Choosing the right Pin Header Socket is crucial for the success of your project. The global pin header socket market is projected to grow significantly, reaching $2.5 billion by 2025, as reported by industry analysts. This growth indicates the increasing demand for reliable and efficient electronic connections. It's vital to select components that can endure various conditions in applications ranging from automotive to consumer electronics.

Pin Header Sockets come in various sizes, configurations, and materials. This diversity can lead to confusion. For instance, using the wrong size can result in poor connectivity. Many engineers face the challenge of balancing functionality and cost. Often, they overlook the long-term implications of their choices. Selecting a durable socket could enhance the lifespan of your project, saving costs in future maintenance.

Furthermore, quality assurance standards play a significant role in your choice. Reports show that failure rates increase when inferior sockets are used. These failures can lead to project setbacks or recalls. Careful consideration of quality standards and specifications is essential. Ultimately, your selection can impact not just performance but also your reputation in the industry. Balancing these factors is indeed a tightrope walk.

Choosing the right pin header socket involves understanding its types and specifications. Pin header sockets come in various forms. They can be single-row or double-row. Also, they vary in pin counts from 2 to 40 pins or more. The layout and dimensions are essential for compatibility. These details often get overlooked during selection, leading to mismatched components.

The spacing between pins is another crucial specification. Standard spacings include 2.54mm and 1.27mm. Using the wrong spacing can result in assembly issues. It's vital to measure the board accurately. Take time to ensure dimensions match your PCB layout. Mistakes here can lead to costly redesigns.

Material matters too. Look for sockets made of durable plastic and reliable metal. This combination offers stability and good conductivity. While it may seem trivial, cheap materials can degrade over time. It's wise to reflect on the long-term impact of your choices. With pin header sockets, attention to detail enhances the overall quality of your project.

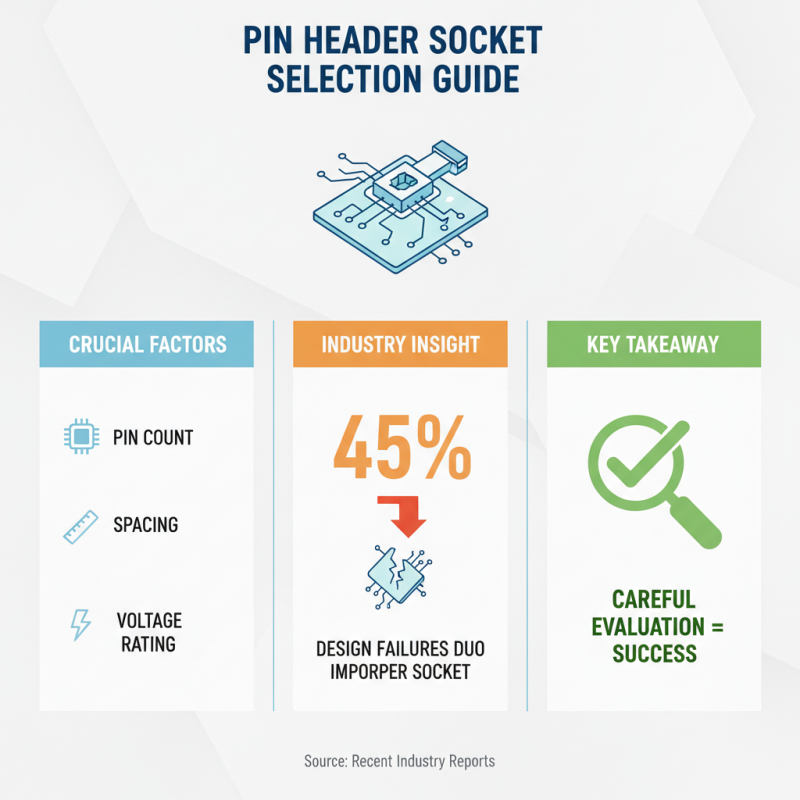

When selecting a pin header socket, understanding your project requirements is crucial. The right choice hinges on factors like pin count, spacing, and voltage ratings. Data from recent industry reports indicate that over 45% of design failures are due to improper socket selection. This figure underscores the need for careful evaluation.

Tip: Always determine the pin count early. This will narrow down your options significantly. Standard configurations include 2, 4, 8, or up to 64 pins. It's vital to match the socket to your PCB layout. Misalignment can cause project delays and added costs.

Consider the environment where the pin header will be used. If your project operates in extreme temperatures, you'll need sockets made from specific materials. About 30% of sockets fail due to thermal expansion issues. Sourcing sockets that meet your temperature criteria can prevent future headaches.

Tip: Check for specifications like current rating and insulation resistance. Choosing a socket that doesn't meet these needs can result in underperformance. Reflect on how your chosen socket interacts with other components in your design. Every small detail matters in the success of your project.

When selecting a pin header socket, material and durability are crucial factors. These components often encounter various environments, such as high temperatures and moisture. Choosing the right material can significantly impact performance. For example, a socket made from high-quality plastic can resist heat and wear over time. On the other hand, cheaper options may crack easily under stress.

Metal contacts play a role too. They must be durable enough to endure repeated insertions and removals. Not all metals are the same; some corrode faster than others when exposed to humidity. A corrosion-resistant alloy offers better longevity. This choice could prevent connection issues down the line, which can be frustrating.

It’s vital to be aware of your project's specific needs. Not evaluating these aspects might lead to unexpected failures. Consider how connectors will be used in real-life scenarios. It’s easy to overlook minor details, yet they can have significant effects. Rethinking your material choices could save time and resources. Be cautious, as the initial choice can impact performance in the long run.

Choosing the right pin header socket is crucial for project success. Compatibility with other components is often overlooked. Many projects fail due to mismatched sockets. A report from the Electronic Components Industry Association indicates that 40% of design errors stem from compatibility issues.

When selecting a pin header socket, consider the pitch size. Standard pitch sizes include 2.0mm, 2.54mm, and 1.27mm. Using the wrong pitch can lead to connection failures. For instance, a 2.0mm socket won’t fit a 2.54mm pin. This mismatch can disrupt signaling and power distribution. Measurement precision is vital.

Length also matters. A socket that is too long may not fit in compact designs. The height can cause clearance issues. Depending on your board's layout, this can lead to assembly problems. The tolerance levels in manufacturing play a role, too. Variations can affect the fit. Always assess your entire setup before making a final decision. Sometimes, it’s the little details that create the biggest headaches.

This bar chart represents the compatibility rating of various types of pin header sockets based on their standard characteristics. A higher rating indicates better compatibility with standard components in electronic projects.

When selecting a supplier for pin header sockets, it is vital to evaluate their reliability. Look for suppliers with solid reputations and positive reviews. A dependable supplier often has years of experience in the industry. This experience can translate to better product quality and customer service. Don't hesitate to ask for product samples. Testing them in your project can save future headaches.

Pricing options matter, too. Compare prices across several suppliers. However, be wary of too-good-to-be-true deals. They may indicate lower quality, which could compromise your project. Understand the pricing structure clearly. Some suppliers may charge extra for shipping, which can add to your overall costs.

Tips: Always check the minimum order quantities. Some suppliers require large minimum orders. This may not be ideal for small projects. Ensure their pricing model fits your project scale. Market trends can also affect pricing. Keep an eye on fluctuation to avoid budget issues. Consider the total cost of ownership, not just the upfront price. This can provide a more accurate picture of what you're paying.

| Parameter | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Pin Count | 2 | 4 | 10 |

| Pitch Size | 2.54mm | 1.27mm | 3.96mm |

| Material | Plastic | Metal | Composite |

| Temperature Rating | -40 to +85°C | -20 to +120°C | -55 to +150°C |

| Voltage Rating | 30V | 50V | 100V |

| Price Range per Unit | $0.10 | $0.15 | $0.25 |