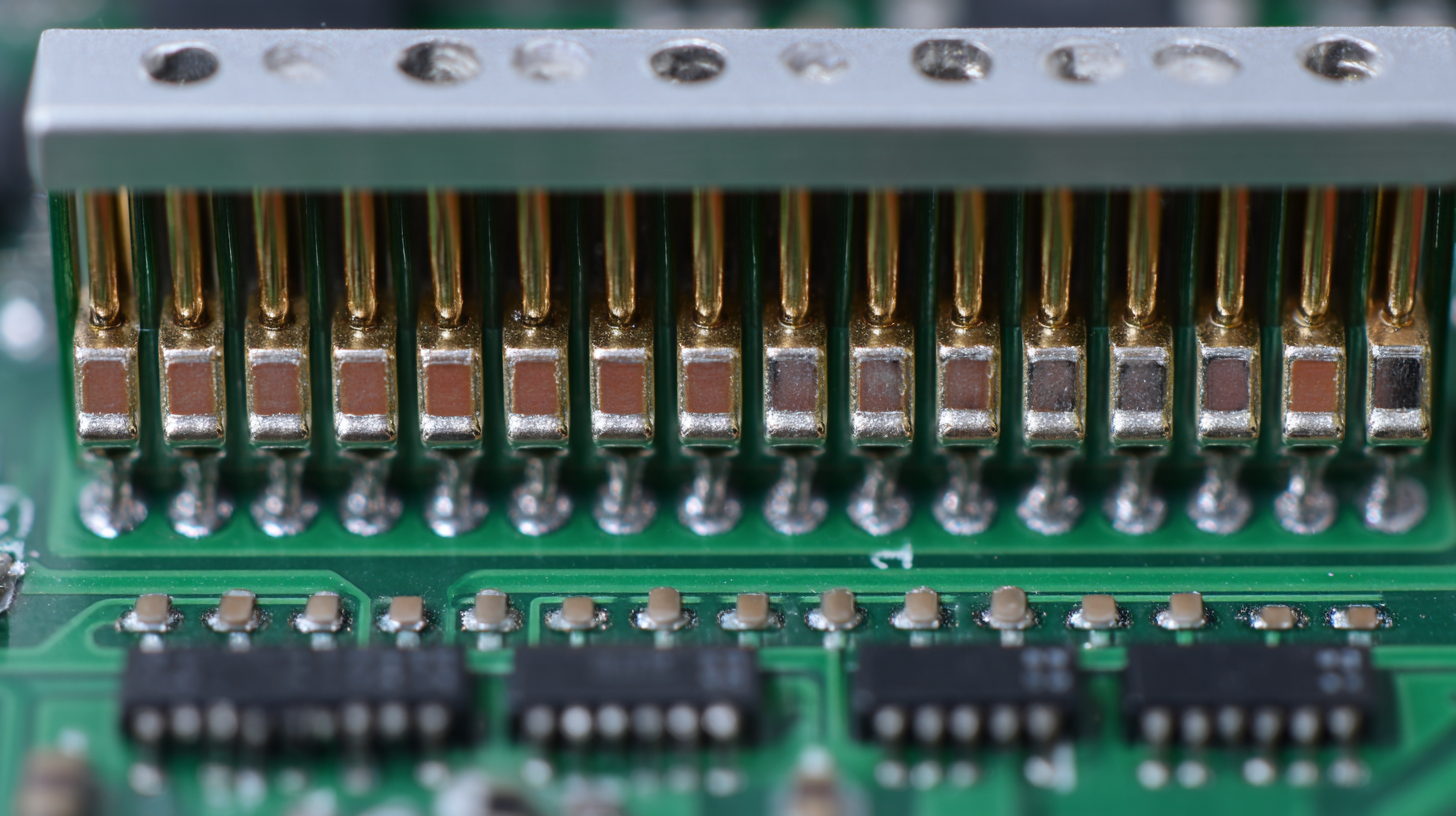

In today's rapidly evolving technology landscape, finding ways to enhance efficiency and performance is paramount for manufacturers and developers alike. One pivotal component that plays a crucial role in achieving this goal is the Socket Pin Header. These connectors provide a reliable interface for electrical signals, ensuring seamless communication between various electronic components. The advantages of utilizing high-quality Socket Pin Headers extend beyond mere connectivity; they encompass aspects such as ease of assembly, versatility in design, and improved durability, which are essential in a world demanding high-performance solutions.

Additionally, with the industry's focus on import and export certifications, understanding the best practices for incorporating these components can significantly impact product development and operational success. In this blog, we will explore how embracing top-notch Socket Pin Headers can lead to a breakthrough in operational efficiency while navigating the complexities of certifications in the ever-growing digital market.

Socket pin headers are essential components in modern electronics, providing a reliable means of connecting various board elements. As technology advances, the specifications for processors have become increasingly variable, requiring adaptable solutions for motherboard designs. The emergence of dual-use motherboards, such as those supporting Socket 370 and Slot 1, highlights the importance of versatile connectivity options. These innovations not only enhance compatibility but also facilitate easier upgrades for personal computers, ensuring that users can keep pace with evolving hardware requirements.

Socket pin headers are essential components in modern electronics, providing a reliable means of connecting various board elements. As technology advances, the specifications for processors have become increasingly variable, requiring adaptable solutions for motherboard designs. The emergence of dual-use motherboards, such as those supporting Socket 370 and Slot 1, highlights the importance of versatile connectivity options. These innovations not only enhance compatibility but also facilitate easier upgrades for personal computers, ensuring that users can keep pace with evolving hardware requirements.

When working with socket pin headers, it's important to keep a few tips in mind. First, always verify the pin count and configuration to ensure proper alignment and connection. Mismatched configurations can lead to performance issues or permanent damage to components. Second, consider using high-quality socket pin headers that provide better durability and resistance to wear, especially in applications where frequent connections and disconnections occur. Lastly, regular maintenance and cleaning of socket pin headers can help prolong their lifespan, ensuring optimal performance in your electronic devices.

In the rapidly evolving landscape of technology, the performance metrics of high-quality socket pin headers are paramount for optimal system efficiency. Socket pin headers serve as pivotal connection points, influencing data transfer speeds and overall system reliability. According to industry reports, utilizing superior socket pin headers can enhance signal integrity and reduce latency, particularly in demanding applications like gaming and high-performance computing. For instance, systems that incorporate advanced pin header designs can achieve data transfer rates exceeding 10 Gbps, a crucial factor when handling the increasing bandwidth requirements of modern processors.

Moreover, the integration of improved socket pin headers plays a vital role in the thermal management of various hardware components. Enhanced designs equip motherboards with better power delivery systems, allowing for increased stability during intense workloads. A report from a recent motherboard analysis indicated that high-quality pin headers contribute significantly to reducing voltage ripple, thereby prolonging the lifespan of critical components. This is especially important for configurations equipped with high-thread count processors, where efficient power distribution can lead to noticeable performance gains. By prioritizing the implementation of top-tier socket pin headers, manufacturers can unlock unparalleled performance and reliability for gamers and professionals alike.

Socket pin headers are a critical component in modern manufacturing, offering significant advantages in enhancing efficiency and performance. These connectors facilitate better connectivity and simplify the assembly process, allowing manufacturers to streamline their operations. By employing socket pin headers, companies can reduce assembly time and minimize the chances of errors, leading to improved productivity and lower operational costs.

Tip: When integrating socket pin headers into your manufacturing processes, consider standardizing the sizes and pin configurations across different products. This not only simplifies inventory management but also speeds up the design phase, as engineers can work with a consistent set of components.

Moreover, the use of socket pin headers enhances the flexibility of manufacturing systems. They allow for quick modifications and repairs, enabling manufacturers to adapt to changing demands without incurring excessive downtime. This adaptability is crucial in today's fast-paced market where responsiveness is key to staying competitive.

Tip: Regularly review and optimize the layout of socket pin headers in your assemblies. A well-planned layout can further reduce assembly time and improve overall workflow efficiency.

| Feature | Advantage | Impact on Efficiency | Application Areas |

|---|---|---|---|

| Ease of Assembly | Reduces assembly time | Increases overall productivity | Consumer electronics, automotive |

| Space Efficiency | Compact design | Maximizes board space | Telecommunications, medical devices |

| Durability | Longer lifespan | Reduces replacement costs | Industrial controls, robotics |

| Electrical Reliability | Stable connections | Enhances performance consistency | Automotive, aerospace |

| Versatility | Compatible with various components | Adapts to diverse applications | Consumer products, machinery |

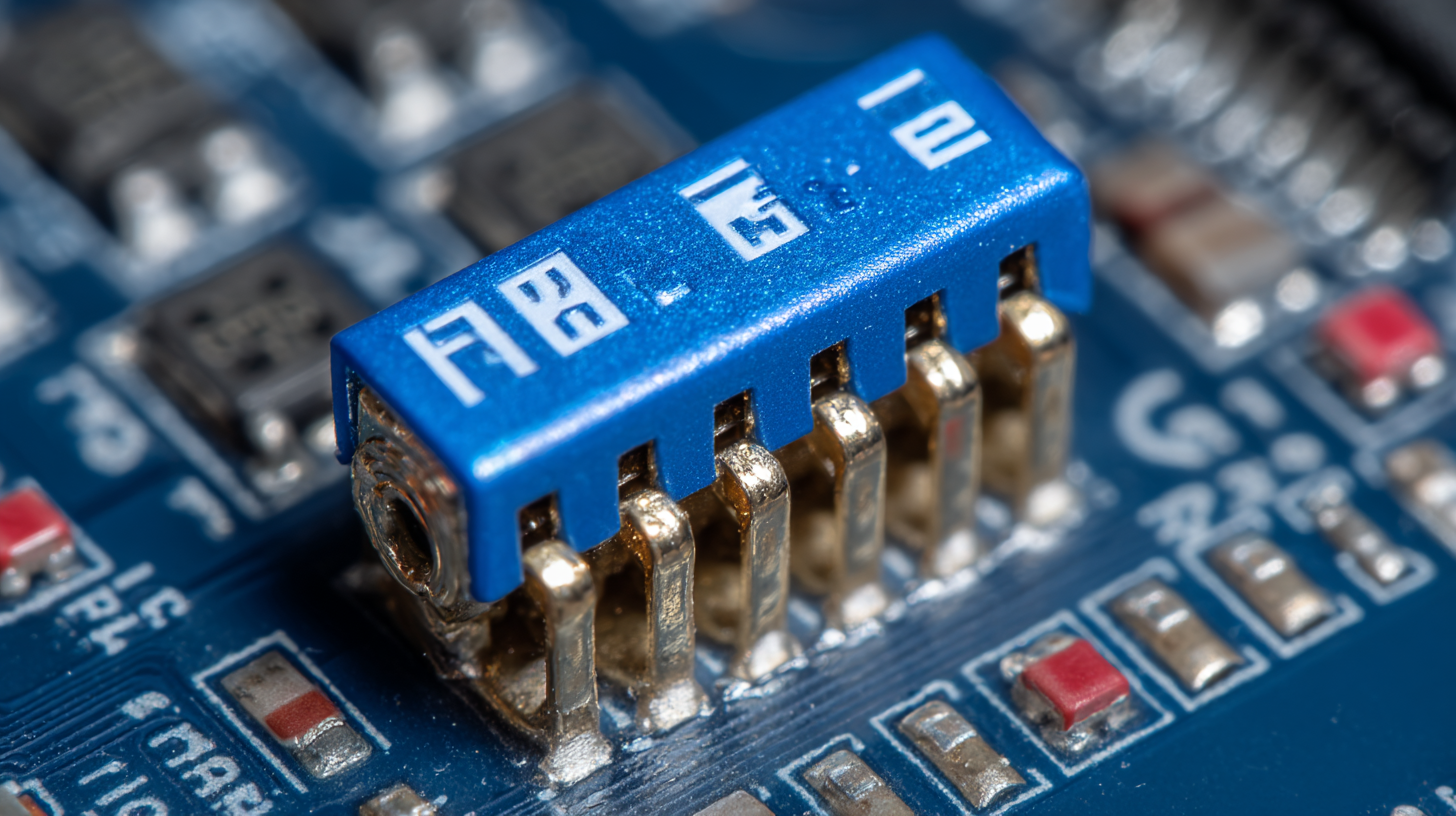

The choice between traditional and advanced socket pin headers significantly impacts both efficiency and product lifespan in electronic designs. Traditional socket pin headers often fall short in reliability and performance, typically leading to increased failure rates and shortened product lifespans. In contrast, advanced socket pin headers incorporate improved materials and design features. According to a recent industry report, devices utilizing advanced headers show a 30% reduction in connection failure rates and can extend total operational lifespan by up to 25%.

Tips for selecting the right socket pin header: Firstly, consider the application environment. For high-vibration or thermal cycling conditions, advanced headers are recommended. Additionally, pay attention to the gold plating thickness; a thicker layer reduces oxidation and enhances conductivity, which is crucial for maintaining performance over time. Lastly, always check the manufacturer’s specifications concerning maximum current and voltage. This not only safeguards your product's efficiency but also contributes to its durability.

Moreover, investments in quality materials and precision engineering in advanced socket pin headers not only boost performance but also promise long-term savings. A lifecycle cost analysis indicates savings of up to 40% in maintenance and replacements when using superior sockets. As designs evolve, migration to advanced socket pin headers becomes not just a choice but a necessity for ensuring both efficiency and longevity in electronic products.

The evolution of socket pin header technology is critical as the electronics industry continues to innovate. Future trends indicate that developments in connector design are being heavily influenced by the burgeoning electric vehicle market, which requires robust and versatile connections. According to industry reports, the PCB Connector Market is projected to reach USD 46.31 billion by 2034, reflecting the increasing demand for efficient and reliable connectors that meet the rigorous standards of modern automotive applications. This surge is not just limited to EVs but spans a wide array of electronic devices, highlighting the importance of adaptable and high-performance connection solutions.

Moreover, as manufacturers aim to meet emerging automotive demands, the focus is shifting towards designing connectors that are not only efficient but also capable of integrating advanced technologies such as smart features and IoT connectivity. The current landscape reveals a competitive push among companies to standardize connectors, which improves interoperability and facilitates seamless charging solutions for electric vehicles. As innovations continue to shape socket pin headers, their implications for electronics design will be profound, fostering a new era of connectivity that enhances both performance and user experience.

This chart illustrates the advantages of Socket Pin Headers based on five key dimensions: Signal Integrity, Cost Efficiency, Ease of Use, Design Flexibility, and Durability. Each advantage is rated on a scale from 0 to 100, showcasing their impact on electronics design.