In the evolving landscape of electronics, the choice of interconnect solutions can significantly influence the success of a project. As leading expert in the field, Dr. Emily Chen, a renowned engineer specializing in interconnectivity, emphasizes, "The efficiency and reliability of a Board To Board Connector can elevate your project from concept to reality." With their unique ability to provide reliable connections between printed circuit boards (PCBs), Board To Board Connectors have emerged as an essential component in modern design practices across various industries.

The advantages of using Board To Board Connectors are manifold. They not only streamline the assembly process but also enhance scalability and versatility in design, making them an ideal choice for both prototyping and large-scale production. Analysts predict that as technology continues to advance, the demand for high-performance Board To Board Connectors will grow, driven by the increasing need for compact, efficient solutions in devices that require precision and durability. Thus, tapping into the potential of these connectors can yield significant long-term benefits for engineers and designers seeking to optimize their next project.

Board to board connectors have become essential in modern electronics, offering numerous advantages that cater to the evolving demands of the industry. According to a report by the Market Research Future, the global connector market is expected to grow at a compound annual growth rate (CAGR) of 5.3% between 2021 and 2027, driven primarily by the increasing demand for miniaturization and high-performance interconnects. This growth underscores the significance of board to board connectors, which facilitate space-saving designs while maintaining reliable electrical connections.

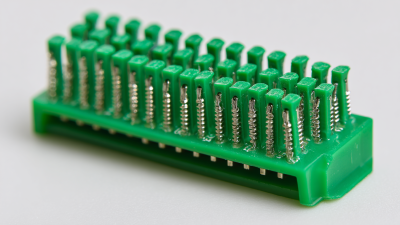

One of the significant benefits of board to board connectors is their ability to decrease assembly costs and improve design flexibility. These connectors allow for easy modular design, enabling manufacturers to develop and modify products quickly without extensive re-engineering. In addition, the adoption of advanced technologies, such as blind mate and zero insertion force (ZIF) designs, has further enhanced the reliability and efficiency of these connectors, making them ideal for applications in consumer electronics, telecommunications, and automotive sectors. The global demand for high-density interconnect solutions reflects these trends, with reports estimating that by 2025, the market for such connectors could reach over $15 billion, confirming the critical role they play in contemporary electronic systems.

Board to board connectors play a vital role in various industries, facilitating seamless communication between different printed circuit boards (PCBs). In the consumer electronics sector, these connectors are crucial for devices that require compact designs without sacrificing performance. They enable the interconnection of various components, such as displays, batteries, and audio modules, allowing for efficient power distribution and data transfer while optimizing space. As products become smaller and more sophisticated, the reliance on these connectors grows, driving innovation in their design and functionality.

In the automotive industry, board to board connectors contribute significantly to the advanced technology integrated into modern vehicles, including infotainment systems, safety features, and electric vehicle components. Their robust nature ensures reliable performance in the face of vibrations, temperature fluctuations, and moisture—challenges that are commonplace in automotive environments. Furthermore, the medical devices sector benefits from these connectors, where precision and reliability are paramount. Board to board connectors are used in imaging systems, patient monitoring equipment, and diagnostic devices, enabling high-speed data transfer and ensuring that critical medical information is transmitted accurately and swiftly.

When considering connector types for electronic projects,

board to board connectors stand out for their versatility

and performance. According to a report by Research and Markets,

the global market for connectors is expected to reach $105 billion

by 2025, with a significant portion attributed to board to board connectors. These connectors allow for

the seamless integration of two separate printed circuit boards (PCBs), offering benefits such as

reduced assembly time and improved reliability.

Their compact design enables higher pin counts within a smaller footprint, which is crucial in today's

miniaturized electronic devices.

In contrast, wire to board and cable connectors, while still widely used, typically present challenges

in assembly and space management. For instance, the connector types that rely on cables can introduce

additional points of failure and require more time for installation. According to a study by Allied Market

Research, the need for efficient space utilization in consumer electronics drives the demand for

board to board connectors, as they minimize physical bulk while enhancing connectivity quality. As designers

prioritize these aspects, the trend toward choosing board to board configurations for high-density applications

becomes increasingly clear. This shift highlights the need for connectors that not only meet technical specifications

but also align with market demands for compact and efficient design solutions.

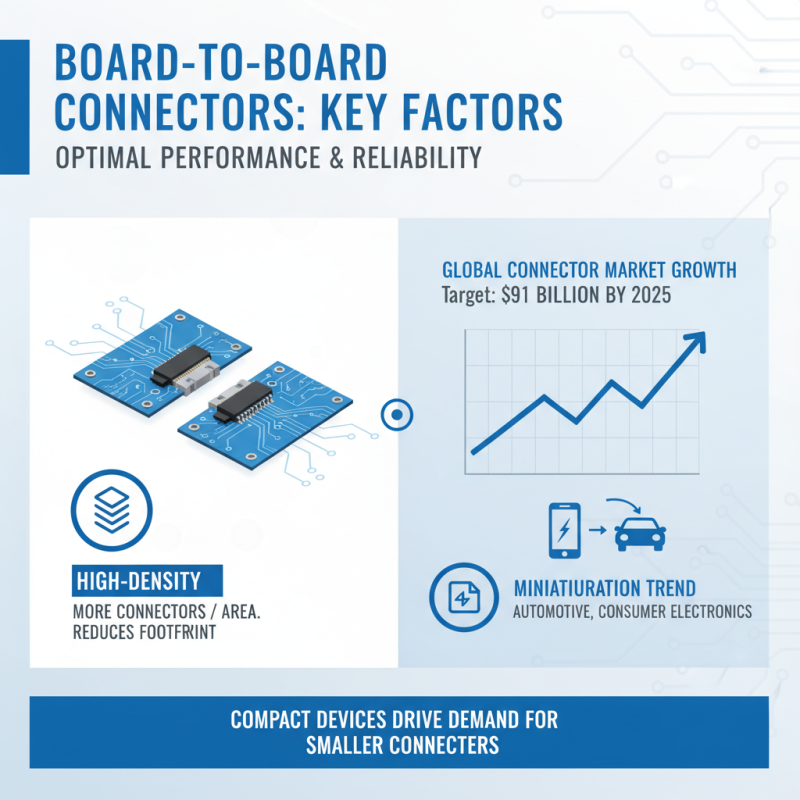

When selecting board-to-board connectors for your next project, several critical factors must be considered to ensure optimal performance and reliability. One of the primary aspects is the connector density, which refers to how many connectors can fit within a certain area on the PCB. According to industry studies, devices are becoming more compact, leading to a surge in demand for high-density connectors. This shift can allow for more efficient use of space, reducing the overall footprint of electronic assemblies. The projected growth of the global connector market, expected to reach approximately $91 billion by 2025, underscores this trend towards miniaturization in various sectors, including automotive and consumer electronics.

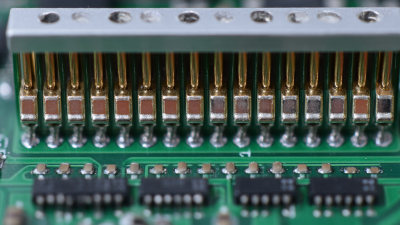

Another vital factor to contemplate is the environmental and mechanical requirements of the application. Connectors must be able to withstand vibrations, temperature variations, and even exposure to moisture, depending on their end use. A report from Research and Markets highlights that nearly 30% of connector failures are attributed to environmental factors, making it imperative to choose connectors that match the specific conditions they'll face. For instance, connectors with gold plating may offer better corrosion resistance and improved conductivity. Additionally, understanding the current and voltage specifications of your application is crucial; ensure that your choice of connector supports the necessary electrical requirements without compromising safety or performance.

The evolution of board-to-board (B2B) connectors is poised to redefine the landscape of electronic interconnections in the coming years. According to a report from MarketsandMarkets, the global board-to-board connector market is expected to grow from USD 6.02 billion in 2020 to USD 9.02 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.3%. This growth is primarily driven by the increasing demand for miniaturization in electronic devices, particularly in sectors such as consumer electronics, automotive, and telecommunications. As devices become more compact yet feature-rich, the need for efficient and reliable B2B connectors becomes crucial.

Future trends indicate a shift towards higher-density connectors capable of supporting increased data rates and improved performance. Innovations in materials and design are enabling manufacturers to produce connectors that not only occupy less space but also enhance thermal management and signal integrity. For instance, the adoption of advanced materials such as polymers and ceramics is leading to connectors that can withstand higher operating temperatures and environmental stresses. Furthermore, the integration of smart features into B2B connectors, such as automated locking mechanisms and embedded sensors, is expected to enhance usability and safety, addressing critical concerns in various applications. As these trends develop, users can anticipate a new wave of connectors that will meet the demanding requirements of the next generation of electronic devices.