In the realm of electronics, the selection of components plays a pivotal role in the success of any project, and male header pins are no exception. These small yet indispensable connectors serve as the backbone for establishing reliable connections within electronic circuits. According to Dr. Alex Thompson, a leading expert in electronic component design, "Choosing the right male header pins can significantly impact the performance and durability of your projects." This underscores the critical nature of understanding the various types, specifications, and applications of male header pins.

As hobbyists and professionals alike embark on their electronic projects, the choice of male header pins can dictate not only the ease of assembly but also the longevity of the connections created. These connectors are available in various configurations, materials, and pin counts, each suited for specific applications ranging from prototyping to finalized electronics. A well-informed decision in selecting male header pins ensures that the end product not only meets performance expectations but also complies with best practices in durability and reliability. In this guide, we will explore how to make the best choice of male header pins to enhance your electronic projects effectively.

Male header pins are essential components in many electronic projects, serving as connectors between different circuit elements. Understanding the types and specifications of these pins is crucial for engineers, hobbyists, and makers alike. Male header pins typically come in various sizes and configurations, including single-row and double-row arrangements. The configuration determines the number of pins available for connecting components, with single-row headers often preferred for simplicity and space-saving designs, while double-row headers offer more connections in a compact footprint.

When selecting male header pins, specifications such as pin diameter, pitch, and mounting type are important factors to consider. The standard pin diameter is usually around 0.025 inches, but variations are available for specific applications. Pitch, which refers to the distance between the centers of two adjacent pins, often ranges from 2.54mm (0.1 inches) to 1.27mm (0.05 inches). Additionally, the mounting type, whether through-hole or surface mount, will influence the ease of assembly and compatibility with your PCB design. Understanding these specifics helps ensure that the selected header pins will meet the requirements of your project, providing reliable connectivity and performance.

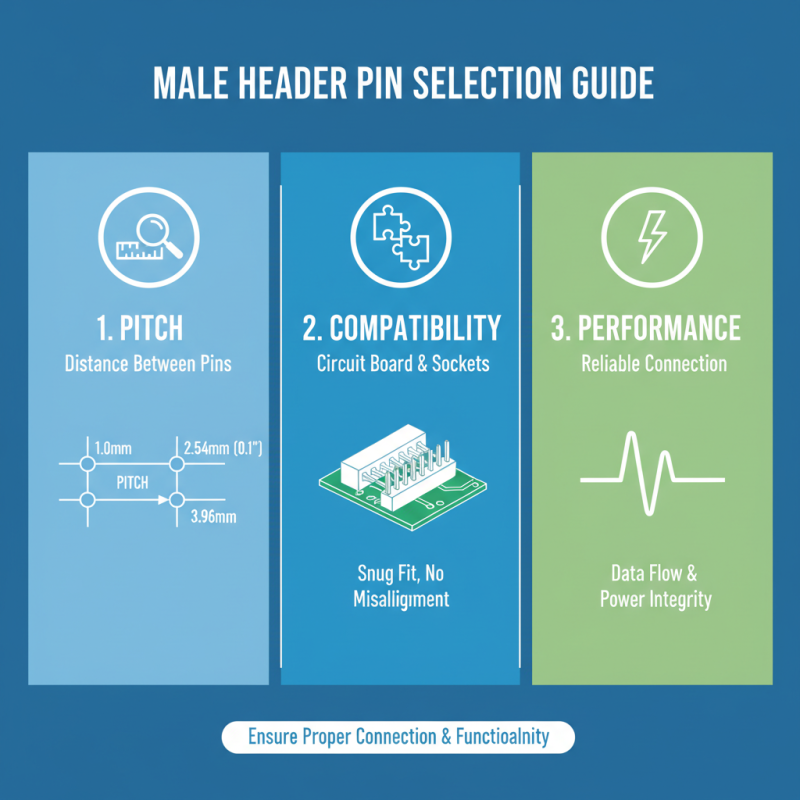

When selecting male header pins for your electronic projects, several key factors should be considered to ensure compatibility and performance. The first aspect to evaluate is the pitch, which refers to the distance between the pins. Common pitches include 1.0mm, 2.54mm, and 3.96mm. Choosing the correct pitch is essential for proper connection with your circuit board and ensuring that the pins can fit snugly into the corresponding sockets without causing misalignment or connection issues.

Another important factor is the pin count, which determines how many connections your project will require. Ensure that your selected male header has enough pins for your needs, while also considering future expandability. Additionally, the material and plating of the pins play a crucial role in their durability and conductivity. Look for headers made from high-quality materials that offer reliable electrical performance and resistance to corrosion, as this will enhance the longevity of your connections and minimize signal degradation in your projects.

When selecting male header pins for your electronic projects, understanding compatibility and application areas is crucial. Male header pins are frequently used in prototyping and circuit connections due to their straightforward design and ease of use. They come in various sizes, pin counts, and configurations, which means that ensuring compatibility with your motherboard, microcontroller, or other components is essential. For example, while some headers may fit perfectly into standard 0.1-inch pitch sockets, others may be designed for different pitches, which can lead to connection issues.

Additionally, the application areas for male header pins vary greatly. For hobbyists, they are commonly used in DIY electronics projects, allowing for easy connections between microcontrollers and other peripherals such as sensors or displays. In industrial applications, they are often employed in circuit boards for secure connections that withstand vibration and environmental stresses. When considering your project’s requirements, think about factors such as the number of pins needed, the environment in which the project will operate, and whether the pins need to be removable or permanently soldered. Understanding these elements will help you choose the best male header pins tailored to your specific needs.

| Pin Count | Pin Spacing (mm) | Material | Max Current Rating (A) | Temperature Range (°C) | Applications |

|---|---|---|---|---|---|

| 2 | 2.54 | Gold-Plated Brass | 1 | -55 to 125 | Simple circuits, Prototyping |

| 4 | 2.54 | Nickel-Plated Steel | 2 | -40 to 85 | Sensor connections, Boards |

| 8 | 2.00 | Oxygen-Free Copper | 1.5 | -20 to 70 | Microcontroller interfaces, Robotics |

| 16 | 1.00 | Gold-Plated Brass | 3 | -55 to 125 | High-density circuits, PCBs |

| 20 | 2.54 | Nickel-Plated Steel | 2 | -40 to 125 | Complex devices, Audio equipment |

| 40 | 2.00 | Tinned Copper | 1 | -20 to 80 | Servers, Networking equipment |

When sourcing quality male header pins for your electronic projects, it’s essential to consider several key factors to ensure that you choose components that meet both your project's technical requirements and durability standards. First and foremost, examine the materials used in the construction of the header pins. Opt for metal alloys with good conductivity and corrosion resistance, as these will enhance the reliability and lifespan of your connections. Additionally, check that the coatings applied, such as gold or tin, are suitable for preventing oxidation while providing a strong electrical connection.

Another crucial aspect is the pin spacing and layout. Different projects might require specific configurations, so ensure that the header pins' dimensions align with your circuit board design. Additionally, consider sourcing from reputable suppliers who provide detailed specifications and testing certifications for their products. This will not only help in maintaining quality but also provide assurance of performance, especially in projects where reliability is paramount. Ultimately, taking the time to carefully select your male header pins can greatly influence the functionality and longevity of your electronic assemblies.

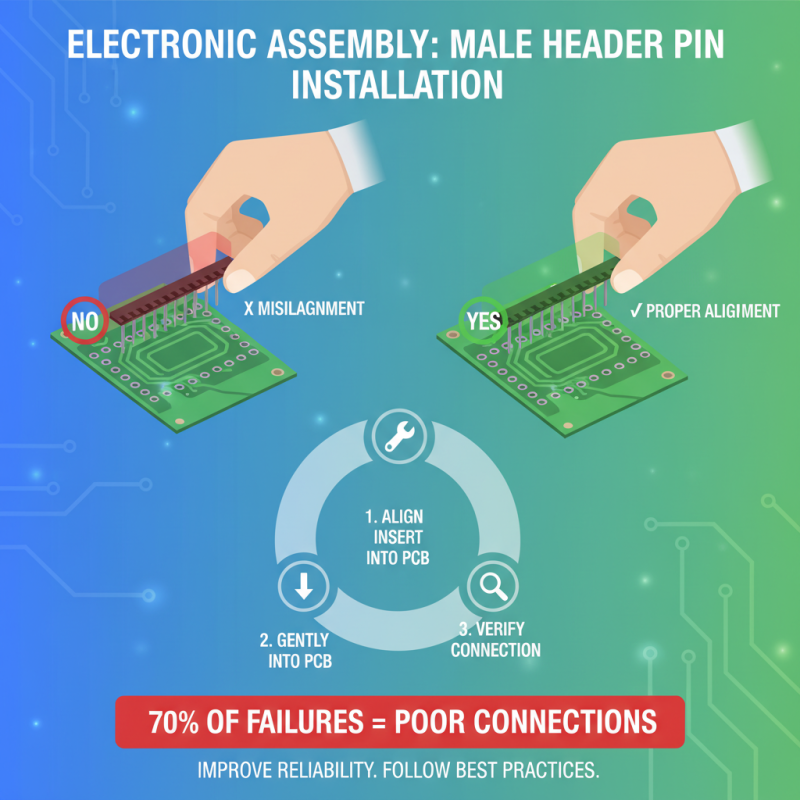

When working on electronic projects, the installation of male header pins is crucial to ensuring proper connectivity and functionality. According to a recent industry report, approximately 70% of failures in electronic assemblies can be attributed to poor connections. Therefore, adhering to best practices during installation can significantly reduce these errors. It is essential to start by ensuring that the pins are aligned correctly with the corresponding female connectors before inserting them into the PCB. A misaligned insertion can lead to bent pins or incomplete connections, which may compromise the integrity of the circuit.

Another vital aspect of using male header pins effectively is to consider the temperature and soldering techniques applied during installation. High-quality soldering, utilizing a temperature range between 350°C to 400°C, ensures a solid connection that minimizes potential heat damage. Research has indicated that maintaining this temperature helps in achieving a reliable solder joint, reducing the risk of joint failure over time. Additionally, utilizing clean soldering techniques and properly fluxing the pins before soldering can enhance the connection quality and longevity, ultimately contributing to better performance in your electronic projects. Following these installation best practices will ensure efficient functionality and durability in your designs.