In today's fast-paced electronic industry, optimizing component selection is crucial for enhancing the performance and reliability of devices. Among the myriad of options available, Socket Pin Headers have emerged as a vital component in ensuring seamless connectivity in various applications, from consumer electronics to automotive systems. According to a recent industry report by MarketsandMarkets, the connector market is projected to reach $85.3 billion by 2026, driven by the growing demand for high-speed data transmission and miniaturization of electronic devices. This underscores the importance of selecting the right Socket Pin Header types for specific applications, where understanding their unique features and capabilities can lead to improved efficiency and reliability. In this blog, we will delve into the different types of Socket Pin Headers, their appropriate use cases, and a comprehensive guide on selecting the best options for global buyers looking to enhance their electronic designs.

As we look toward 2025, the landscape of socket pin header technology is set to evolve significantly, fueled by several emerging trends. With the ongoing innovation in connector designs, such as the introduction of co-packaged optics and advancements in automotive connectors, the demand for efficient and reliable socket pin headers is rising. These innovations not only promise enhanced performance but also address the growing complexity of modern electronic systems, particularly in high-speed data applications.

Additionally, the projected surge in markets like clad metals for battery connectors and PCB connectors underscores the necessity for adaptable and future-proof socket pin headers. The growth trajectory, especially within the Asia Pacific region, highlights a robust demand for versatile connector solutions as industries navigate the challenges of advanced manufacturing processes. As manufacturers prepare to leverage new technologies, socket pin headers will play a pivotal role in ensuring seamless integration and superior connectivity across various applications, ranging from consumer electronics to automotive systems.

When selecting socket pin headers, reliability and efficiency are paramount for global buyers. One of the critical features to consider is contact resistance. Studies indicate that a lower contact resistance can significantly enhance the overall performance of electronic devices. For instance, according to a 2022 industry report by Research and Markets, connectors with contact resistance lower than 10 mΩ can improve energy efficiency by up to 5% in various applications, which can lead to substantial cost savings over time.

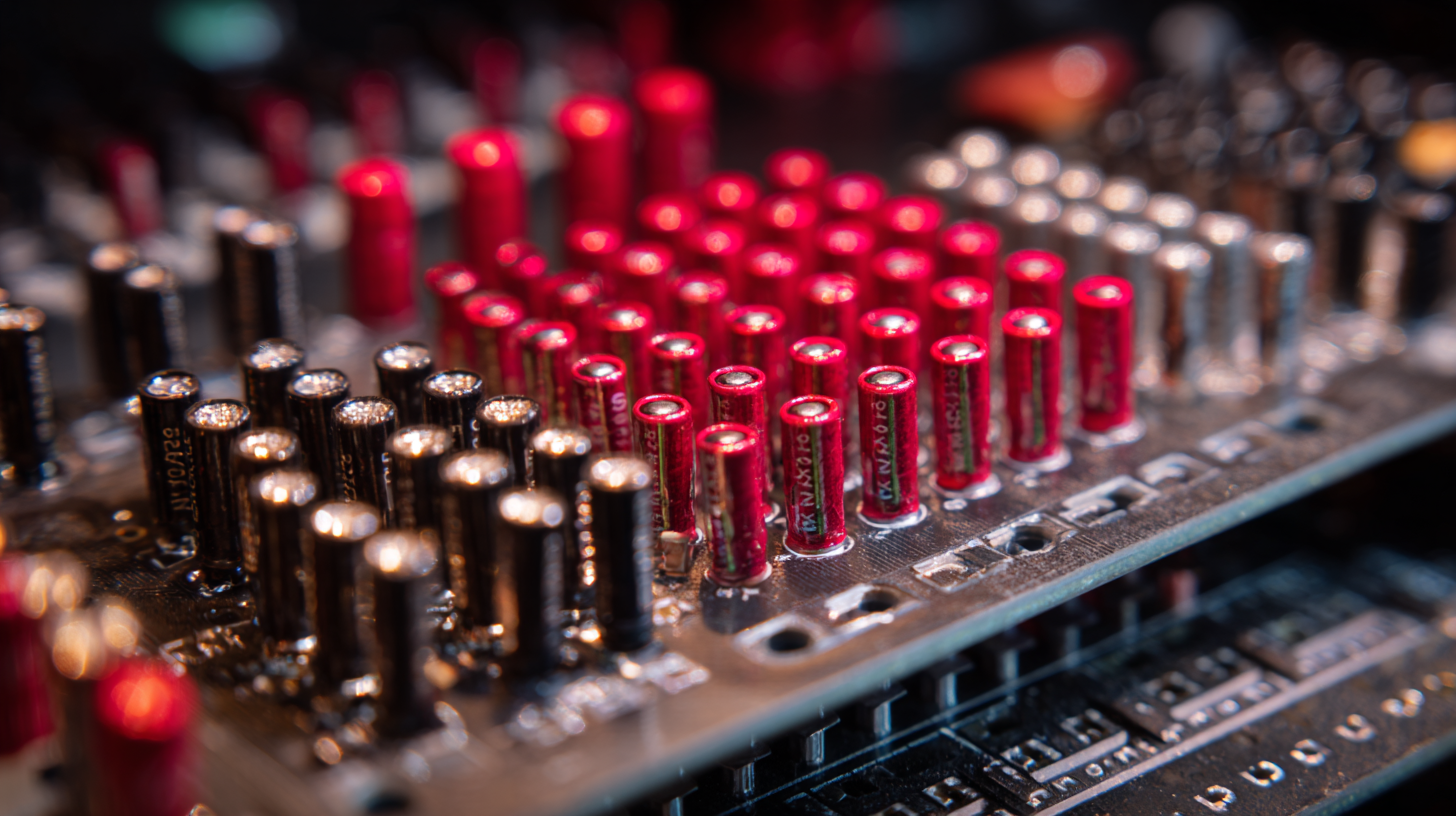

Another essential feature is the material used in the construction of socket pin headers. High-quality materials such as phosphor bronze or copper alloy provide better conductivity and longevity. A report by the International Electrotechnical Commission (IEC) notes that using premium materials can enhance the lifespan of socket pin headers by up to 50%, ensuring more extended reliability in demanding environments. Additionally, compatibility with various mounting options, including surface mount technology (SMT) and through-hole techniques, increases their versatility and usability across different electronic applications.

This chart illustrates the key features to look for in reliable socket pin headers, highlighting important performance metrics such as durability, temperature tolerance, and ease of use.

In the competitive landscape of electronic components, socket pin headers play a crucial role in ensuring efficiency and reliability for a wide array of applications. A recent market analysis by Industry Research reveals that the global socket pin header market is projected to grow at a CAGR of 6.2% from 2021 to 2026, reflecting increasing demand in sectors such as automotive and consumer electronics. This growth underlines the importance of selecting the right manufacturers, as the quality of socket pin headers can significantly impact both performance and production costs.

When examining the leading manufacturers in this field, companies such as Molex, TE Connectivity, and Hirose Electric emerge as frontrunners due to their commitment to innovation and quality assurance. According to a report by MarketsandMarkets, these companies dominate the market, collectively holding over 40% of the global share. Their advancements in design and production techniques have resulted in socket pin headers that not only meet stringent industry standards but also cater to evolving customer needs. Furthermore, their global supply chains enable them to provide reliable components to buyers worldwide, reinforcing the notion that investing in high-quality socket pin headers can lead to significant operational efficiencies and enhanced product performance.

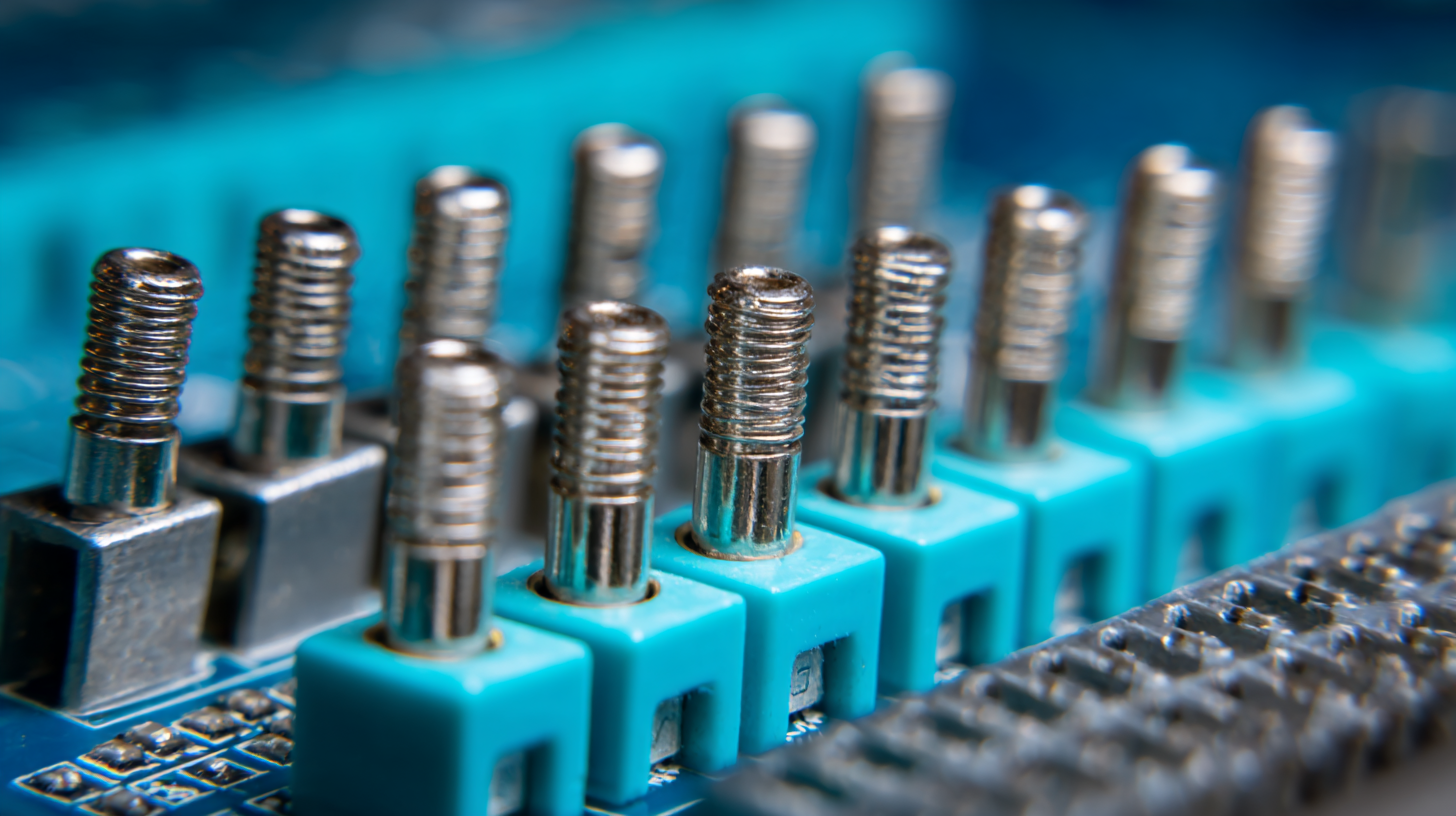

When selecting the ideal socket pin headers, there are several critical factors to consider to ensure efficiency and reliability in your projects. First, evaluate the pitch and row configuration of the header. The pitch, which refers to the distance between the pins, should align with your PCB design requirements. Similarly, understanding whether you need single-row or double-row headers can significantly impact the layout and spacing of your components.

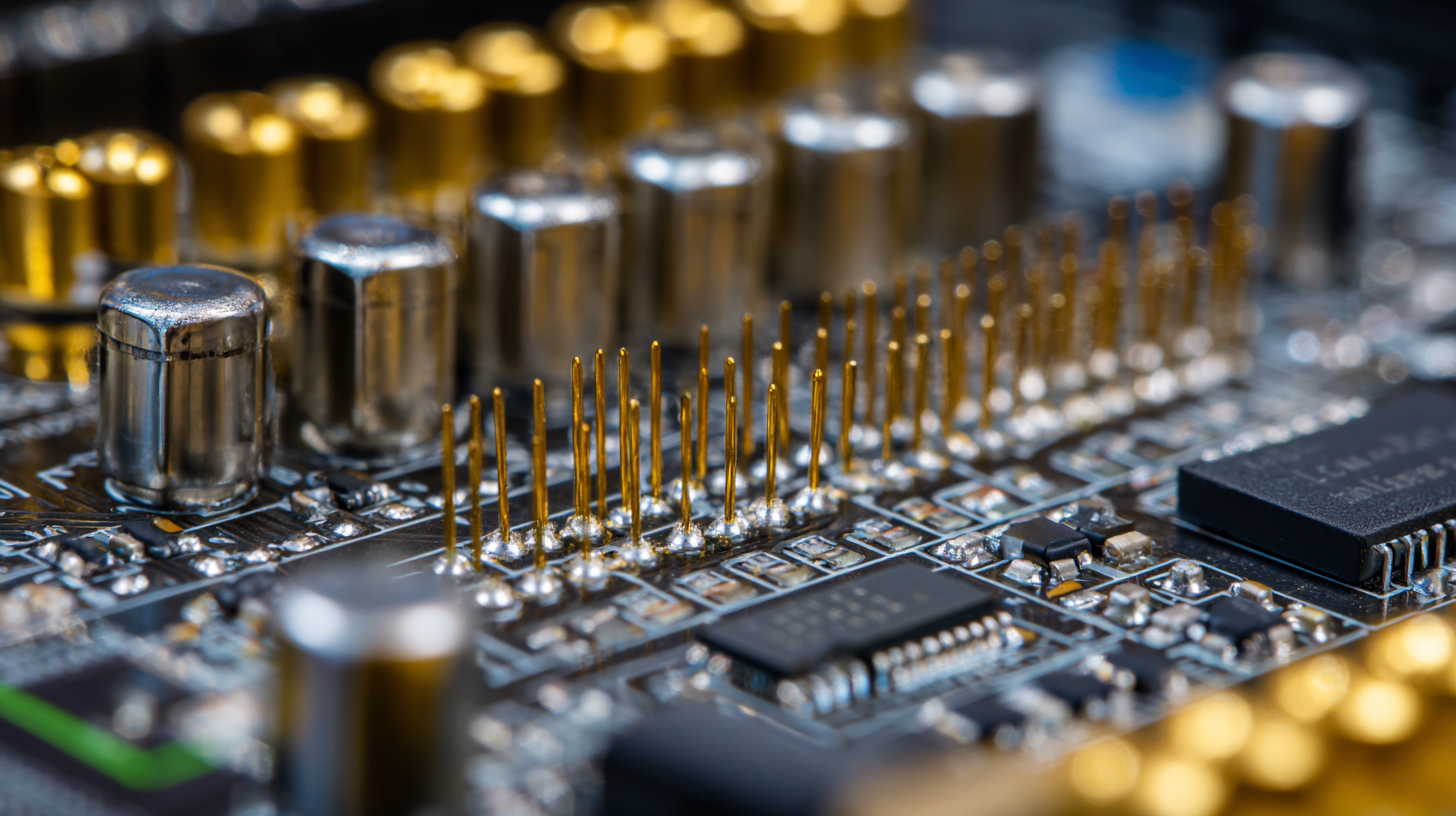

Next, don’t overlook the material and plating options. Headers are commonly made from a variety of materials including brass and steel, but the choice will affect conductivity and corrosion resistance. Gold plating is often favored for its superior conductivity and durability, making it a popular choice for high-frequency applications. Additionally, ensure that the rated current and voltage of the headers align with your project specifications to prevent unnecessary failures.

Lastly, consider the manufacturer’s reputation and product certifications. Opting for well-known brands with reliable quality assurance processes can provide peace of mind, ensuring that the headers you choose will perform as expected under various conditions. By paying close attention to these key aspects, you can confidently select socket pin headers that meet your needs and enhance the overall reliability of your electronic devices.

| Parameter | Description | Value |

|---|---|---|

| Pin Count | Number of pins on the header | 2-40 |

| Pin Pitch | Distance between the centers of adjacent pins | 2.54 mm/0.1 inch |

| Current Rating | Maximum current each pin can handle | 1 A |

| Rated Voltage | Maximum voltage applicable across the header | 250 V AC |

| Operating Temperature | Temperature range for reliable operation | -40°C to +105°C |

| Material | Material used for pins and housing | Phosphor bronze with gold plating |

| Mounting Type | Type of mounting for the header | Through-hole / SMD |

In today's fast-paced electronics industry, sourcing high-quality socket pin headers is crucial for optimizing reliability and enhancing overall efficiency. According to a recent report by MarketsandMarkets, the global socket pin header market is expected to reach USD 1.8 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth is driven by the increasing demand for efficient connectivity solutions across a variety of sectors, including consumer electronics, automotive, and industrial automation.

When looking to optimize your socket pin header purchases, it is essential to narrow your focus. **Tip 1**: Always prioritize suppliers who adhere to industry standards, such as RoHS and REACH compliance, ensuring that the components meet environmental safety standards. **Tip 2**: Leverage global sourcing platforms to compare and evaluate multiple suppliers swiftly, which can significantly reduce lead time and costs. Finally, **Tip 3**: Consider long-term partnerships with manufacturers who offer comprehensive warranties and support services, as their expertise can add substantial value to your procurement process.

As the demand for reliable electronic components continues to grow, leveraging strategic sourcing tips can streamline the purchasing process and ultimately enhance the performance of the final products.