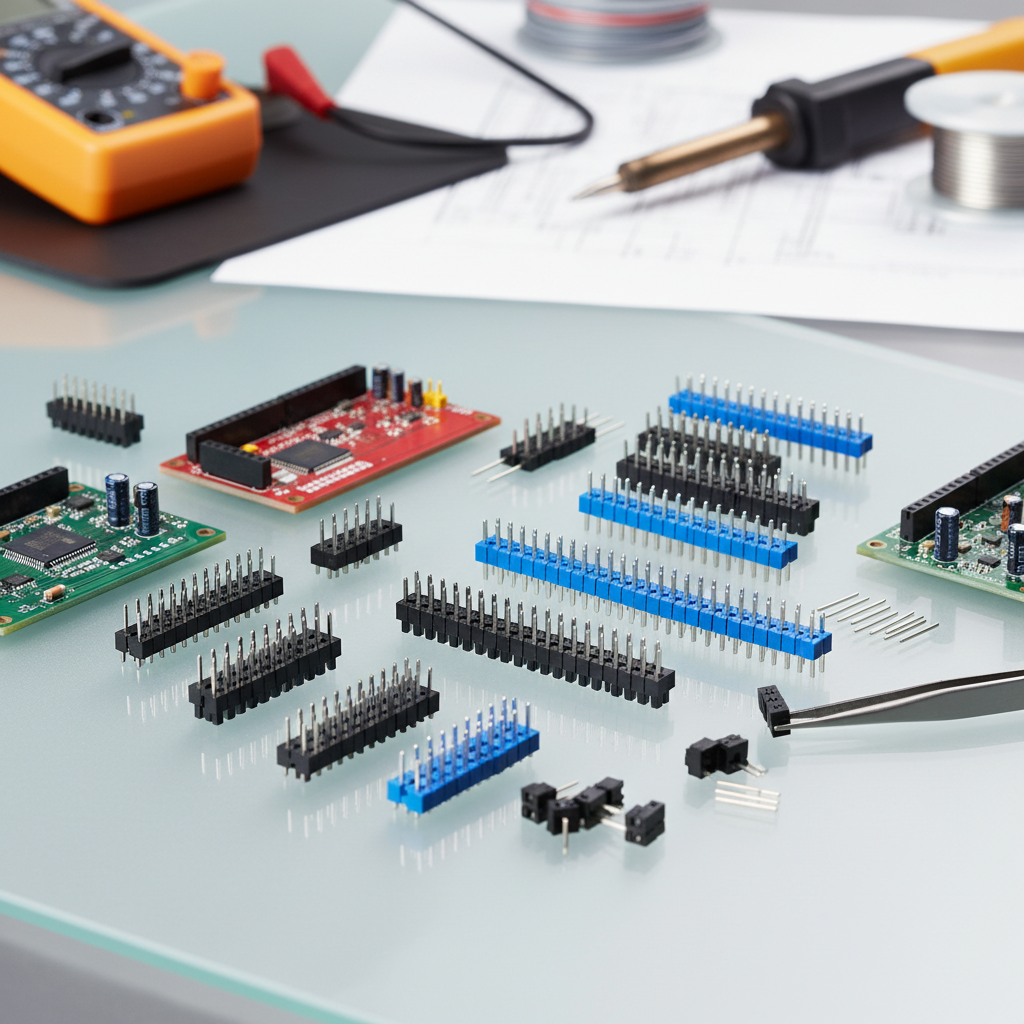

In the realm of electronics, the significance of a reliable and efficient connection cannot be overstated. One component that stands out due to its versatility and effectiveness is the Pin Header Socket. According to Dr. Emily Carter, a renowned expert in electronic components, “The Pin Header Socket is the backbone of modular connections, facilitating easy assembly and disassembly in various electronic projects.” The adoption of Pin Header Sockets in DIY electronics, prototyping, and mass production has revolutionized the way engineers and hobbyists approach connectivity.

As we delve into the top 10 benefits of utilizing Pin Header Sockets, it's essential to recognize their impact on enhancing both the functionality and reliability of electronic designs. From their ease of use and adaptability in various applications to their cost-effectiveness and simplicity in troubleshooting, these sockets serve as a crucial link in any electronic project. As technology continues to advance and the demand for sophisticated electronic solutions grows, understanding the advantages of Pin Header Sockets becomes increasingly important for both seasoned professionals and newcomers to the field.

Pin header sockets offer numerous advantages in electronic projects, primarily through their ability to create reliable connections. These components ensure a stable interface between various electronic devices, which is crucial for the performance and longevity of any project. When using pin headers, the precision of connection points significantly reduces the risk of loose contacts that can lead to erratic behavior or complete device failure. This reliability is essential, especially in applications where consistent performance is mandatory, such as in automotive or aerospace electronics.

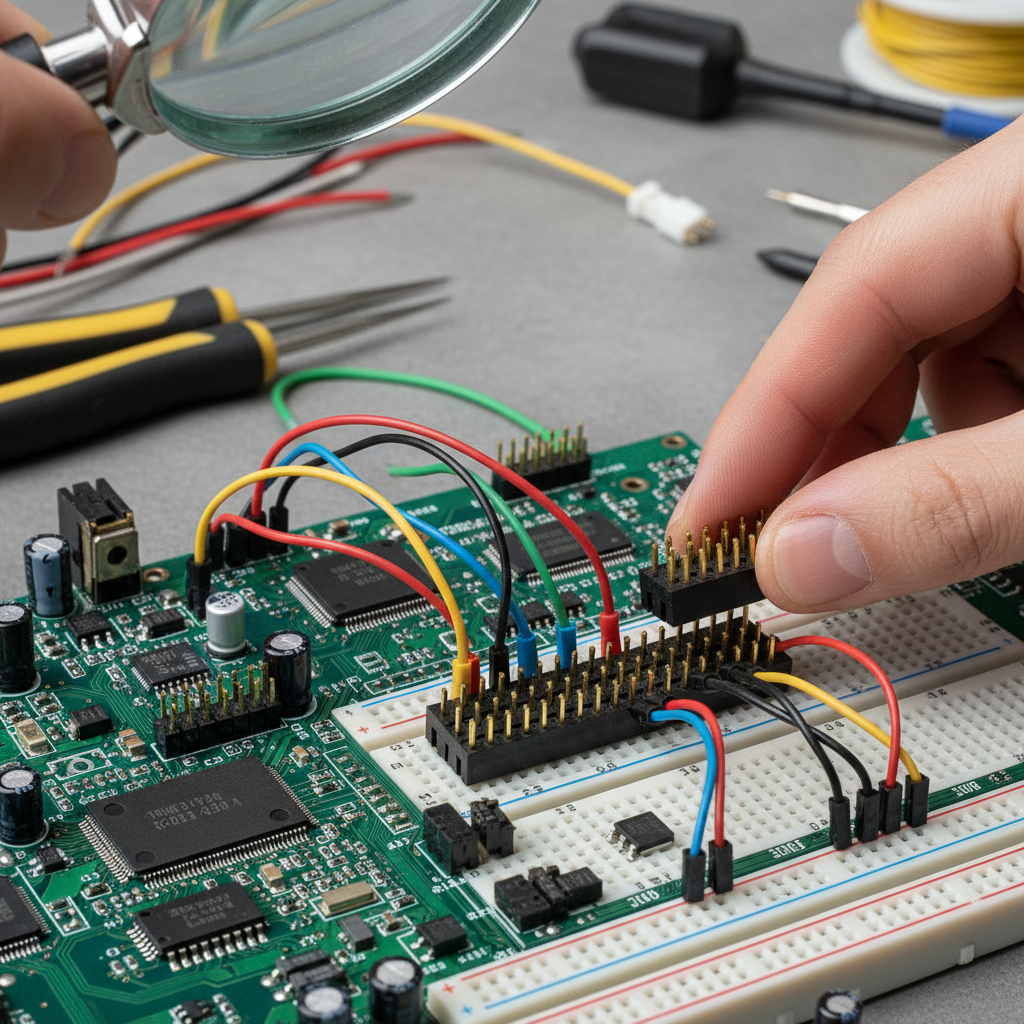

Moreover, pin header sockets facilitate easy prototyping and testing. Their design allows for simple insertion and removal, enabling engineers to quickly swap components without soldering, streamlining the development process. This modularity not only enhances efficiency but also supports iterative designs by allowing rapid adjustments. The ability to create a reusable and adaptable electronic platform makes pin header sockets an ideal choice for hobbyists and professionals alike, emphasizing their role in fostering innovation in electronics.

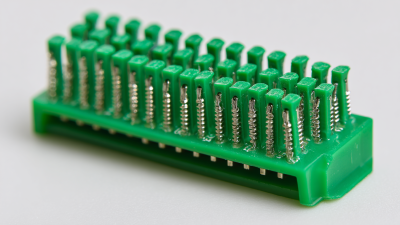

Pin header sockets are an essential component in a wide array of electronic projects due to their unparalleled versatility. They serve as a reliable interface for connecting various electronic components, such as microcontrollers, sensors, and displays. This adaptability makes pin header sockets a preferred choice for hobbyists and professionals alike, enabling seamless integration of different modules within a single project.

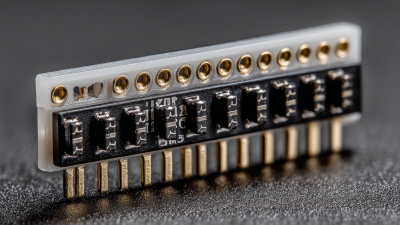

When incorporating pin header sockets, one crucial tip is to select the appropriate pin spacing and layout based on your project’s specifications. Standard 2.54mm spacing is common, but ensure it aligns with your components to prevent issues during assembly. Additionally, ensure to use a proper soldering technique to secure the sockets firmly; this enhances durability and ensures a solid electrical connection.

Another useful insight is to consider the use of female header sockets when dealing with frequent component changes or testing. This allows for easy connectivity and disconnection, saving time and effort during the development phase. By leveraging the versatility of pin header sockets, you can streamline your workflow, making adjustments as needed without a significant overhaul of your circuitry.

One of the primary benefits of using pin header sockets in electronic projects is their exceptional ease of use, especially in the realms of prototyping and development. According to a report by the Consumer Electronics Association, nearly 70% of electronics developers consider ease of integration as a critical factor when selecting components for their projects. Pin header sockets simplify this process by providing a reliable and straightforward method for establishing electrical connections between various components. This not only streamlines the assembly process but also significantly reduces the likelihood of errors during prototyping, allowing developers to focus on innovation rather than troubleshooting connectivity issues.

Incorporating pin header sockets into electronic designs also enhances flexibility in prototyping. Research from the IEEE indicates that over 50% of engineers value modular designs that allow for easy adjustments and modifications during testing phases. Pin header sockets enable quick and easy swapping of components, which is essential during initial design iterations. This adaptability facilitates rapid development cycles, allowing engineers to prototype, test, and iterate their designs efficiently, ensuring they can meet project deadlines and accommodate last-minute changes.

This bar chart illustrates the top 10 benefits of using pin header sockets in electronic projects. Each benefit is evaluated on a scale of 1 to 10, demonstrating their importance in prototyping and development.

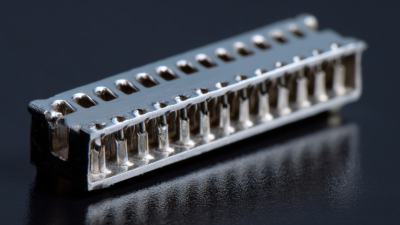

Pin header sockets are a vital component in electronic projects, renowned for their durability and longevity. These connectors offer superior resistance to wear and tear, which is crucial in both prototyping and mass production. According to a report by Research and Markets, the global connector market is projected to reach $66.18 billion by 2026, driven largely by the demand for reliable, long-lasting components. Pin header sockets, often made from high-quality materials such as nylon or thermoplastic, can withstand temperatures ranging from -40°C to +105°C, making them an ideal choice for various applications.

Furthermore, the mechanical strength of pin header sockets ensures that they maintain a secure connection over time. A study published in the Journal of Electronics Materials highlights that connectors that meet the IPC-2221 standards exhibit significantly reduced failure rates when subjected to vibration and thermal cycling tests. This is particularly important in industries such as automotive and aerospace, where component reliability directly impacts safety and performance.

The longevity of pin header sockets not only provides peace of mind but also reduces the need for frequent replacements, ultimately cutting costs in electronic design and manufacturing.

When embarking on DIY electronics projects, cost-effectiveness is a crucial factor for hobbyists and professionals alike. Pin header sockets offer an affordable solution for creating reliable connections between components. Their low production cost, combined with the ability to easily replace faulty connections, can significantly reduce overall project expenses. Furthermore, these sockets can simplify the assembly process, allowing for quicker prototyping and fewer wasted materials, making them an excellent investment for those looking to keep budgets in check.

**Tip:** Always consider bulk purchasing options for pin header sockets. Many suppliers offer discounts on bulk orders, which can lead to substantial savings for ongoing or multiple projects.

In addition to their affordability, pin header sockets provide versatility in design. They can be used with various devices and connectors, making them an excellent choice for diverse electronic applications. By allowing for modular designs, pin header sockets can facilitate the integration of different components without the need for extensive rewiring. This not only saves time and costs but also allows for easy upgrades or repairs in the future.

**Tip:** Take the time to organize your pin header sockets in labeled containers. Keeping them sorted by size and type can help streamline your project workflow and prevent confusion during assembly.