In the ever-evolving landscape of electronics, the importance of selecting the right components cannot be overstated. Among these components, Male Header Pins stand out as critical elements that facilitate seamless connections in various electronic projects. As reported by industry experts, the global semiconductor market is projected to reach $1 trillion by 2025, highlighting the growing demand for reliable and efficient electronic components. Male Header Pins, essential for interfacing microcontrollers and other circuit boards, play a vital role in this development, representing a significant portion of the interconnect market.

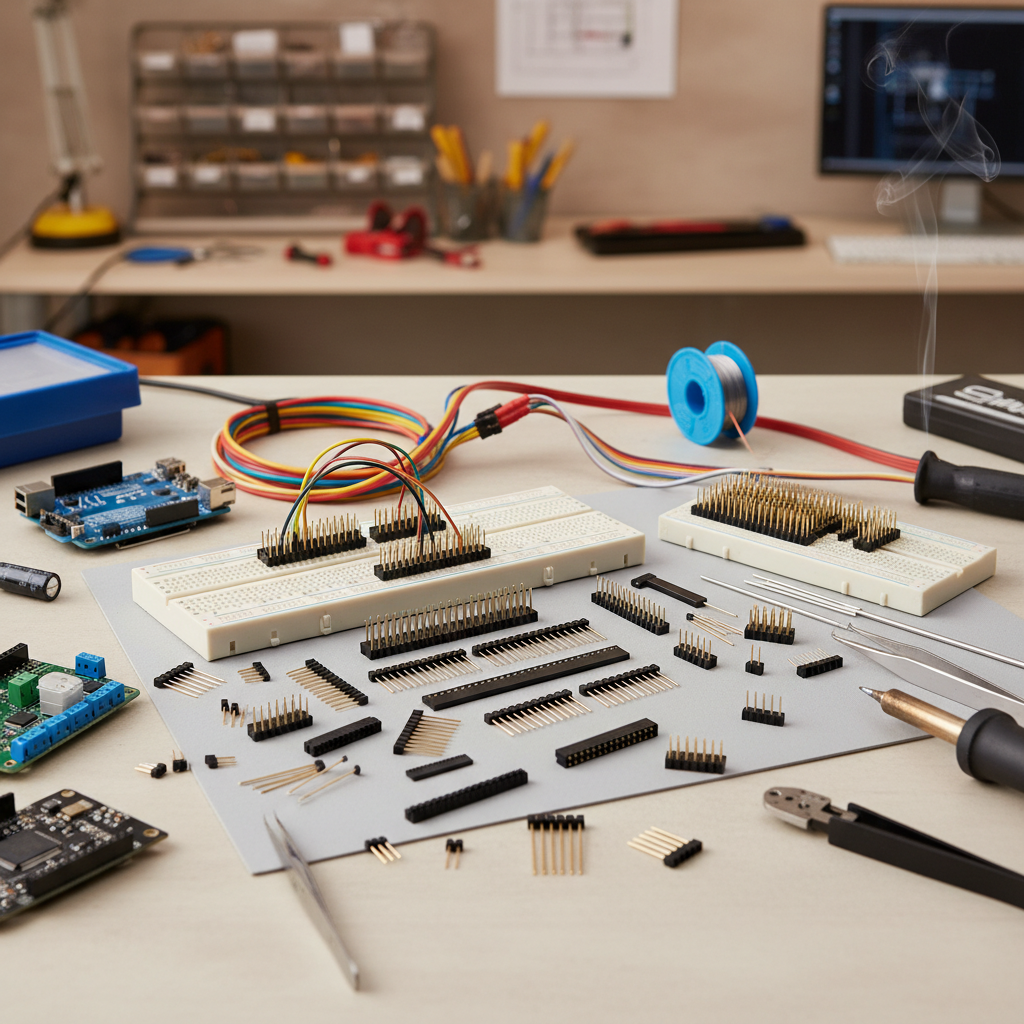

Choosing the best Male Header Pins for your specific electronics projects requires careful consideration of material, pitch, and durability. Various studies indicate that the right selection can enhance the performance and longevity of electronic devices, potentially reducing failure rates by as much as 30%. Furthermore, with advancements in technology and manufacturing processes, the variety of options available in the market has expanded, making it essential for hobbyists and professionals alike to stay informed. This comprehensive guide will explore the top five Male Header Pins of 2025, equipping you with the knowledge needed to make informed decisions for your upcoming projects.

When it comes to selecting male header pins for electronics projects, understanding their types and applications is crucial. Male header pins are primarily categorized into through-hole and surface-mount designs, with through-hole pins dominating in hobbyist and prototype applications due to ease of use and solderability. According to a report by the Electronics Components Industry Association (ECIA), the global demand for header pins is projected to grow by 4.3% annually, highlighting their importance in the expanding electronics market.

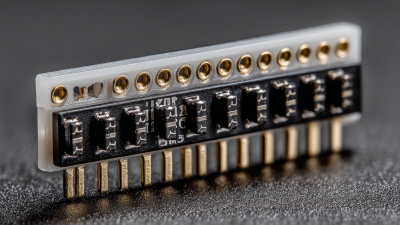

Different applications will dictate the specific type of male header pin required. For instance, in microcontroller applications, 2.54mm pitch header pins are often used for their compatibility with standard breadboards, allowing for easy prototyping. On the other hand, connectors for high-density applications are turning towards smaller pitches, such as 1.27mm, to save space while maintaining robust electrical connections. The suitability of various pins can significantly impact the performance and reliability of electronic assemblies, underscoring the importance of informed selection in the design process. This detailed understanding empowers engineers and hobbyists alike to choose the most appropriate components for their unique projects.

When selecting male header pins for your electronics projects, it’s crucial to consider several key specifications to ensure compatibility and performance. First, the pin pitch, which is the distance between the centers of two adjacent pins, is a fundamental measurement that affects how easily the headers can fit into your circuit board. The most common pitch sizes are 2.54mm (0.1 inches) and 1.27mm (0.05 inches), so choosing the right one depends on your specific application and the layout of the PCB.

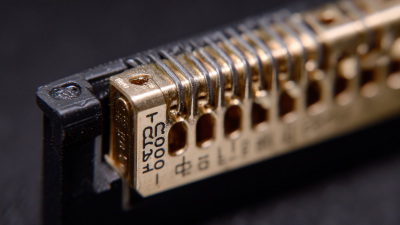

Another important factor is the material and plating of the pins. Typically, header pins are made from brass with gold or tin plating to enhance conductivity and resistance to corrosion. Gold plating, while more expensive, provides superior corrosion resistance and is ideal for applications that require a reliable connection over time. Additionally, consider the current and voltage ratings of the pins, as these specifications determine how much power the pins can safely handle, influencing the overall safety and longevity of your project. Selecting the right male header pins with these factors in mind will help ensure your electronic projects run smoothly and efficiently.

This chart illustrates key specifications to consider when choosing male header pins for electronics projects, highlighting essential attributes such as pin count, pin pitch, current rating, operating temperature, and material type.

When selecting male header pins for electronics projects, understanding the market landscape is crucial. A 2023 report from Future Market Insights highlights that the global connector market, which includes male header pins, is projected to exceed $80 billion by 2030, with a compound annual growth rate (CAGR) of 4.8%. This growth is driven by increasing demand in sectors like consumer electronics, automotive, and telecommunications.

Consequently, brands like Molex, TE Connectivity, and Amphenol have emerged as industry leaders, consistently investing in quality and innovation.

Molex, known for its robust and reliable pin designs, boasts a product range that fits various electronic applications. Their headers feature gold plating for better conductivity, which is essential for high-performance circuits. Conversely, TE Connectivity focuses on customization, with options tailored to unique project specifications, thus catering to both hobbyists and professionals.

Amphenol stands out with its competitive pricing strategies while maintaining high-quality standards. According to industry studies, 68% of engineers prioritize reliability over cost, indicating that brand reputation and pin durability are paramount considerations for successful electronic project outcomes.

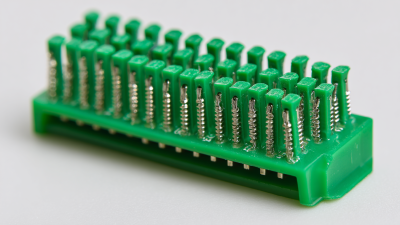

In recent years, the use of solderless male header pins has gained significant traction in the electronics prototyping industry. A report from TechNavio indicates that the global market for solderless connectors is projected to grow by over 6% annually through 2025. This shift can be attributed to the increasing demand for faster prototyping and the need for flexibility in design modifications. Solderless male header pins offer a quick and efficient way to connect components without the risks associated with soldering, such as overheating and desoldering errors.

Moreover, industry professionals have noted that solderless male header pins improve the reusability of prototypes, making them a cost-effective solution for engineers and designers. According to a survey conducted by the Electronics Industry Association, around 70% of engineers prefer using solderless connectors in their initial prototyping phases, highlighting a clear trend toward reduced labor costs and minimized assembly times. As prototyping becomes more integral to product development cycles, the adoption of solderless male header pins will likely continue to expand, reflecting a broader trend towards agile and efficient design methodologies in the electronics sector.

| Type | Pin Count | Length (mm) | Pitch (mm) | Material | Finish | Applications |

|---|---|---|---|---|---|---|

| Standard Male Header | 2-40 | 10-50 | 2.54 | Brass | Gold Plated | General Electronics |

| Solderless Male Header | 2-20 | 8-30 | 2.54 | Plastic & Copper | Tin Plated | Prototyping |

| Surface Mount Header | 2-32 | 5-25 | 1.27 | Brass | Nickel Plated | Compact Circuits |

| Dual Row Header | 2-40 | 10-50 | 2.54 | Brass | Gold Plated | Connectors |

When integrating male header pins into your electronic projects, there are several best practices to ensure reliability and efficiency. First and foremost, it's essential to choose the right pin spacing. Standard pin spacings include 2.54mm and 1.27mm, so always verify that your PCB design matches the size of the header pins you plan to use. This careful selection prevents issues related to improper fit or poor connections.

Tip: Always use a multi-meter to test continuity between your male header pins and corresponding components after soldering to avoid latent faults in your project.

Another critical aspect is the proper soldering technique. Ensure that you heat the joint sufficiently but avoid overheating to prevent damage to both the pins and the PCB. For a secure connection, apply solder from the opposite side of the pin after heating the pin and pad simultaneously.

Tip: Use flux to improve solder flow and reduce oxidation, which can lead to weak connections over time. Additionally, consider employing a jig or fixture to hold the pins in place during soldering to maintain alignment.