As we look towards 2026, the Industrial Connector market is set to evolve rapidly. According to a recent report from the Industrial Automation Council, global demand for Industrial Connectors is projected to grow by 7% annually over the next few years. This growth reflects an increasing need for reliable connectivity in advanced manufacturing and automation systems.

Dr. Jennifer Smith, a leading expert in the Industrial Connector sector, emphasizes, “The future of Industrial Connectors lies in their ability to support high-speed communication and ruggedness.” Industries are pushing for connectors that not only meet performance standards but also ensure longevity in harsh environments.

However, despite technological advancements, challenges remain. Many manufacturers still grapple with compatibility issues and the need for industry standards. As we move forward, the focus should be on innovation while addressing these shortcomings. The landscape of Industrial Connectors is changing, and staying informed is crucial for stakeholders in this dynamic field.

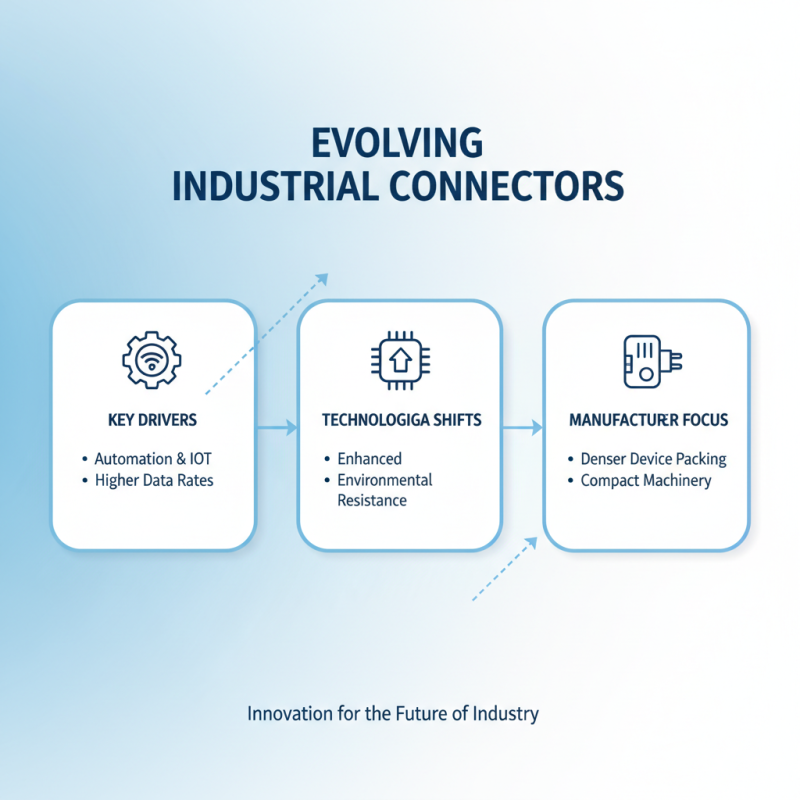

The landscape of industrial connectors is evolving rapidly. Emerging technologies are playing a crucial role in this transformation. Innovations in automation and IoT are pushing for connectors that can handle higher data rates and more robust environmental resistance. Manufacturers are increasingly focusing on miniaturization. Smaller connectors allow for denser packing in devices, which is essential in today's compact machinery.

Wireless technology is also making waves. Systems that rely solely on wireless connections require innovative connector solutions for backup and power supply. The trend toward more flexible connectors is evident, allowing for quick deployment and reconfiguration. However, this shift raises challenges in maintaining reliability and performance. Not all designs meet the rigorous testing standards required in industrial settings.

Sustainability is becoming a vital concern. The push for eco-friendly materials is growing. However, balancing performance with sustainability can be tricky. Some materials cannot withstand the harsh environments found in industrial applications. This struggle necessitates more R&D investment to find viable alternatives while ensuring functionality. The convergence of these technologies demands a deeper reflection on how we design and install industrial connectors. Achieving innovation while addressing these challenges is a complex, ongoing process.

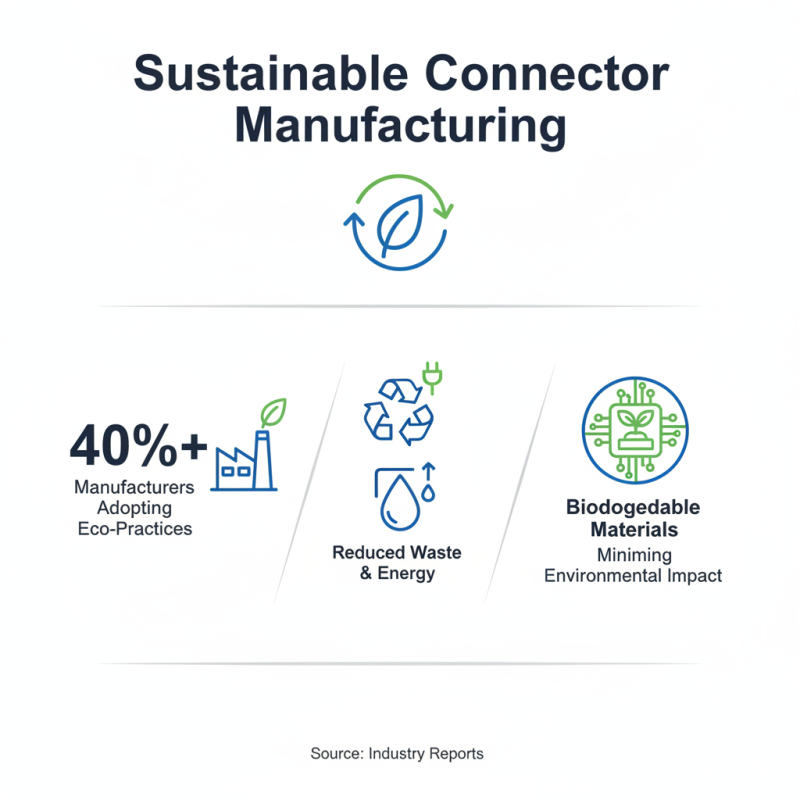

The trend toward sustainability in connector manufacturing is gaining momentum. Reports indicate that over 40% of manufacturers are integrating eco-friendly practices. This shift is crucial in reducing waste and energy consumption. Investing in biodegradable materials is one approach. These materials can decompose naturally, minimizing environmental impact.

Companies are also adopting circular economy principles. This means designing connectors for longevity. By increasing their lifespan, manufacturers can decrease the frequency of replacements. However, there are challenges. Some eco-friendly materials may not perform as well as traditional options. Balancing sustainability with performance is a critical issue.

**Tip**: Consider using connectors that are easy to disassemble. This enhances recyclability.

Renewable energy sources are playing a significant role. Many manufacturers are now using solar or wind energy in production. This transition reduces reliance on fossil fuels. Yet, implementing new energy sources can be costly and complicated for some businesses.

**Tip**: Conduct a sustainability audit. It helps identify areas for improvement.

Overall, the drive for greener practices in connector manufacturing is promising. Continued innovation will be necessary to overcome existing barriers.

High-speed data transfer is becoming essential in industrial connectors. As industries evolve, the need for faster communication is critical. Devices are interconnected, demanding robust solutions. High-speed connectors can significantly improve efficiency. They help to transmit data quickly and accurately, reducing downtime and enhancing productivity.

When choosing connectors, consider the environment. Harsh conditions can affect performance. Vibrations, dust, and moisture can lead to failures. Make sure to select connectors rated for your specific needs. This will save time and money in the long run.

Tips: Regularly test your connectors. Look for signs of wear and tear. Ensure that they meet the latest standards. Upgrading to newer connector technologies can also prevent obsolescence. Staying informed about industry trends is key. This way, you can adapt and remain competitive.

| Trend | Description | Impact on Industry | Future Outlook |

|---|---|---|---|

| High-Speed Data Transfer | Emphasis on connectors that support faster data rates, facilitating rapid data exchange between devices. | Enhances productivity and efficiency across industrial applications. | Increasing demand as industries embrace automation and data-driven solutions. |

| Miniaturization | Development of smaller connectors without compromising performance, catering to space-constrained environments. | Enables more compact designs and increased functionality in limited spaces. | Expected growth as industries prioritize space-saving solutions. |

| Smart Connectors | Integration of sensors and intelligence within connectors for real-time monitoring and diagnostics. | Improves maintenance efficiency and reduces downtime. | Will see increasing implementation in smart factories and IoT applications. |

| Environmental Sustainability | Focus on connectors made from recyclable materials and environmentally friendly manufacturing processes. | Supports corporate sustainability goals and environmental regulations. | Expected to become a standard practice in connector manufacturing. |

| Increased Ruggedness | Development of connectors that can withstand harsh environments, such as extreme temperatures, dust, and moisture. | Enhances reliability in critical applications such as aerospace and manufacturing. | Growing need for durable solutions across various sectors. |

Smart connectors are transforming industrial landscapes in 2026. The blend of IoT and Industry 4.0 is creating dynamic environments. Reports indicate that the smart connector market could surpass $20 billion by 2026. These connectors enable seamless data transfer, enhancing operational efficiency. Real-time monitoring is becoming standard practice.

Organizations must focus on integration. Connectivity is crucial for harnessing IoT benefits. Many industries face challenges in interoperability. Incompatibility often hinders full adoption of smart technologies. According to industry studies, 30% of organizations struggle with integrating new systems. Solutions need to address these gaps to maximize potential.

Tips: Start small with pilot projects. Testing smart connectors in controlled environments can help identify issues. Collaboration among teams can enhance understanding and effectiveness. Regular assessments are essential to adapt to rapid technological changes.

The connector industry is experiencing notable shifts. Market dynamics are influenced by technological advancements and evolving consumer demands. According to a recent report, the global connector market is projected to grow at a CAGR of 5.2% from 2023 to 2028. This growth underscores the importance of understanding key players and their competitive strategies.

Major players focus on developing innovative solutions. They invest heavily in research and development to stay ahead. Specialized connectors for the automotive and medical sectors are gaining traction. These connectors require precision and reliability. Reports indicate that demand in these sectors is expected to rise significantly, but the supply chain remains a challenge.

Competitive landscapes are ever-changing. Smaller companies are emerging, challenging established firms. They offer specialized products at competitive prices. This has led to a pricing war, which might compromise product quality. As companies navigate these trends, they must also rethink their strategy. Maintaining quality while reducing costs is not easy, but essential for survival. Understanding these market dynamics is key for success in the connector industry.