Selecting the perfect Male Header Pins for your electronic projects is crucial for ensuring reliable connections and optimal performance. With a plethora of options on the market, the task can seem daunting, especially for those new to electronics or even seasoned engineers looking to refine their components. This ultimate guide aims to simplify the selection process by providing a comprehensive checklist that covers the essential factors to consider. From pin configuration and size to material quality and compatibility, understanding these elements will empower you to make informed choices that enhance your circuit designs.

Whether you’re working on a DIY project, prototyping a new invention, or assembling a larger system, having the right Male Header Pins is foundational to achieving a successful outcome. Join us as we delve into the key considerations that will lead you to the ideal pins for your needs.

Whether you’re working on a DIY project, prototyping a new invention, or assembling a larger system, having the right Male Header Pins is foundational to achieving a successful outcome. Join us as we delve into the key considerations that will lead you to the ideal pins for your needs.

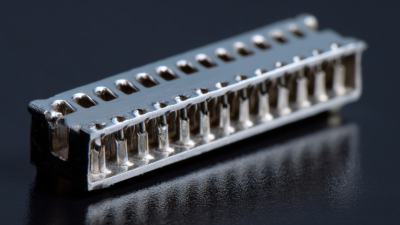

When selecting male header pins for electronic applications, it is essential to assess key features to ensure optimal performance and compatibility. One crucial aspect is the pin pitch, which is the distance between pins. Standard pitches are typically 2.54mm and 1.27mm. According to industry reports, using the appropriate pin pitch can enhance connectivity reliability, especially in compact electronic devices. Selecting a pitch that fits your PCB design will prevent solder bridging and maintain signal integrity.

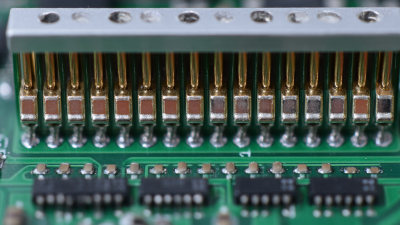

Another significant factor is the material and plating of the header pins. Common materials include brass and phosphor bronze, with gold, tin, or nickel plating providing different levels of corrosion resistance and conductivity. A 2021 study from the Electronic Components Industry Association indicates that connectors with gold plating can improve electrical performance by up to 10% in high-frequency applications. Thus, it's vital to match the plating with the intended application environment.

**Tips for Selecting Male Header Pins**:

- Always consider the current and voltage ratings of your application to ensure the selected pins can handle the required electrical load.

- Look for header pins with a locking mechanism for added security in connectors to prevent accidental disconnection.

- Evaluate the operating temperature range specified by manufacturers to guarantee that the pins perform optimally under varying conditions.

When selecting the perfect male header pins, understanding the

pin configuration is crucial for ensuring seamless connectivity in your electronic projects.

Pin configuration determines how devices communicate, impacting everything from signal integrity to mechanical stability.

A thorough grasp of the male header pin specifications—including the number of pins, pitch, and orientation—can significantly influence the success of your design.

Tip: Always consider the specific requirements of your project when choosing pin configurations.

For instance, devices requiring tight spacing may benefit from a finer pitch, while larger connectors may be ideal for high-power applications.

Additionally, evaluate whether a straight or right-angle header suits your layout best, as this can affect how your components connect within the overall assembly.

Tip: Testing different configurations in a breadboard setup can be invaluable.

Not only does it help visualize the connections, but it also allows for identification of potential issues before finalizing your design.

By experimenting with various pin placements and header styles, you can optimize your circuit while ensuring that the connectors fit seamlessly into your evolving project.

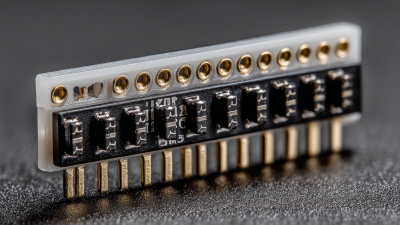

When selecting the perfect male header pins for your electronic projects, evaluating material types is crucial. The most common materials used for male header pins are gold, tin, and nickel. Gold-plated pins offer excellent conductivity and resistance to corrosion, making them ideal for high-performance applications. However, the cost may be a factor to consider. Tin-plated pins, on the other hand, provide a good balance between conductivity and affordability, although they may not perform as reliably over time due to potential oxidation.

Durability is another essential factor when choosing male header pins. The physical properties of the materials determine how well the pins withstand mechanical stress and environmental conditions. Nickel-plated pins are known for their strength and resistance to wear, making them suitable for applications where frequent connections and disconnections occur. Ultimately, the choice of material will significantly impact both the reliability and functionality of the connections in your electronics, so it’s essential to weigh these factors carefully against the specific requirements of your project.

When selecting male header pins, understanding industry standards and certifications is crucial for ensuring quality and reliability. Male header pins are essential components in electronic connections, often used in circuit boards and various electronic devices.

According to a report by the International Electrotechnical Commission (IEC), adhering to the IPC-A-610 standards can significantly reduce the failure rates of electronic assemblies, highlighting the importance of compliance when choosing header pins. This standard ensures a uniform quality level across different manufacturers, which is vital for longevity and performance.

Additionally, certifications such as ISO 9001 indicate that a manufacturer has met international quality management standards. A survey conducted by the Quality Assurance Agency found that products from ISO-certified companies have a 30% lower defect rate than those from non-certified manufacturers.

When selecting male header pins, ensuring that they are sourced from suppliers who hold recognized certifications can be a decisive factor in the reliability of electronic devices. This attention to quality standards not only assures long-term performance but also enhances the overall safety of the finished products.

When selecting male header pins, it's crucial to analyze the cost versus performance to ensure that your choice meets both budgetary constraints and technical requirements. According to a recent industry report, manufacturers have seen a 15% increase in the demand for high-performance pins that can withstand higher temperatures and provide reliable connections. Investing in quality header pins is paramount; while cheaper options may save money upfront, they often lead to increased failure rates and higher costs in the long run due to the need for replacements or repairs.

Furthermore, the performance metrics for male header pins can vary significantly based on their material and design. For instance, pins made from gold-plated brass offer superior conductivity, which is essential for applications in high-frequency environments. A survey conducted among engineers revealed that over 60% prioritize material quality over initial costs when selecting components for their projects. This decision ultimately enhances overall system performance and durability, illustrating that being informed about cost versus performance is an integral part of the purchasing process in the electronics industry.