In the evolving landscape of industrial operations, selecting the best industrial connectors is crucial for project success. According to a recent report by MarketsandMarkets, the industrial connector market is projected to reach $9.3 billion by 2026, reflecting a growing demand for reliable connectivity solutions. Adopting the right industrial connector can significantly enhance equipment efficiency and reduce downtime.

Expert John Smith, a renowned authority in the field, emphasizes the importance of choosing quality connectors. He stated, "The right industrial connector can make or break a project's success." As industries embrace automation and IoT, the need for robust connectors has never been more pressing. However, distinct challenges arise, including compatibility and durability across various environments.

Selecting the best industrial connectors requires careful consideration. Factors like temperature ranges, material resilience, and interface type must be factored in. All these details can impact performance significantly. An informed choice not only improves functionality but also extends product life, leading to long-term savings. This topic warrants deeper exploration to achieve optimal outcomes.

Industrial connectors are critical components in various projects. They ensure reliable communication and power transmission between devices. Without them, systems may face failures or inefficiencies. Choosing the right connector can significantly affect project outcomes.

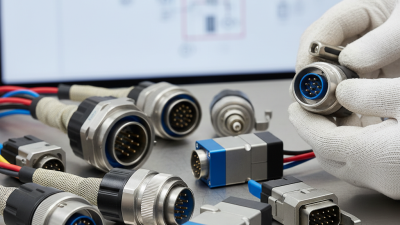

These connectors come in various types, including circular, rectangular, and modular designs. Each type serves a specific purpose. For instance, circular connectors are often used in rugged environments. However, not all projects consider the environmental factors, leading to potential issues.

When selecting connectors, keep compatibility in mind. Many industries have specific requirements. Ensure the connectors match the specifications required for durability. Ignoring these details can provoke unexpected complications. Reflecting on past experiences can help in making informed choices. Consider testing connectors in real conditions to observe their performance over time.

Industrial connectors play a vital role in various projects. They ensure reliable connections in harsh environments. Understanding different types can guide your choices effectively. Key categories include circular connectors, rectangular connectors, and modular connectors. Each type serves specific needs and conditions.

Circular connectors are common in machinery and automotive applications. They provide durability and resistance to vibration. Rectangular connectors often accommodate larger data and power requirements. This makes them suitable for industrial automation. Modular connectors offer flexibility by allowing custom configurations. This adaptability can solve unique project challenges.

Selecting the right connector can be daunting. Factors like environmental conditions and usage must be considered. Sometimes, connectors may not meet expectations. Issues like corrosion and wear can arise. Reflecting on past experiences can improve future selections. Evaluating options thoroughly can lead to better results.

When selecting industrial connectors, several key factors come into play. Environmental conditions are critical. Connectors must withstand dirt, moisture, and extreme temperatures. According to a report by the Industrial Connector Association, over 30% of connector failures are linked to environmental exposure. Harsh environments can severely impact performance and durability.

Another important factor is the application-specific requirements. Connectors need to support the electrical specifications of the project. For instance, high-frequency applications may require specialized connectors to reduce signal loss. Research suggests that up to 25% of industrial machinery failures are caused by inadequate connectivity. Choosing connectors with the right specifications can enhance performance and reliability.

Connector types also vary significantly. From circular connectors to rectangular types, each has its own advantages. Circular connectors are often preferred for their compact design and ease of use. Yet, they may limit spacing in tight areas. Understanding the trade-offs between different types is essential for project success, as insufficient analysis can lead to costly redesigns later.

| Connector Type | Application | Environment Rating | Current Rating (A) | Voltage Rating (V) |

|---|---|---|---|---|

| Circular Connectors | Robotics, Automation | IP67 | 20 | 250 |

| DIN Connectors | Industrial Machinery | IP65 | 16 | 400 |

| RJ45 Connectors | Network Communication | IP20 | 1 | 100 |

| M12 Connectors | Sensor Integration | IP67 | 4 | 60 |

| Heavy-Duty Connectors | Power Distribution | IP66 | 125 | 1000 |

When selecting industrial connectors, industry standards and ratings are crucial. These connectors must withstand harsh environments and heavy usage. The International Electrotechnical Commission (IEC) provides standards like IEC 60529, which rates the ingress protection of connectors. This rating shows how well a connector resists dust and water. Connectors with IP67 ratings can endure submersion in water up to 1 meter for 30 minutes, making them ideal for outdoor and industrial applications.

In addition to standard ratings, performance under electrical load is important. For instance, connectors rated for 16A can handle rigorous electrical demands. However, mismanagement in load ratings can lead to failures. According to a recent report, 15% of industrial equipment downtime is due to connector failures. Ensuring that connectors are not overloaded is crucial for uninterrupted operation.

Choosing reliable connectors involves looking at these standards. Sometimes, connectors that meet the minimum requirements fall short in real-world applications. Engineers must evaluate both the specifications and the actual performance data. In the end, connectors should be chosen carefully to balance reliability and project demands.

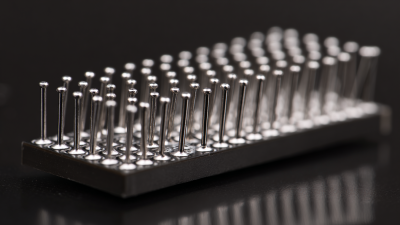

The field of industrial connectors is evolving quickly. New technologies are offering innovative solutions. These advancements enhance the way machines communicate. One notable trend is the rise of smart connectors. These devices can monitor systems in real-time. They provide crucial data for maintenance and efficiency.

Wireless technology is also gaining traction. It eliminates the need for cumbersome wiring. However, this trend raises concerns about reliability. Not all industrial environments are suitable for wireless communication. Another interesting development is miniaturization. Smaller connectors can accommodate tight spaces in machinery. But, this can complicate maintenance tasks.

Additionally, sustainability is becoming a priority. Manufacturers are focusing on eco-friendly materials. This shift can reduce the environmental impact. Yet, the challenge remains in balancing performance and sustainability. Not every solution is perfect. The industry must continuously adapt to shifting demands.