stringent regulations. | Supplier management and material declaration. |

| UL Certification | Confirms products meet specific safety standards for the U.S. market. | Conducting safety testing and inspections. | Builds consumer trust and expands market access. | Implementation of safety management systems. |

| ISO 9001 | International standard for quality management systems. | Quality control processes and continual improvement. | Enhances operational efficiency and customer satisfaction. | Regular internal audits and management reviews. |

The growing demand for certified 2mm pin header sockets in international markets is closely tied to the trends within the board-to-board connectors sector. As industries such as consumer electronics, industrial automation, and telecommunications expand, the need for reliable connectors that meet stringent compliance standards becomes increasingly critical. Export certification not only facilitates smoother cross-border trade but also ensures that manufacturers can confidently meet the expectations of global consumers.

Recent insights into the market trends suggest that the board-to-board connectors landscape is evolving, with specific emphasis on pin headers and sockets. As companies seek to innovate and improve product performance, certified components will play a pivotal role in their supply chains. Adhering to export certification guidelines empowers manufacturers to enhance their competitiveness in the international arena, making certified 2mm pin header sockets not just a choice but a necessity in markets that prioritize quality and reliability.