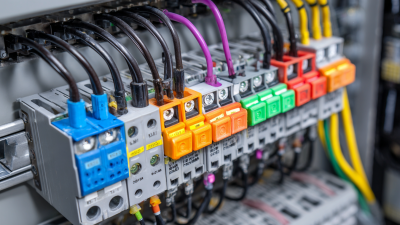

In the world of industrial automation, selecting the right PLC connector is crucial for ensuring reliable communication and power supply between devices. With a myriad of options available, choosing the optimal PLC connector that aligns with your specific industrial needs can seem daunting. Factors such as the connector's type, durability, compatibility, and environmental resistance play a significant role in its performance and longevity. This blog aims to provide you with five essential tips to navigate the complexities of PLC connector selection, empowering you to make informed decisions that enhance the efficiency and safety of your industrial operations. Whether you are a seasoned professional or new to the field, understanding the key aspects of PLC connectors will ultimately contribute to the seamless integration of your automated systems.

When choosing the right PLC connector for your industrial applications, it's crucial to understand the different types available on the market. PLC connectors serve as the vital link between various components of industrial automation systems, ensuring reliable communication and power transmission. As the global PLC splitter chip market is anticipated to grow significantly, with a projected increase from $0.2 billion in 2024 to $0.9 billion by 2033 at a CAGR of around 15.5%, understanding these connectors becomes ever more essential.

One key tip is to consider the compatibility of connectors with existing equipment and systems. This ensures seamless integration and reliable operation. Additionally, prioritize connectors that offer robust durability and resistance to harsh environmental conditions, as industrial settings often expose components to extreme temperatures, dust, and moisture. Lastly, evaluate the ease of installation and maintenance, as user-friendly connectors can significantly reduce downtime and enhance operational efficiency in your organization.

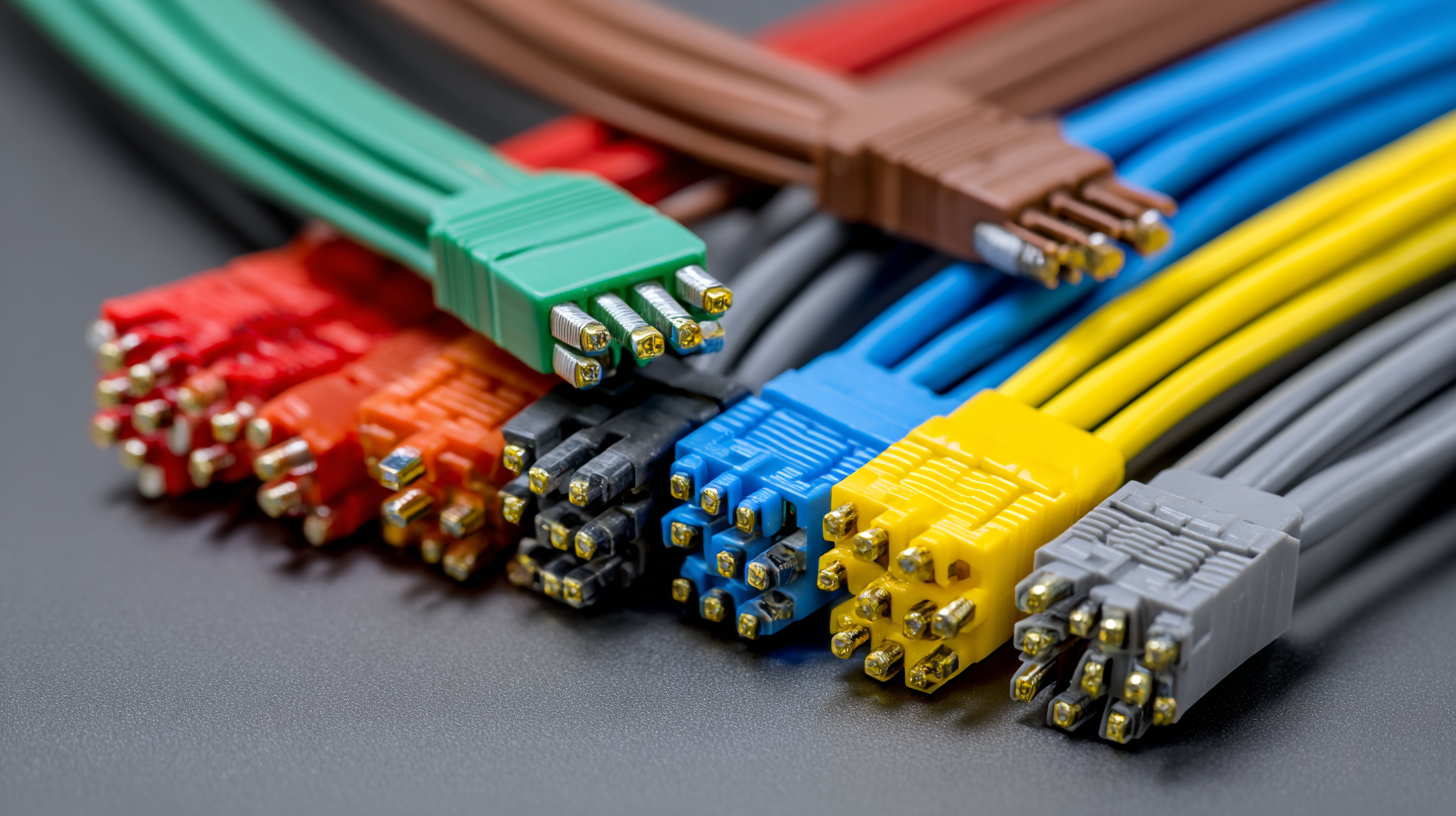

| Connector Type | Pin Count | Appropriate Application | Temperature Rating | IP Rating |

|---|---|---|---|---|

| Circular Connector | 5, 7, 9, 12 | Sensor Connections | -20°C to 85°C | IP67 |

| D-sub Connector | 9, 15, 25 | Computer Interface | -40°C to 100°C | IP54 |

| Ruggedized Connector | 12, 16, 24 | Outdoor and Harsh Environments | -40°C to 125°C | IP68 |

| Modular Connector | 8, 16, 32 | Modular System Applications | -30°C to 85°C | IP65 |

| Flat Ribbon Connector | 20, 28, 50 | Control Panel Wiring | -20°C to 70°C | IP20 |

When selecting a PLC connector for industrial applications, several key factors should be taken into account to ensure optimum performance and reliability. First, it’s crucial to consider the environmental conditions in which the connectors will operate. Factors such as temperature fluctuations, humidity, and exposure to dust or chemicals can significantly affect the longevity and functionality of the connectors. Choosing industrial-grade connectors designed to withstand harsh environments will enhance durability and reduce maintenance needs.

Another important aspect is the connector’s compatibility with your PLC equipment. Different PLC systems have specific requirements regarding pin configurations, sizes, and electrical ratings. Ensuring that the connector matches these specifications is vital for seamless integration and operation. Additionally, evaluate the ease of installation and maintenance; connectors that are user-friendly and support quick connections can save valuable time during setup and troubleshooting. By strategically assessing these factors, you can select the right PLC connector that meets your industrial needs efficiently.

When selecting a

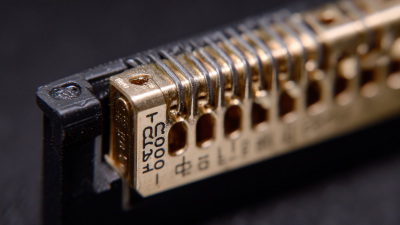

PLC connector for industrial applications, one of the most critical factors to consider is the

environmental conditions in which the connector will operate. The performance and longevity of a PLC connector depend heavily on its ability to withstand specific environmental stresses, including temperature fluctuations, humidity, dust, and exposure to chemicals. For instance, connectors used in high-temperature areas or humid environments must be designed with insulation materials that can handle extreme conditions without degrading or becoming ineffective over time.

Additionally, the

IP (Ingress Protection) rating of a connector should be assessed to ensure it meets the necessary standards for dust and moisture exposure. Connectors designed with higher IP ratings are typically suitable for harsh settings, where the likelihood of contamination or damage is greater. Furthermore, understanding the mechanical stresses that may be present—such as vibrations or physical impacts—can guide the selection of robust connectors that maintain reliable connections despite challenging industrial environments. Prioritizing these environmental factors not only enhances the performance of your PLC systems but also minimizes maintenance costs and downtime in the long run.

When selecting the right PLC connector for your industrial applications, evaluating compatibility with existing systems and components is critical. A recent industry report indicates that nearly 70% of integration issues arise from mismatched connectors and interfaces in PLC systems. Therefore, ensuring that your chosen connector aligns with your current hardware can significantly reduce downtime and maintenance costs.

One essential tip is to thoroughly check the pin configuration and electrical specifications. Different manufacturers may have varying standards, and using a connector that doesn't match your PLC's pin layout can lead to operational failures. Additionally, consider the environmental factors such as temperature and humidity ratings that are compatible with your systems. According to another study, inappropriate thermal ratings can reduce a connector's lifespan by 50%, leading to increased operational costs.

Furthermore, it's wise to verify the connector's certification and compliance with industry standards, such as those set by IEC and UL. This compliance not only assures quality but also ensures smoother integration into your existing systems. Selecting a connector with a proven track record within your industry can guarantee performance reliability and longevity, thus safeguarding your investment in automation technology.

When selecting the right PLC connector for industrial applications, balancing budget constraints with performance requirements is crucial. According to industry reports, a significant 60% of manufacturers prioritize cost-effectiveness without compromising quality, particularly for connectors that operate in demanding environments. Investing in quality connectors can lead to enhanced system reliability, reducing the likelihood of costly downtime and maintenance interruptions.

In the current market, achieving an optimal mix of cost and performance has never been more achievable. For instance, comparative studies show that mid-range PLC connectors often deliver 80% of the performance of high-end models at a fraction of the cost. By leveraging data on connector durability and performance metrics, manufacturers can make informed decisions that meet their operational needs while adhering to budget constraints. This strategic approach not only enhances the efficiency of industrial systems but also ensures that businesses receive the best return on their investment.