In the rapidly evolving landscape of industrial applications, choosing the right industrial connector has become a critical decision for businesses seeking to optimize performance and reliability. Industrial connectors play a crucial role in ensuring efficient connections between various machinery and components, accommodating a vast array of requirements across diverse sectors. As technology advances and industries become increasingly interconnected, understanding the specific demands of your application is essential to select the most suitable connector.

This guide aims to provide a comprehensive overview of the key factors to consider when selecting industrial connectors tailored to your unique needs. By delving into vital aspects such as environmental conditions, electrical specifications, and mechanical durability, we will equip you with the knowledge necessary to make informed decisions. Ultimately, the right industrial connector can significantly impact operational efficiency, reduce downtime, and enhance the overall safety of your systems. Join us as we explore the essential criteria that will guide you in making the optimal choice for your industrial applications in 2025.

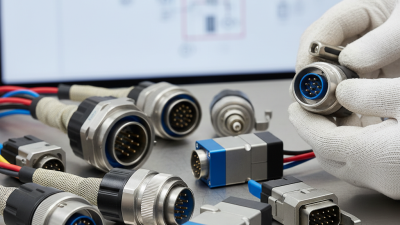

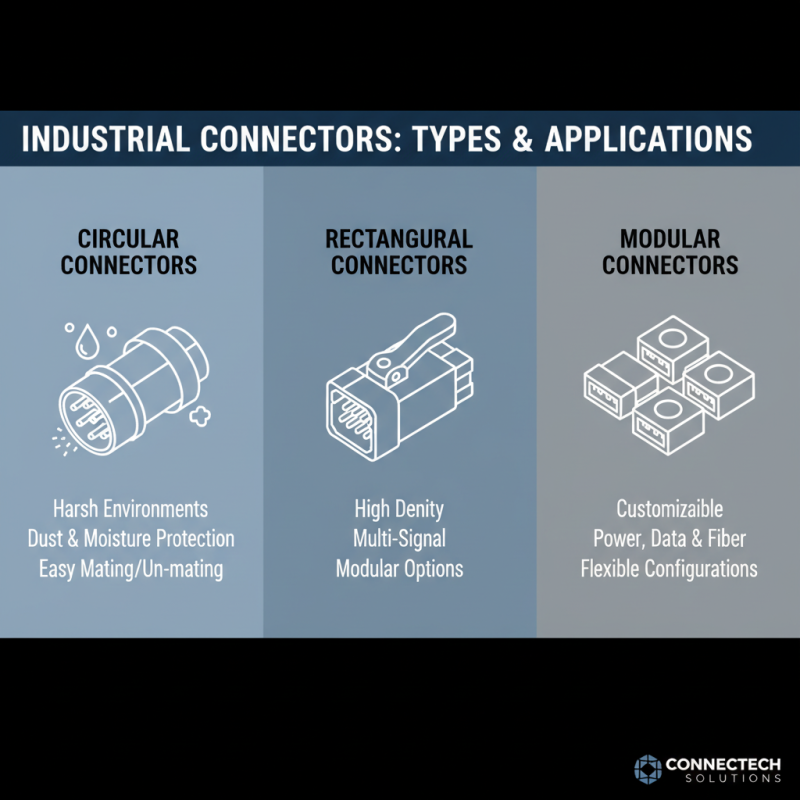

When selecting the right industrial connector for your specific application, understanding the various types available is crucial. Industrial connectors can be broadly categorized into several types, including circular connectors, rectangular connectors, and modular connectors. Circular connectors, often used in harsh environments, provide excellent protection against dust and moisture, making them ideal for outdoor applications. Their design allows for easy mating and un-mating, which facilitates quick assembly and disassembly during maintenance or repairs.

Rectangular connectors, on the other hand, offer versatility in terms of pin configuration and size. They are commonly used in applications requiring more complex wiring arrangements, as they can accommodate a larger number of pins in a compact space. This type of connector is prevalent in control panels and automation systems where space is a premium and reliability is essential. Modular connectors are another option, allowing users to customize their connector solution by choosing different modules based on the specific requirements of their application, such as data transfer, power supply, or signal transmission.

Each type of industrial connector is designed to meet specific standards and environmental challenges, such as temperature fluctuations, vibration, and electromagnetic interference. Understanding these different options and their unique properties will help you make an informed decision, ensuring that the chosen connector will cater to your needs effectively and enhance the overall reliability of your industrial system.

When selecting industrial connectors for your application, one of the foremost factors to consider is the environmental conditions where the connector will be used. Factors such as temperature fluctuations, humidity levels, and exposure to dust or chemicals can significantly influence the longevity and functionality of the connector. For example, connectors designed for extreme temperatures may have specific materials and sealing technologies to ensure performance under harsh conditions. Understanding the specific environment will guide you in choosing connectors that can withstand various stressors and maintain reliable connections.

Another critical factor is the electrical requirements of your application. This includes current rating, voltage rating, and specific signal types. Different applications may require connectors that can handle varying levels of power and data transfer. It is essential to assess the amperage and voltage levels to select connectors that not only meet but exceed these specifications to prevent overheating and failures. Additionally, consider the connector’s design, such as the number of pins and layout, which should match your system’s configuration for optimal connectivity and performance.

When selecting the appropriate industrial connector, assessing electrical ratings is crucial for ensuring reliable performance in your specific application. The primary electrical ratings to evaluate include current, voltage, and frequency.

Current rating indicates the maximum amount of electrical current the connector can carry without overheating and causing failure. It is essential to choose a connector with a current rating that exceeds the expected load to accommodate any temporary surges that may occur during operation.

Voltage rating is equally significant, as it defines the maximum voltage a connector can handle safely. Exceeding this voltage can lead to breakdown or flashover, potentially damaging the connector and compromising system safety.

It’s important to assess the working voltage of your equipment and choose connectors that can manage both the operating voltage and any potential transients that might arise in your system. Frequency considerations should not be overlooked either. Connectors used in applications with alternating current (AC) may require specific designs that can effectively handle the frequency of operation, ensuring stability and performance over time.

Understanding these factors will lead to more informed decisions and enhance the efficiency and safety of your industrial processes.

When selecting industrial connectors, material selection plays a pivotal role in ensuring longevity and performance in various environments. Industrial connectors are subjected to harsh conditions, including extreme temperatures, moisture, and exposure to chemicals. Therefore, the choice of materials—such as metals, plastics, and elastomers—should be guided by the specific demands of the application. For example, connectors made from stainless steel offer superior corrosion resistance, while those made from high-grade thermoplastics can withstand high mechanical stress without yielding.

Equally important is understanding the environmental resistance properties of the materials used in industrial connectors. Connectors used in outdoor settings should have UV resistance to prevent degradation from sunlight exposure, while those in humid or wet environments benefit from waterproof ratings. Additionally, connectors that will be exposed to chemicals must be compatible with those substances to avoid premature failure. Evaluating factors like temperature range, ingress protection ratings, and chemical resistance ensures that the chosen connectors will not only fit the immediate needs but also provide reliable performance throughout their operational lifetime.

| Connector Type | Material | Environmental Resistance | Temperature Range (°C) | IP Rating | Durability (Cycles) |

|---|---|---|---|---|---|

| Circular Connector | Aluminum Alloy | Water Resistant | -40 to 85 | IP67 | 500 |

| Rectangular Connector | Polyamide | UV Resistant | -20 to 100 | IP65 | 1000 |

| Fiber Optic Connector | Stainless Steel | Chemical Resistant | -40 to 70 | IP68 | 2000 |

| USB Connector | Plastic | Moisture Resistant | 0 to 70 | IP54 | 3000 |

| D-sub Connector | Zinc Alloy | Shock Resistant | -40 to 85 | IP67 | 1000 |

When selecting industrial connectors, understanding the relevant industry standards and certifications is crucial to ensure compatibility and reliability. Several standards govern the design and performance of connectors, such as IEC 61076, which outlines specifications for circular connectors in industrial environments. Familiarity with these standards helps in selecting connectors that meet the necessary requirements for harsh conditions, including moisture, dust, and extreme temperatures. Additionally, certifications such as UL (Underwriters Laboratories) and CE (Conformité Européenne) can provide assurance regarding the safety and compliance of connectors used in various applications, ensuring they meet international safety guidelines.

Moreover, it is essential to consider specific certifications that pertain to the intended application. For instance, connectors used in explosive atmospheres should comply with ATEX or IECEx standards, which guarantee that the connectors operate safely in hazardous environments. Similarly, connectors used in marine applications might require certifications from class societies to ensure they can withstand the unique challenges posed by saltwater and humidity. By prioritizing the right standards and certifications, designers and engineers can make informed decisions that not only enhance system reliability but also contribute to overall operational efficiency.